The Role of Ball Valve Parts: Regulating Pressure

Table of Contents

ToggleIntro

Ball valve parts are essential pieces, each serving a unique function, work together in harmony to ensure efficient flow control and pressure regulation. Understanding the parts that make up a ball valve and their roles can provide insight into how to optimize fluid handling systems and maintain them effectively.

Understanding the Ball Valve Parts

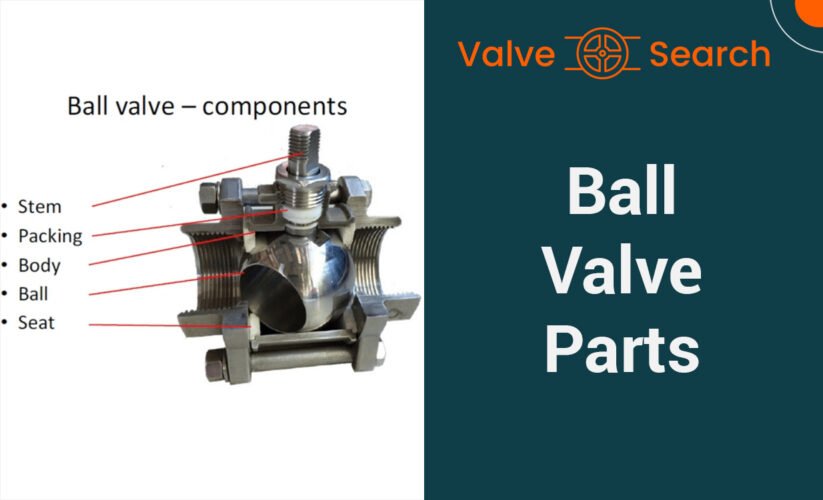

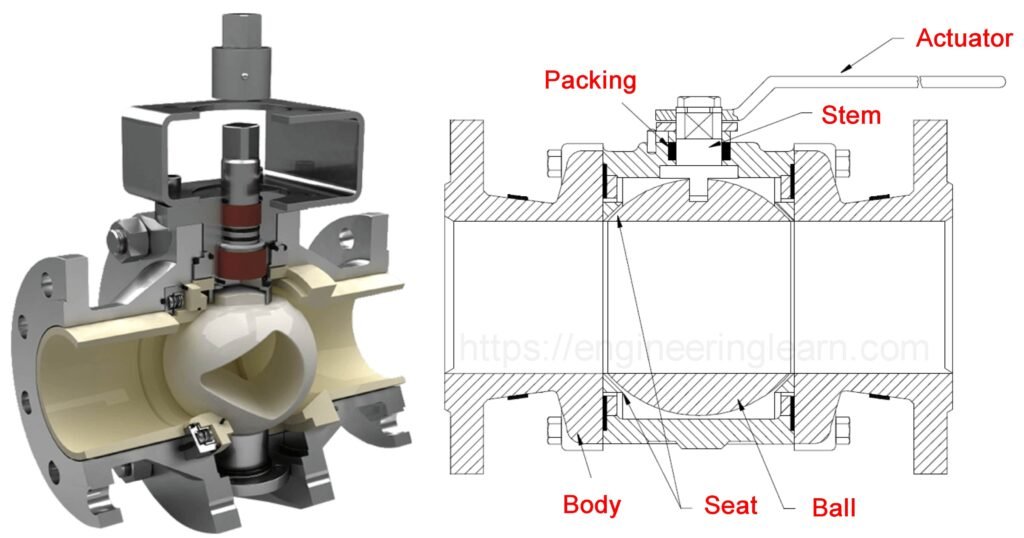

Ball valves, much like their name implies, are designed around a spherical component, yet there are many other parts that contribute to their functionality. The primary elements of a ball valve consist of the central ball, a seal or seat, a stem, and the encompassing body. Together, these form the integral ball valve assembly.

Developing a solid comprehension of ball valve parts, their roles, and how they interact is essential in performing successful troubleshooting and maintenance. Additionally, it’s a critical step in understanding how the ball valve internals exert influence over flow control and the regulation of pressure.

How ball valve parts can impact maintenance and repair costs

Ball valve parts directly influences the long-term maintenance and repair costs of your fluid control system. Consider the following factors:

- Materials Selection:

- Durable materials like stainless steel or brass are commonly used for ball valve parts. These materials resist wear and tear, reducing the need for frequent replacements and repairs.

- Materials Selection:

- Complexity of Design:

- However, sophisticated designs often offer superior control and efficiency, potentially offsetting increased maintenance costs by reducing operational expenses.

The complexity of a ball valve’s design affects maintenance costs. Intricate parts or mechanisms may require specialized knowledge or tools for servicing, leading to higher expenses.

- Complexity of Design:

- Ease of Maintenance:

- Design features that allow easy disassembly or access to internal components facilitate regular checks and maintenance. This saves time and labor costs.

- Ease of Maintenance:

- Innovation and Technology:

- Modern ball valve designs incorporate smart technologies. These valves can self-diagnose potential issues and enable preventative maintenance, ultimately saving on repair bills over time.

- Innovation and Technology:

In summary, thoughtful consideration of ball valve parts directly impacts the cost of maintaining your fluid control system. When choosing a ball valve, balance upfront costs with potential long-term savings from reduced maintenance and repair expenses.

Ball Valve Diagram

A ball valve diagram provides a clear and detailed visualization of the various ball valve parts and how they come together to form the whole assembly. This visual aid can be particularly beneficial in understanding the internal workings of a ball valve. At the center of the diagram, you’ll find the ball, identifiable by its characteristic spherical shape and a hole running through its middle.

The ball is enclosed by the seal, forming a snug fit that ensures efficient flow control. Extending from the ball is the stem, acting as a conduit between the handle or actuator and the ball. Encasing all these internal parts is the valve body, providing a sturdy housing and a protective barrier against the fluid passing through the valve.

By studying a ball valve diagram, you can gain a deeper understanding of the intricacies of each component and how they collectively contribute to the effective regulation of fluid flow within your system.

The Core Part: Ball

The ball is the namesake and central component of a ball valve, known for its distinct spherical shape with a strategically placed hole. This hole is not randomly placed but is aligned with the flow direction of the fluid when the valve is fully open, facilitating unobstructed passage of fluid. However, the game-changing function of the ball emerges when it’s rotated. In this scenario, the hole is no longer in line with the flow direction, acting as a barricade to fluid movement and effectively shutting off the flow.

This pivotal feature of the ball equips the valve with a powerful capacity for fluid flow regulation. It allows not only for maximum flow but also a complete halt, providing an exceptional degree of control over the fluid management system.

The Seal: Ensuring Efficiency and Avoiding Leaks

Enveloping the ball in a ball valve is a component known as the seal, or the valve seat. Crafted typically from a resilient material with a bit of ‘give’, this part creates a secure seal against the ball. This becomes particularly crucial when the valve is in a closed position, blocking the flow of fluid. The efficiency of the ball valve is closely linked to the condition and quality of this seal.

A seal in prime condition assures a close-fitting shutoff. This effectively safeguards against undesirable leaks and preserves the pressure within the system. The seal, therefore, has a significant impact on the valve’s operational effectiveness and, by extension, the overall efficiency of the fluid handling system.

The Valve Stem: Maintaining Precise Control

Integral to the operation of a ball valve is the stem. It forms a crucial link between the valve’s handle or actuator and the central ball component. As the primary facilitator of the ball’s movement, the stem grants the capacity to manipulate the valve, shifting it from open to closed states. Through this pivotal function, the stem permits an exceptional degree of control over the fluid flow within the system.

This part’s role in pressure regulation is not to be underestimated. It is the stem’s smooth operation that facilitates precise control of the ball’s position, and by extension, the rate of fluid flow. A stem of high-quality construction contributes to a well-functioning valve and ultimately, a well-regulated fluid system.

The valve stem’s importance underlines the need for quality materials and design in its construction. Not only does it need to withstand the physical demands of controlling the ball’s rotation, but it also must resist wear and tear over time to maintain its function. Quality design and materials in the stem ensure precision in control, optimal flow regulation, and overall longevity of the ball valve.

In essence, the stem is the backbone of the valve’s function, without which the ball would be incapable of performing its flow regulation task. Therefore, when considering the overall performance and efficiency of a fluid handling system, one must not overlook the essential role of the valve stem.

The Valve Body: Handling Corrosive Fluids

The enclosure of a ball valve, aptly referred to as the valve body, is the primary housing for all its components. This vital piece forms the direct contact point with the fluid coursing through the system. Therefore, it is essential that the valve body is built to last, specifically designed to resist the detrimental effects of corrosion. This is especially critical when dealing with potentially corrosive fluids. The choice of material used in the valve body can have a significant impact on the life expectancy of the valve, as well as the overall performance of the fluid control system. For instance, stainless steel or brass bodies are often employed for their high corrosion resistance.

The construction of the valve body should also prioritize structural integrity to securely contain the internal components under various operating pressures. In short, the durability and design of the valve body are pivotal in preserving the longevity and reliability of ball valve operations. By meticulously considering the corrosive nature of the fluids in the system, and adjusting the valve body design and material accordingly, you can significantly improve the ball valve’s life cycle and your system’s overall operational performance.

Beyond the Basics: Innovations in Ball Valve Design

The realm of ball valve design is not static but continuously evolving, with cutting-edge improvements targeting efficiency enhancement and longevity of the valve. One of these innovations includes the development of superior materials tailored for increased resistance against corrosion. This extends not only to the valve body but also to the other ball valve components, providing them with a robust defense against the damaging effects of corrosive fluids. Another area of innovation is the redesigning of seal mechanisms.

Modern designs focus on more effective leakage prevention, further securing the efficiency of ball valves. Perhaps one of the most significant advances is the integration of smart technologies into the valve design. These technologies allow for automated control, eliminating the need for manual manipulation and significantly reducing the margin for human error. Additionally, diagnostic capabilities can identify potential issues before they escalate, facilitating preventive maintenance and ultimately extending the life of the valve.

These technological advances represent a leap forward, not only in enhancing valve functionality but also in boosting the overall operational performance of fluid management systems. The future of ball valve design undoubtedly holds more groundbreaking innovations, as we continue to push the boundaries of efficiency, control, and durability.

What are some common issues that can occur with ball valve parts, and how can they be resolved?

These problems could range from a total valve failure to more minor issues such as leaking, all of which can hinder a ball valve’s efficiency. Therefore, proper maintenance and prompt repairs are vital for avoiding these issues. Understanding the various parts of a ball valve, such as the ball, stem, and seals, can help identify problems early on. Routine inspections of these components can prevent failures and prolong the valve’s life. Furthermore, ensuring that these parts are adequately lubricated can prevent damage caused by friction, which can impair the functionality of the valve. Scheduling regular maintenance can help avoid common ball valve issues and significantly enhance the lifespan and reliability of your system.

FAQ – Ball Valve Parts

- Q: What materials are commonly used for ball valve parts?

- A: Ball valve parts are typically made from durable and corrosion-resistant materials such as stainless steel or brass. These materials are known for their strength and longevity.

- Q: What materials are commonly used for ball valve parts?

- Q: What is the function of the ball in a ball valve?

- A: The ball is the central component of a ball valve. When the valve is open, the ball’s hole aligns with the flow direction, allowing fluid to pass through. Rotating the ball shuts off the flow by misaligning the hole.

- Q: What is the function of the ball in a ball valve?

- Q: How does the stem contribute to the functionality of the ball valve?

- A: The stem connects the valve’s handle or actuator to the ball. It facilitates ball movement, regulating fluid flow through the valve.

- Q: How does the stem contribute to the functionality of the ball valve?

- Q: What role does the valve body play in handling corrosive fluids?

- A: The valve body houses all components and directly contacts the fluid. It’s crucial that the valve body is designed to resist corrosion, especially when dealing with corrosive fluids.

- Q: What role does the valve body play in handling corrosive fluids?

- Q: What kind of maintenance does a ball valve require?

- A: Regular inspections for leaks and potential corrosion are crucial. Adequate lubrication of the ball, stem, and seals can prevent damage due to friction. Proactive maintenance extends the life expectancy of your ball valve assembly.

- Q: What kind of maintenance does a ball valve require?

Conclusion for Ball Valve Parts

In essence, the various ball valve parts all play integral roles in regulating flow and handling corrosive fluids. A clear understanding of these components allows for greater control, efficiency, and longevity in fluid management systems.

- The Ball: This central component controls the flow by rotating within the valve body. Its spherical shape ensures a tight seal when closed and allows for smooth flow when open.

- The Seal: The sealing mechanism prevents leaks. It ensures a watertight closure when the ball is in the shut position.

- The Stem: Connected to the ball, the stem enables precise control. Turning the stem opens or closes the valve.

- The Body: The outer casing houses the ball, stem, and seal. It provides structural support and determines the valve’s overall durability.

Continual advancements in ball valve design promise more resilient, efficient, and smarter components, further enhancing system performance. Ultimately, proper understanding, maintenance, and use of ball valve parts significantly contribute to the efficient and effective management of fluid flow systems.