Double Eccentric Butterfly Valves: 3 Common Misconceptions Debunked

Table of Contents

ToggleDebunking Common Misconceptions About Double Eccentric Butterfly Valves

Are you curious about double eccentric butterfly valves and how they can benefit your industry? In this blog post, we will debunk common misconceptions and explore the advantages of double eccentric butterfly valves. Often overlooked in the water industry, these valves offer leak-free design, eliminate the need for an exercise program, and provide versatility for various applications. Join us as we delve into the ins and outs of double eccentric butterfly valves and uncover the valuable solutions they offer for your projects and operations.

Exploring Double Eccentric Butterfly Valves

What Is a Double Eccentric Butterfly Valve?

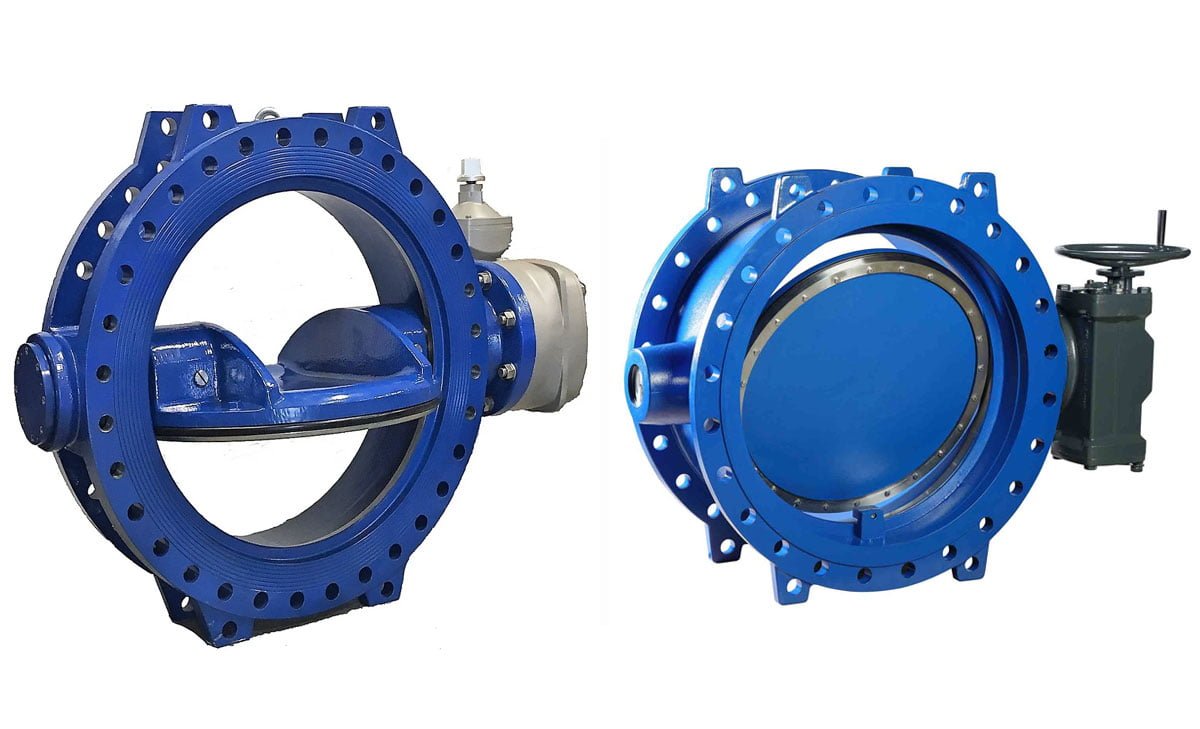

A double eccentric butterfly valve is a type of quarter-turn valve that is designed with a circular disc and a metal seat. It operates by rotating the disc to control the flow of the fluid. Unlike the single eccentric butterfly valve, the double eccentric design features a disc that is placed slightly off-center from the shaft, allowing for a more precise and efficient shut-off.

Double Eccentric Butterfly Valve Design

The double eccentric butterfly valve design comprises several key components, including the disc, shaft, seat, and actuator. The disc is typically made of metal and has a slight offset from the shaft, which helps in reducing wear and tear on the seat. The seat, often made of resilient material, provides a tight seal when the valve is in the closed position. Additionally, the actuator, which can be manual or automated, controls the movement of the disc to regulate flow.

The Engineering Behind the Double Offset

The term “double offset” refers to the fact that the disc’s center axis is offset from the shaft and the centerline of the pipe. This design feature offers significant advantages, such as reduced friction during operation and improved sealing performance. The double offset configuration allows for a bubble-tight shut-off, making it highly effective for applications requiring precise flow control and reliable isolation.

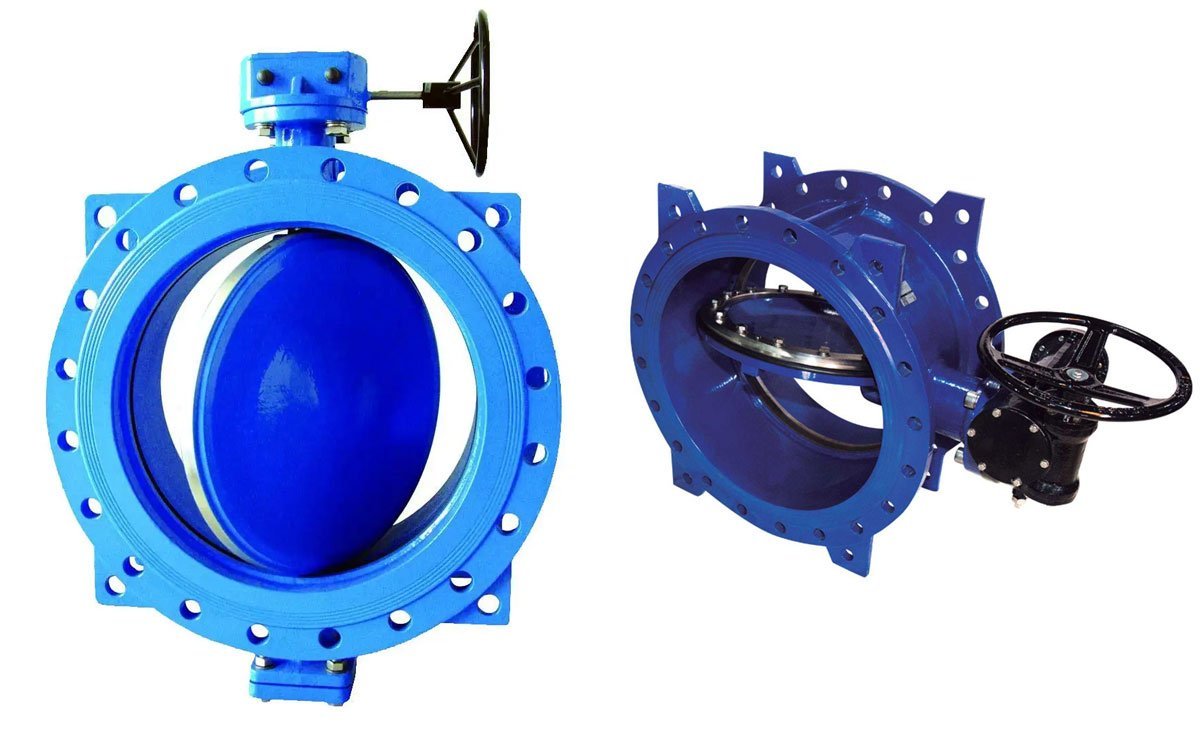

Difference Between Concentric and Double Eccentric Butterfly Valve

While the concentric butterfly valve has a symmetrical disc centered on the shaft, the double eccentric butterfly valve has a disc positioned off-center. This fundamental difference allows the double eccentric design to provide better sealing capabilities, minimal friction, and improved resistance to wear. In comparison, the concentric design may be more prone to seat wear and less effective in high-performance applications that demand tight shut-off capabilities.

Addressing Common Doubts

Many misconceptions surround double eccentric butterfly valves, leading to confusion and misinformation. It’s time to debunk these myths and set the record straight.

Myth: Double Eccentric Butterfly Valves Are Prone to Leakage

Contrary to popular belief, double eccentric butterfly valves are designed to minimize leakage. Their innovative structure and sealing mechanism ensure a tight seal, reducing the risk of leakage to a minimum. This misconception may stem from outdated information or generalizations about butterfly valves as a whole.

Myth: Double Eccentric Butterfly Valves Are Not Durable

This myth overlooks the advancements in materials and engineering that have greatly improved the durability of double eccentric butterfly valves. Modern manufacturing techniques and high-quality materials make these valves highly resilient and capable of withstanding demanding operating conditions.

Myth: Double Eccentric Butterfly Valves Are Unsuitable for High-Pressure Applications

While some may question their suitability for high-pressure environments, double eccentric butterfly valves are designed to handle substantial pressure with ease. Their robust construction and precise engineering make them a reliable choice for applications that require resilience under high-pressure conditions.

It’s crucial to address these misunderstandings and provide accurate information to help readers gain a deeper understanding of double eccentric butterfly valves. This sets the stage for exploring the true capabilities and benefits of these valves in the following sections.

Unpacking the Advantages

Superior Leak Prevention

When it comes to preventing leaks, double eccentric butterfly valves take the lead. Their design and construction ensure a tight seal, minimizing the risk of leakage. This not only enhances operational efficiency but also reduces the potential for environmental hazards and saves costs on maintenance and repairs.

Maintenance Advantages

One major advantage of double eccentric butterfly valves is their low maintenance requirements. The streamlined design and fewer components result in reduced wear and tear, translating to longer service life and minimal need for maintenance. This aspect makes them a cost-effective and reliable choice for various industrial applications.

The Versatility of Double Eccentric Butterfly Valves

These valves are known for their versatility, making them suitable for a wide range of applications. From high-pressure to high-temperature environments, double eccentric butterfly valves demonstrate exceptional performance. Their adaptability and efficient flow control capabilities make them an ideal choice for industries such as oil and gas, water treatment, and manufacturing processes.

Comparing Valve Types

Double Eccentric vs. Traditional Butterfly Valves

When comparing valve types, it’s crucial to understand the differences between double eccentric and traditional butterfly valves. Traditional butterfly valves have a single offset design, which can lead to wear and tear on the seal over time, potentially causing leakage. On the other hand, double eccentric butterfly valves have a more advanced design, with two offsets that reduce friction during operation and minimize wear on the seal. This advanced design enhances the valve’s performance and longevity, making it a more reliable choice in various applications.

When to Choose a Double Eccentric Valve

Choosing a double eccentric valve is ideal when dealing with demanding conditions that require a high level of performance and durability. These valves excel in applications where tight shut-off, high pressure, and high-temperature services are essential. Additionally, double eccentric valves are suitable for systems that handle abrasive or corrosive media, thanks to their robust construction and reliable sealing capabilities. When precision, efficiency, and longevity are paramount, opting for a double eccentric butterfly valve proves to be the optimal choice.

Real-World Applications

Industrial Uses of Double Eccentric Valves

In the industrial sector, double eccentric butterfly valves are extensively utilized for regulating and isolating various fluid media. Industries such as oil and gas, chemical processing, and water treatment rely on these valves for their high-performance capabilities. Their robust construction and reliable operation make them suitable for handling corrosive and abrasive materials, high pressures, and extreme temperatures. The double eccentric design ensures minimal wear and tear, resulting in extended service life, making them indispensable in demanding industrial settings.

Success Stories in Water Management

The use of double eccentric butterfly valves has revolutionized water management practices, contributing significantly to the success stories in this field. Municipalities and water treatment facilities have experienced remarkable improvements in efficiency and reliability by implementing these valves in their systems. The precise flow control and tight shut-off capabilities of double eccentric valves have led to optimized water distribution, reduced energy consumption, and minimized leakage. As a result, water management organizations have achieved substantial cost savings and enhanced environmental sustainability through the superior performance of these valves.

Installation and Operation Insights

Best Practices for Installing Double Eccentric Valves

Installing double eccentric butterfly valves requires careful attention to detail to ensure optimal performance. Start by thoroughly inspecting the valve and all associated components for any signs of damage or defects. Properly align the valve with the pipeline to prevent stress and distortion. Use high-quality gaskets and ensure proper torque when tightening the bolts to prevent leakage. It’s also crucial to follow the manufacturer’s specific installation guidelines to guarantee a secure and reliable installation.

Operating Tips for Maximum Efficiency

To maximize the efficiency of double eccentric butterfly valves, regular maintenance is essential. Keep the valve and surrounding area clean to prevent debris from interfering with its operation. Monitor the valve for any signs of wear or corrosion and address any issues promptly. Additionally, operating the valve within the recommended pressure and temperature limits will extend its lifespan and ensure consistent performance. Implementing a routine inspection schedule and promptly addressing any maintenance needs will contribute to the longevity and efficient operation of the double eccentric butterfly valve.

Future of Valve Technology

Innovations in Double Eccentric Valve Design

In recent years, the valve industry has witnessed a remarkable surge in innovation, particularly in the realm of double eccentric butterfly valves. Traditional valve designs often faced issues such as fluid leakage and limited durability. However, with advancements in materials engineering and precision manufacturing, the double eccentric butterfly valve has undergone a revolutionary transformation. These innovations have led to the development of valves that offer enhanced performance, greater reliability, and extended lifespans, addressing the challenges that previously plagued conventional valve designs.

The utilization of cutting-edge materials, such as advanced polymers and composite alloys, has significantly bolstered the structural integrity and corrosion resistance of double eccentric butterfly valves. By integrating these materials into the valve’s construction, manufacturers have effectively mitigated the potential for degradation, ensuring prolonged functionality even in demanding industrial environments.

Furthermore, improvements in precision engineering techniques have allowed for the optimization of valve components, resulting in enhanced flow control and reduced energy consumption. The incorporation of streamlined, aerodynamic designs has minimized flow turbulence, subsequently optimizing the valve’s operational efficiency. These innovations have culminated in double eccentric butterfly valves that not only deliver superior performance but also contribute to substantial energy savings, aligning with the industry’s growing emphasis on sustainability.

Predicting Industry Trends

Looking ahead, the future of valve technology, particularly the double eccentric butterfly valve, holds immense promise for further advancements. As industries increasingly prioritize efficiency, safety, and environmental sustainability, the demand for valves that offer uncompromising performance and reliability will continue to soar. This trajectory is expected to fuel ongoing research and development efforts, driving the emergence of innovative materials, manufacturing processes, and digital technologies tailored to enhance valve functionality.

Furthermore, the integration of smart technologies, including sensors and predictive maintenance capabilities, is anticipated to revolutionize valve monitoring and management. By leveraging real-time data analytics and remote monitoring features, operators can proactively address maintenance needs, optimize performance, and preempt potential operational disruptions. This proactive approach not only enhances the lifespan of valve systems but also contributes to cost savings and operational resilience.

In parallel, the digitalization of valve control systems, encompassing the adoption of automated actuators and advanced control interfaces, is poised to streamline operational processes and facilitate seamless integration with industrial automation platforms. This digital transformation holds the potential to redefine operational standards, empowering industries to achieve unprecedented levels of precision, reliability, and adaptability.

In conclusion, the future of double eccentric butterfly valves is marked by ongoing innovation and technological evolution, driven by the imperative to meet and exceed the demands of modern industrial operations. As the industry continues to embrace and anticipate these advancements, the horizon for valve technology appears resplendent with possibilities, promising to redefine operational paradigms and elevate performance benchmarks.

Common Misconceptions About Double Eccentric Butterfly Valves

What is the advantage of using a double eccentric butterfly valve?

This high-performance butterfly valve is ideal for handling water, oil, steam, and gas in a cost-effective, lightweight design. The double-eccentric butterfly valve’s corrosion-resistant, single-component thrust bearing/disc spacer reduces body wear and helps ensure positive centering of the disc in the valve bore.

What are the potential problems with double eccentric butterfly valves?

Common troubleshooting issues with butterfly valves include leakage, which can often be resolved by checking the seals or gaskets, and sticking or binding during operation, which may be caused by debris or corrosion on the disc or within the valve body.

What is the main disadvantage of double eccentric butterfly valves?

The disc of the double eccentric butterfly valve is always present in the path of flow, which can increase the accumulation of debris around the valve, raising the probability of choked flow and cavitation.

What is the difference between concentric and double eccentric butterfly valves?

A concentric (centric) butterfly valve has the stem centered in the middle of the disc and the disc centered in the bore. In contrast, the double eccentric butterfly valve has one or more stems (stub shafts) located offset from the center, classified as double or triple offset valves based on the specific configuration.

Conclusion

In conclusion, it’s clear that double eccentric butterfly valves offer significant advantages over standard butterfly valves. By addressing common complaints such as leakage, seizing, and corrosion, these valves provide a reliable and versatile solution for various applications in the water industry. With their leak-free design and minimal maintenance requirements, double eccentric butterfly valves are a valuable asset for ensuring efficient and dependable operation in water treatment and distribution systems. Consider incorporating these high-performance valves into your projects to experience the benefits firsthand.