The Role of Motorized Butterfly Valves in Process Control Systems

Table of Contents

ToggleFunction and Importance of Motorized Butterfly Valves in Process Control Systems

The role of motorized butterfly valves in process control systems is pivotal to the efficient functioning of various industrial processes. These valves play a crucial part in regulating the flow of fluids and gases in pipelines, ensuring precise control and reliability. In this comprehensive overview, we will delve into the fundamental principles, applications, and advantages of motorized butterfly valves in process control systems. Understanding the significance of these valves is essential for professionals working in industries where fluid or gas flow regulation is critical to operations and safety.

Understanding Process Control Systems

Process control systems are pivotal in the smooth operation of industrial processes, ensuring efficiency, accuracy, and safety. These systems encompass a range of instruments, devices, and software designed to oversee and manage the production process, maintaining optimal conditions and responding to deviations in real time.

Definition and Function of Process Control Systems

Process control systems consist of various components, including sensors, controllers, valves, and actuators, working together to regulate the parameters of a process such as temperature, pressure, flow, and level. The primary function of these systems is to maintain consistency and precision in industrial operations, thereby enhancing productivity and product quality.

Importance of Process Control Systems in Industrial Operations

The significance of process control systems in industrial settings cannot be overstated. These systems play a critical role in ensuring operational stability, minimizing wastage, reducing downtime, and adhering to safety standards. By continuously monitoring and adjusting process variables, they facilitate the seamless functioning of complex production processes, ultimately leading to cost efficiency and enhanced competitiveness in the market.

Introduction to Motorized Butterfly Valves

Definition and Function of a Motorized Butterfly Valve

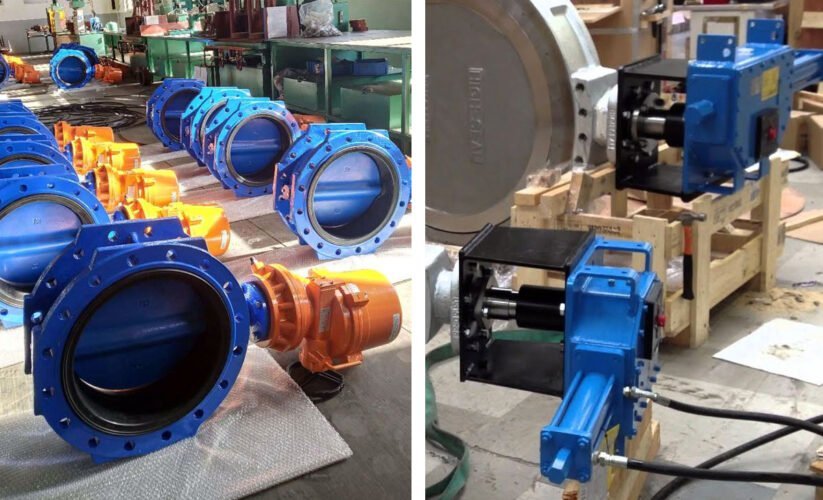

Motorized butterfly valves are essential components in process control systems, designed to regulate the flow of liquids and gases. Their mechanism involves a rotating disc to control the flow of the media, making them crucial for numerous industrial applications. The disc is positioned in the center of the pipe and acts as a damper to effectively modulate the flow, providing precise control over the process. This simple yet efficient design allows for quick operation, making it highly suitable for applications requiring rapid adjustments in flow rates.

Types of Motorized Butterfly Valves

Motorized butterfly valves come in various types to accommodate different operational requirements. These include:

- Concentric Butterfly Valves: The most common type, where the stem is centered in the middle of the valve disc.

- Double Offset Butterfly Valves: Designed with a double offset shaft to reduce wear and extend the valve’s lifespan, making it suitable for high-pressure applications.

- Triple Offset Butterfly Valves: Employing a conical seating design, these valves offer bubble-tight shut-off and are ideal for high-temperature and high-pressure operations.

Advantages of Motorized Butterfly Valves in Process Control Systems

Motorized butterfly valves offer several advantages in process control systems, including:

- Fast Operation: Their simple design enables swift opening and closing, allowing for rapid adjustments in flow rates for precise control over the process.

- Compact and Lightweight: Compared to other valve types, motorized butterfly valves are more compact and lightweight, making them easier to install and requiring less space.

- Cost-Effective: These valves are relatively inexpensive and require minimal maintenance, providing a cost-effective solution for process control applications.

Motorized valves, with their versatility and efficiency, play a pivotal role in ensuring seamless operation and control within industrial processes.

Application of Motorized Butterfly Valves in Process Control Systems

Motorized butterfly valves play a crucial role in process control systems, where their diverse applications contribute to efficient and reliable flow regulation. The integration of motorized butterfly valves in various industries showcases their adaptability and effectiveness in managing fluid flow within a wide range of systems.

Role of a Motorized Butterfly Valve in Regulating Flow

Motorized butterfly valves are designed to modulate flow within a pipeline by adjusting the position of a disc to control the passage of fluid. This mechanism allows for precise regulation of flow rates, pressure, and temperature, providing essential control in process systems. The ability to handle large flow capacities with minimal pressure drop makes these valves suitable for a spectrum of applications, from low-pressure HVAC systems to high-pressure industrial processes.

Integration of Motorized Butterfly Valves in Process Control Systems

The seamless integration of motorized butterfly valves into process control systems enhances automation and operational efficiency. By interfacing with control systems, these valves can be remotely monitored and adjusted, enabling real-time response to changes in flow requirements. Automation reduces manual intervention, improves accuracy, and ensures consistent performance, making motorized butterfly valves indispensable components in modern process control setups.

Examples of Industries Utilizing Motorized Butterfly Valves

Numerous industries benefit from the utilization of motorized butterfly valves in their process control systems. Sectors such as water treatment, chemical processing, oil and gas, pharmaceuticals, food and beverage, and HVAC systems rely on these valves for their versatility and dependable flow control. In water treatment plants, for instance, motorized butterfly valves regulate the flow of water and various treatment chemicals with precision, contributing to efficient and reliable operations.

The widespread adoption of motorized valves across diverse industries underscores their significance in facilitating essential fluid handling processes within modern process control systems.

Selection and Sizing of Motorized Butterfly Valves

Factors to Consider When Selecting a Motorized Butterfly Valve

Motorized butterfly valves play a crucial role in the seamless operation of process control systems, and selecting the right valve is paramount to the system’s effectiveness. Factors such as the nature of the fluid, flow characteristics, temperature, pressure, and the application’s specific requirements must be meticulously evaluated. Understanding the chemical and physical properties of the fluid is essential in choosing the appropriate materials for the valve construction to ensure compatibility and prevent corrosion or degradation. Additionally, considering the flow rates, pressure differentials, and bidirectional shutoff capabilities is essential for optimal valve selection.

Sizing Guidelines for Motorized Butterfly Valves in Process Control Systems

Accurate sizing of motorized butterfly valves is imperative to maintain efficient process control. To determine the suitable valve size, factors such as flow rate, pressure drop, and the piping system’s dimensions must be taken into account. Employing sizing guidelines and equations helps in calculating the required valve size to ensure the system operates within the desired parameters. Furthermore, considering the valve’s flow coefficient (Cv), which represents the flow capacity, aids in selecting the appropriate valve size to achieve the desired flow control.

Maintenance and Troubleshooting of Motorized Butterfly Valves

Importance of Regular Maintenance for Motorized Butterfly Valves

Regular maintenance of motorized butterfly valves is crucial for ensuring optimal performance and extending their service life. By conducting routine maintenance, potential issues can be identified and resolved before they escalate, thereby minimizing downtime and costly repairs. Additionally, proper maintenance helps to uphold operational efficiency, prevent leakage, and ensure smooth functioning of the valves within process control systems.

Common Issues and Troubleshooting Techniques for Motorized Butterfly Valves

Common issues that may arise with motorized butterfly valves include leakage, valve sticking, and motor failure. When faced with these challenges, troubleshooting techniques such as inspecting for seal damage, lubricating the valve components, and checking electrical connections can be employed to address the issues effectively. Additionally, conducting a thorough diagnostic assessment of the valve’s components and electrical systems can aid in pinpointing and resolving any operational discrepancies. Regularly scheduled inspections and proactive troubleshooting measures are essential for maintaining the reliability and performance of motorized valves, ultimately contributing to the seamless operation of process control systems.

Conclusion

Motorized butterfly valves play a critical role in process control systems, offering precise flow control and reliable shut-off capabilities. These valves are essential for regulating the flow of liquids, gases, and steam in various industrial applications. With their compact design and efficient operation, motorized butterfly valves are a popular choice for process control systems in industries such as chemical processing, water treatment, HVAC, and more. Their ability to provide accurate flow modulation and quick response to changing process conditions makes them invaluable components in ensuring optimal system performance and safety. Understanding the functionality and benefits of motorized butterfly valves is crucial for engineers and operators seeking to maximize the efficiency and reliability of their process control systems.