Purge Solenoid Valve: A Detailed Technical Article

Introduction

In the arena of automotive technology, there is a multitude of integral components that make vehicles function optimally. Among these is the relatively lesser-known but significantly important, purge solenoid valve. The function of this component is to manage the emissions system within a vehicle, specifically playing a key role in controlling the release of fuel vapors.

What is a Purge Solenoid Valve?

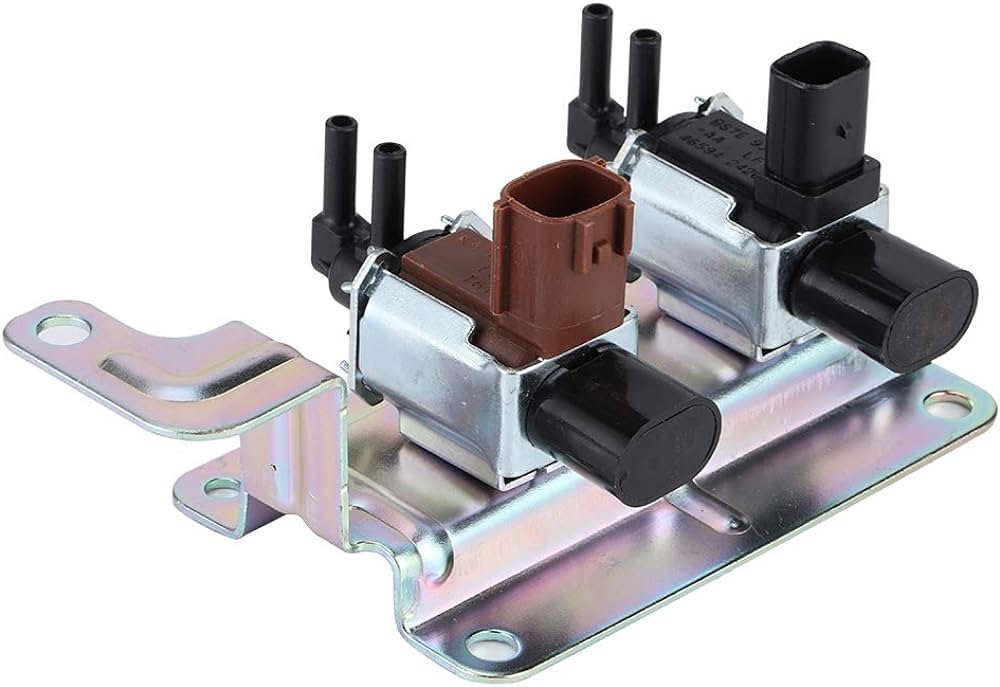

Commonly identified as a purge valve, evap purge valve, or vapor canister purge valve, the purge solenoid valve serves as an integral part of the vehicle’s Evaporative Emission Control System (EVAP). Its primary responsibility involves directing fuel vapors from the fuel tank to the engine’s intake manifold. It is a well known type of soleniod valves.

This function ensures combustion of the vapors, thereby preventing the release of harmful hydrocarbon emissions into the environment. When the engine is operational and warm, the canister purge valve – an alternate name for the purge valve solenoid – is typically activated. This process plays a significant role in maintaining a vehicle’s optimal performance and mitigating environmental pollution.

What does a Purge Solenoid Valve do?

The purge solenoid valve, often referred to as an evap purge valve, serves several pivotal functions in a vehicle’s emissions system:

- It plays an integral role in the Evaporative Emission Control System (EVAP). This system is designed to contain and recycle fuel vapors rather than releasing them into the atmosphere. As part of this system, the purge evap valve helps to regulate the flow of these vapors, aiding in the reduction of harmful emissions.

- During periods when the engine is idle or not fully warmed up, the purge solenoid valve remains closed, preventing the flow of fuel vapors from the charcoal canister to the engine. This helps in reducing fuel wastage.

- Once the engine has reached operational conditions—like specific speed, load, and temperature thresholds—the purge solenoid valve is activated by the engine control unit (ECU). At this point, the valve opens, and the fuel vapors stored in the canister are allowed to flow into the engine’s intake manifold for combustion.

- It ensures a precise flow of fuel vapors. Based on real-time data and engine conditions, the ECU instructs the purge solenoid valve to adjust its opening, modulating the volume of fuel vapors that reach the engine. This function helps in maintaining the ideal air-fuel ratio required for efficient combustion, thus optimizing engine performance and fuel efficiency.

- In cases of abnormal conditions or malfunctions in the system, the purge solenoid valve interacts with the vehicle’s onboard diagnostic system. A faulty valve or any disruptions in the valve’s operation can trigger the Check Engine Light, alerting the driver of potential issues within the EVAP system.

Canister purge valve operation

The canister purge valve, also known as the vapor canister purge valve, operates as a control device within a vehicle’s Evaporative Emission Control System (EVAP). The function of the valve is to regulate the flow of fuel vapors from the charcoal canister, where they are stored, to the engine’s intake manifold. This process happens under specific conditions when the engine is running and has reached a certain temperature threshold.

When the engine control unit (ECU) detects these conditions, it sends a signal to the purge valve solenoid which causes the canister purge valve to open. As a result, the fuel vapors in the canister are drawn into the intake manifold, blending with the air-fuel mixture for combustion. This process helps to optimize the vehicle’s fuel efficiency and reduce the release of harmful hydrocarbon emissions into the environment.

On the other hand, when the engine is turned off or is not sufficiently warmed up, the ECU ceases to send the activation signal. Consequently, the canister purge valve remains closed, preventing the flow of fuel vapors into the intake manifold. This aspect of the operation prevents unnecessary fuel wastage when combustion is not required.

Detailed Working Mechanism of the Purge Solenoid Valve

The operational dynamics of the purge solenoid valve involve a delicate yet intricate interface with the engine control unit (ECU). The ECU serves as the ‘command center’ for this valve, guiding its opening and closing based on specific engine conditions.

When the engine is operating within predefined parameters—like certain speed, load, and temperature thresholds—the ECU activates the purge solenoid, which prompts the valve to open. Consequently, the stored fuel vapors in the canister are released and directed towards the intake manifold. These vapors then journey into the combustion chamber of the engine, where they are ignited and effectively burned off as part of the combustion cycle.

In contrast, when the ECU determines that the engine conditions have strayed from the ideal parameters, it instructs the purge solenoid to cease operation. This action results in the closing of the valve, thus barring the passage of any more fuel vapors into the intake manifold. This cycle of operation, controlled by the ECU based on the real-time conditions of the engine, helps ensure optimal engine performance, fuel efficiency, and a reduction in harmful emissions.

Overall, the purge solenoid valve is a critical component that ensures the seamless transfer of fuel vapors from the canister to the combustion chamber, maintaining an ecological balance while achieving optimal engine performance.

Potential Issues and Symptoms of a Faulty Purge Solenoid Valve

In this section, we will delve into the potential issues that may arise from a malfunctioning purge solenoid valve. We will also identify the signs and symptoms to watch out for, aiding you in the early detection of a possible failure.

What are the common causes of failure for a purge solenoid valve?

Common causes of failure for a purge solenoid valve often revolve around natural wear and tear over time, faulty wiring, or clogs from dirt or debris. Regular vehicle maintenance, particularly cleaning and inspection of the valve and its connections, can help to prevent such malfunctions.

Issues with the purge solenoid valve can result in multiple complications, some more noticeable than others. A failing evap purge solenoid valve can manifest itself through a reduction in fuel efficiency, a consequence of the engine compensating for an incorrect air-fuel mixture. The incorrect mixture can be attributed to the purge control valve being stuck open, which allows a continuous flow of fuel vapors into the intake manifold even when it’s not required, causing a rich condition in the engine.

Similarly, if the solenoid evap valve is stuck closed, it can prevent the necessary flow of fuel vapors into the intake manifold during combustion, creating a lean condition in the engine. These engine conditions may trigger the Check Engine Light, providing the driver with a clear indication of a potential issue.

The vehicle failing an emissions test is another clear sign of a faulty purge solenoid valve. As the purge solenoid valve controls the flow of fuel vapors to be combusted, a malfunctioning valve can lead to the emission of harmful hydrocarbons into the environment, resulting in a failed emissions test.

Moreover, idling issues can arise when the purge solenoid valve fails. A valve that’s stuck open or closed can disrupt the engine’s air-fuel mixture, resulting in an unstable idle. Drivers might notice their vehicle experiencing a rough idle, where the engine shakes excessively or the RPMs fluctuate more than usual.

Finally, in more severe cases, issues with the purge solenoid valve can even lead to the vehicle experiencing difficulty starting. This is usually caused by a severely rich condition, where excess fuel vapors flood the engine, preventing normal combustion and thus, inhibiting the start-up process.

By staying vigilant for these symptoms, one can proactively identify a faulty purge solenoid valve and take necessary measures to rectify the issue, thereby ensuring optimal vehicle performance and minimizing environmental impact.

Importance of Regular Maintenance and Timely Replacement

Consistent inspection and maintenance of the evap purge solenoid valve are imperative in order to sidestep the challenges previously mentioned. With time, accumulations of dirt and particles can lead to obstruction in the purge valve, thus interfering with its operation and potentially leading to harm to other constituents of the EVAP system. Equally, a jammed or damaged purge control valve can contribute to a rise in emissions, causing negative environmental impacts and potential violation of emission regulations.

To ensure the purge solenoid valve functions optimally, regular checks are advised, specifically when symptoms of a malfunctioning valve become apparent. In cases where the valve is found to be defective, prompt replacement is paramount in preventing further damage to the vehicle’s emissions system and guaranteeing optimal vehicle performance. Implementing these measures can help sustain the efficiency and reliability of your vehicle while also contributing to environmental conservation.

In essence, proactive maintenance and timely replacement of the purge solenoid valve can play a significant role in maintaining the performance integrity of your vehicle, ensuring regulatory compliance and contributing to environmental preservation efforts.

How to Clean a Purge Solenoid Valve

While this blog post provides a basic overview on cleaning your purge solenoid valve, it’s always recommended to seek the help of a professional mechanic to handle this maintenance task, particularly if you’re not confident in doing it yourself. Properly cleaning this component requires precision and a deep understanding of your vehicle’s systems, hence a professional’s expertise is invaluable.

Cleaning your purge solenoid valve is an essential aspect of vehicle maintenance that helps maintain fuel efficiency and reduce harmful emissions. Here’s a step-by-step guide on how to clean a purge solenoid valve:

- Disconnect the Vehicle: Start by disconnecting the battery to ensure safety while working with vehicle components.

- Locate the Valve: Identify the location of the purge solenoid valve, often positioned near the engine’s intake manifold and attached to the charcoal canister of the EVAP system. The valve is also referred to as the canister purge valve or vapor canister purge valve.

- Remove the Valve: Detach the purge solenoid valve from the engine using the appropriate tool, typically a screwdriver or wrench. Carefully disconnect the vacuum lines and electrical connectors attached to the valve.

- Clean the Valve: Using a canister cleaner, spray the purge solenoid valve and its openings to remove any dirt, debris or carbon build-up. Gently clean the valve with a brush if needed. Ensure you avoid using aggressive cleaning agents that may damage the valve’s components.

- Dry the Valve: After cleaning, allow the purge solenoid valve to air dry completely. This prevents moisture from interfering with the valve’s function.

- Reinstall the Valve: Once dry, reattach the purge solenoid valve to the engine. Ensure all vacuum lines and electrical connectors are correctly secured.

- Test the Valve: Reconnect the battery and start the vehicle to test the operation of the freshly cleaned purge solenoid valve.

Following these steps regularly helps ensure the optimal performance of the purge solenoid valve, maintaining the efficiency of your vehicle’s EVAP system, and contributing to environmental conservation.

Electrical connection troubleshooting for the purge solenoid valve

While this blog post provides a basic overview on cleaning your purge solenoid valve, it’s always recommended to seek the help of a professional mechanic to handle this maintenance task, particularly if you’re not confident in doing it yourself. Properly tsoubleshooting this component requires precision and a deep understanding of your vehicle’s systems, hence a professional’s expertise is invaluable.

Troubleshooting the electrical connection of the purge solenoid valve involves a few key steps. Firstly, ensure the vehicle is turned off and disconnected from its power source. Safety is paramount when dealing with electrical systems.

Begin by locating the purge solenoid valve. It’s generally positioned near the engine’s intake manifold and is attached to the charcoal canister of the EVAP system. The valve is typically linked to the engine control unit (ECU) through an electrical harness.

Next, inspect the wiring harness that connects the purge solenoid valve to the ECU. Look for any signs of damage, corrosion, or loose connections. Any of these issues could disrupt the electrical signals between the ECU and the valve, leading to malfunction. If the harness appears to be in good condition, the next step is to check the electrical operation of the evap purge valve itself. This involves testing for resistance using a multimeter.

Disconnect the valve’s wiring harness and attach the multimeter’s probes to the terminals on the valve. Compare the reading to the manufacturer‘s specifications. Any significant deviation indicates a faulty purge solenoid valve.

Remember, when conducting these tests, to reconnect any disconnected components and return the vehicle’s settings to their original state. If the tests identify a problem with the electrical connections or the valve itself, consult a professional mechanic or consider replacing the valve.

The regular inspection of the electrical connection of your purge solenoid valve helps ensure the optimal performance of your vehicle’s EVAP system and contributes to an overall reduction in harmful emissions.

How to Choose a High-Quality Purge Solenoid Valve

Selecting an exceptional purge solenoid valve requires a methodical approach considering several key parameters. Initially, it is crucial to verify the valve’s compatibility with your specific vehicle make and model. This ensures that the new component will integrate seamlessly with your vehicle’s Evaporative Emission Control System (EVAP), maximizing operational efficiency.

Equally significant is the reputation of the valve’s manufacturer. Purchasing from a recognized and respected manufacturer offers assurance of the valve’s quality, reliability, and performance. Do research into the manufacturer’s track record in producing durable and efficient purge valves.

The construction material of the purge valve solenoid should also be a point of consideration. Materials that demonstrate resistance to wear and tear, can endure harsh operating conditions, and exhibit resilience against environmental elements, such as dust and debris, are preferable. Such materials are likely to enhance the valve’s lifespan, ensuring extended periods of optimal function.

Additionally, pay heed to the warranty offered by the manufacturer. A comprehensive warranty can provide a safety net, protecting you against unforeseen manufacturing defects or operational issues with the purge valve. Such a warranty is a testament to the manufacturer’s confidence in their product’s durability and performance.

By keeping these factors in mind, you can ensure that you’re selecting a high-quality purge solenoid valve that contributes effectively to the performance of your vehicle’s emission system, maintains regulatory compliance, and supports environmental conservation efforts.