Silent Check Valves: Comparing Different Types

Table of Contents

ToggleA Comprehensive Comparison of Silent Check Valves for Municipal Water Distribution Systems

When it comes to municipal water distribution systems, selecting the right type of silent check valve is crucial for efficient operation and long-term cost savings. In this blog post, we will be comparing swing check valves and axial flow silent check valves in terms of their operation and return on investment (ROI). Understanding the differences between these two types of check valves will help industry professionals make informed decisions when it comes to valve selection for municipal water distribution systems.

Understanding Silent Check Valves in Water Systems

What is a Silent Check Valve?

A silent check valve is a type of check valve designed to prevent backflow in a pipeline. Unlike traditional check valves, the silent check valve is specifically engineered to minimize noise and pressure fluctuations, commonly known as water hammer, when the flow direction changes. This is achieved through the incorporation of a spring mechanism that assists in closing the valve before the reversal of fluid flow.

Purpose of Check Valves in Municipal Water Distribution

Check valves play a crucial role in maintaining the efficiency and safety of municipal water distribution systems. Their primary function is to ensure that water flows in a single direction, preventing the backflow of contaminated water into the clean water supply. In the event of a sudden loss of pressure or flow reversal, check valves help maintain the integrity of the water distribution system and prevent potential contamination or damage to the infrastructure.

How Does a Silent Check Valve Work?

The operation of a silent check valve is based on the principle of fluid dynamics and the mechanics of the incorporated spring mechanism. When water flows in the desired direction, the valve remains open, allowing the unrestricted passage of water. However, when there is a reversal in flow, the spring-assisted poppet swiftly closes, preventing backflow and the associated water hammer effect. This design not only ensures efficient flow regulation but also significantly reduces the disruptive effects of water hammer in the system.

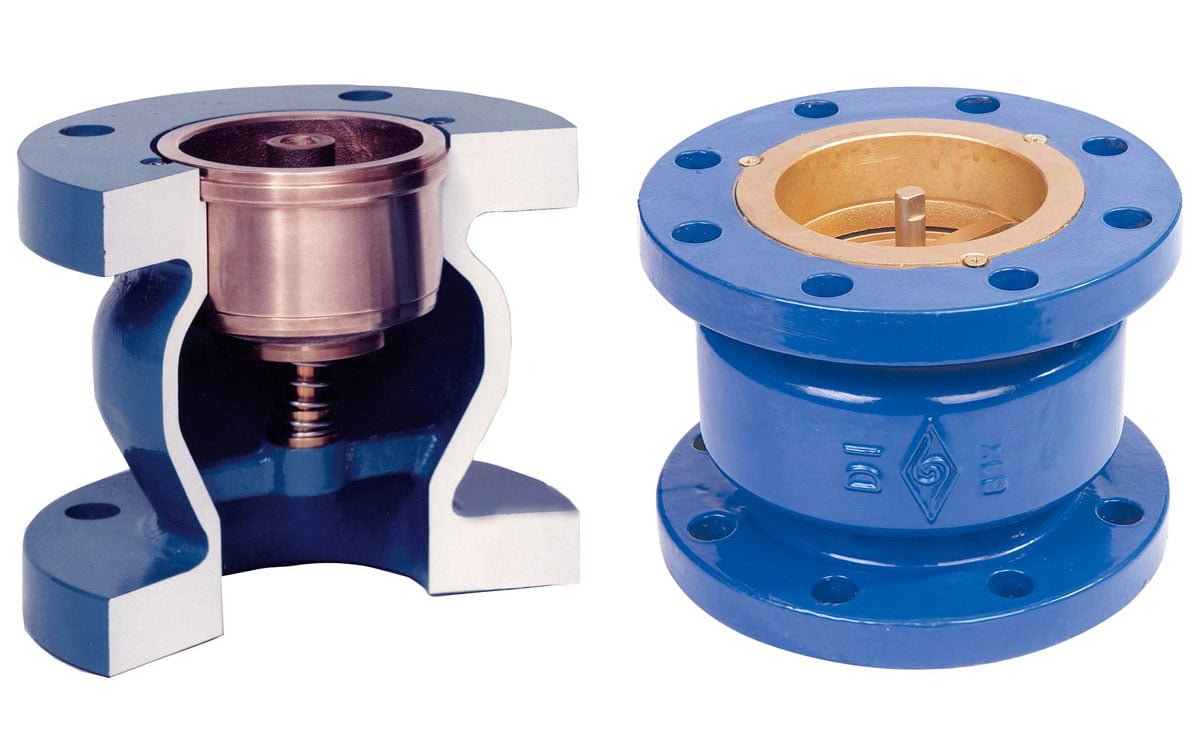

Silent Check Valve Mechanism

The mechanism of a silent check valve involves a carefully engineered interplay of components, including the poppet, spring, and seat. When the flow is in the correct direction, the poppet is held open by the force of the flowing water. In the event of flow reversal, the spring assists in promptly closing the poppet, creating a seal that prevents backflow. This mechanism effectively mitigates water hammer and ensures smooth, uninterrupted operation of the water distribution system.

By understanding the function and mechanism of silent check valves, it becomes evident that these specialized components are essential for maintaining the reliability and performance of municipal water distribution systems.

Types of Silent Check Valves

When it comes to municipal water distribution systems, the selection of the right silent check valve is crucial. Understanding the different types available is essential for making an informed decision. Here, we will explore two common types of silent check valves used in municipal water distribution systems: Swing Check Valves and Axial Flow Silent Check Valves.

Swing Check Valves

Swing check valves are among the most commonly used silent check valves in municipal water distribution systems. They feature a hinged disc that swings open and closed to regulate the flow of water. This design allows for efficient flow control, preventing backflow and water hammer. Swing check valves are known for their reliability and low maintenance requirements, making them a popular choice for a wide range of applications in municipal water systems.

Key features of swing check valves include:

- Efficient Flow Control: The hinged disc design enables smooth regulation of water flow, minimizing pressure fluctuations and surges.

- Reliability: Swing check valves are designed for long-term, trouble-free operation, providing consistent performance in demanding municipal water distribution environments.

- Low Maintenance: With few moving parts and a simple design, swing check valves require minimal maintenance, reducing the total cost of ownership for municipal water systems.

Axial Flow Silent Check Valves

Axial flow silent check valves are specifically designed to minimize water hammer and pressure surges in municipal water distribution systems. Unlike swing check valves, axial flow silent check valves feature a piston that moves along the axial direction of the flow, providing efficient flow regulation and preventing backflow. These valves are well-suited for applications where maintaining steady flow and pressure is critical.

Key features of axial flow silent check valves include:

- Pressure Surge Mitigation: The design of axial flow silent check valves effectively mitigates pressure surges and water hammer, safeguarding the integrity of the municipal water distribution system.

- Steady Flow Regulation: By utilizing axial movement to control flow, these valves ensure a consistent and steady flow of water, minimizing disruptions and optimizing system performance.

- Application Flexibility: Axial flow silent check valves are suitable for a wide range of pipe sizes and pressure classes, offering versatility in municipal water distribution applications.

Understanding the unique characteristics of swing check valves and axial flow silent check valves is essential for selecting the most suitable option for a municipal water distribution system. Each type brings distinct benefits and considerations, ultimately contributing to the overall efficiency and reliability of the water distribution infrastructure.

Pros and Cons of Swing Check Valves

Design and Functionality

Swing check valves, widely used in water and wastewater pumping systems, offer several advantages. They are readily available and relatively low cost, making them an attractive option for municipal water distribution systems. These valves operate automatically, requiring no external power source, and are guided only by the direction of flow. The swing check valve’s design includes a hinged disc that swings open to allow forward flow and automatically closes to prevent reverse flow. This straightforward functionality makes swing check valves easy to install and maintain.

Common Issues with Swing Check Valves

While swing check valves have their benefits, there are also some potential drawbacks to consider. One common issue is the potential for slamming. When the disc swings closed to prevent reverse flow, it can sometimes do so with considerable force, leading to water hammer and associated system damage. Additionally, swing check valves may be prone to leakage and wear over time, especially in applications with high flow rates or frequent operation. Proper sizing and regular maintenance can help mitigate these issues, but it’s important to be aware of these potential challenges when considering swing check valves for municipal water distribution systems.

Advantages of Axial Flow Silent Check Valves

Axial flow silent check valves offer significant advantages compared to swing check valves in municipal water distribution systems. Their design improvements over swing check valves and impact on fluid dynamics make them a preferred choice for critical applications.

Design Improvements Over Swing Check Valves

Axial flow silent check valves employ a spring-loaded disc positioned in the center of the valve, moving axially to enable fluid flow and effectively prevent backflow. This design eliminates the slamming effect typically associated with swing check valves, resulting in quieter and smoother operation. Unlike swing check valves, axial flow silent check valves are specifically engineered to minimize water hammer, a common issue in piping systems that can lead to equipment damage and system failures.

Impact on Fluid Dynamics

The axial flow silent check valves’ unique design significantly impacts fluid dynamics within the municipal water distribution system. By mitigating water hammer and offering quiet, smooth operation, these valves contribute to improved overall system performance. Additionally, the elimination of the characteristic “thump” associated with traditional check valves enhances operational efficiency and reduces stress on the entire system.

Axial flow silent check valves effectively enhance the reliability and performance of municipal water distribution systems, making them a valuable asset in safeguarding against backflow and maintaining optimal fluid dynamics.

Cost Analysis of Valve Types

When it comes to municipal water distribution systems, the cost analysis of different types of silent check valves is a critical aspect of decision-making. Understanding the initial costs, long-term costs, and return on investment (ROI) associated with each valve type is essential for making informed choices.

Initial Costs Comparison

Effective cost management begins with comparing the initial costs of various valve types. Factors such as the purchase price, installation expenses, and any additional components required for deployment should be carefully evaluated. It’s important to consider not only the upfront expenditure but also the cost-effectiveness of the valve in relation to its application. For instance, a higher initial cost for a valve with superior longevity and performance may prove more economical in the long run compared to a cheaper alternative.

Long-Term Costs and ROI

Assessing the long-term costs associated with different valve types involves looking beyond the initial investment. Factors such as maintenance requirements, frequency of repairs, and operational longevity play a significant role in determining the overall cost-effectiveness of a valve. A valve that requires minimal maintenance, has a longer lifespan, and contributes to operational efficiency can yield a higher ROI over time.

Considering the financial implications of valve selection is paramount, as it directly impacts operational expenses and resource allocation for municipal water distribution systems. By examining both the initial costs and long-term ROI of different silent check valve types, municipalities can make informed decisions that align with their budgetary constraints and infrastructure needs.

Performance and Maintenance

A silent check valve’s performance and maintenance are crucial aspects to consider when choosing the right valve for a municipal water distribution system. Understanding the frequency of maintenance requirements, as well as the longevity and durability of the valve, is essential in ensuring the smooth operation of the system while minimizing disruptions.

Frequency of Maintenance Requirements

Silent check valves are designed to operate efficiently with minimal maintenance. The frequency of maintenance largely depends on the valve’s design, the quality of its components, and the operating conditions. In general, modern silent check valves are engineered to require maintenance at longer intervals, reducing the need for frequent inspections and upkeep.

Longevity and Durability

The longevity and durability of a silent check valve are indicative of its overall quality and performance. A high-quality valve is designed to withstand the rigors of continuous operation, offering long-term reliability and minimal downtime. Durable materials, such as stainless steel or corrosion-resistant alloys, contribute to the valve’s ability to endure varying water conditions and maintain consistent performance over an extended period.

In comparison to traditional check valves, silent check valves often exhibit superior longevity and durability, thanks to their advanced design and construction. By investing in a silent check valve with exceptional longevity and durability, municipalities can minimize the need for frequent replacements and reduce overall maintenance costs.

Case Study: Transition from Swing to Axial Flow Valves

Comparative Study Overview

In a diligent effort to enhance the efficiency of municipal water distribution systems, a comparative study was conducted to assess the transition from swing to axial flow valves. The study aimed to evaluate the performance, reliability, and long-term cost-effectiveness of axial flow valves in comparison to traditional swing valves. The study encompassed comprehensive data collection, rigorous testing methodologies, and in-depth analysis to provide valuable insights into the suitability of axial flow valves for modern water distribution networks.

Results and Findings

The comparative study revealed compelling findings that underscore the advantages of transitioning from swing to axial flow valves. The axial flow valves demonstrated superior flow control capabilities, mitigating pressure fluctuations and reducing the risk of water hammer effects. Moreover, the axial flow valves exhibited enhanced resilience to sediment buildup, minimizing the need for frequent maintenance interventions. The study also indicated substantial energy savings and operational cost reductions with the implementation of axial flow valves, contributing to the overall sustainability of municipal water distribution systems.

The empirical evidence gathered from the study portrayed a clear trajectory towards the adoption of axial flow valves, highlighting their potential to revolutionize water distribution infrastructure and optimize system performance. With a keen focus on durability, efficiency, and adaptability, the transition to axial flow valves emerged as a strategic imperative for municipalities striving to elevate the reliability and efficacy of their water distribution networks.

Making the Right Choice for Your System

Factors to Consider When Selecting Check Valves

When selecting check valves for a municipal water distribution system, several factors must be considered to ensure optimal performance and longevity. The following are key considerations:

Flow Rate and Pressure: It is essential to choose check valves that can handle the flow rate and pressure specific to the municipal water system. Understanding the system’s demands is crucial in selecting the appropriate valve to prevent backflow and maintain efficient water distribution.

Material Durability: The material composition of the check valve is pivotal in determining its longevity and resistance to corrosion. Municipal water systems require check valves constructed from durable materials such as stainless steel, ductile iron, or corrosion-resistant alloys to withstand harsh water conditions and ensure long-term functionality.

Maintenance Requirements: Consider the maintenance needs of the check valves. Opt for valves with minimal maintenance requirements to reduce downtime and operational costs for the municipal water system.

Installation Flexibility: Check valves that offer flexible installation options and adaptability to different pipeline configurations can simplify the integration process and accommodate the system’s specific layout.

Compliance with Standards: Ensure that the selected check valves comply with relevant industry standards and regulations to guarantee the safety and reliability of the municipal water distribution system.

Recommendations for Municipal Water Systems

For municipal water systems, the selection of silent check valves, swing check valves, or spring-loaded check valves is crucial to maintaining efficient and reliable water distribution. Based on the aforementioned factors, it is recommended to opt for silent check valves in municipal water systems due to their superior performance in reducing water hammer and preventing backflow. The quiet operation and minimal pressure loss make silent check valves an ideal choice for ensuring uninterrupted water supply while minimizing maintenance requirements. Additionally, selecting check valves from reputable manufacturers known for producing high-quality and reliable products can further enhance the longevity and performance of the municipal water distribution system.

Conclusion

In conclusion, when comparing swing check valves and axial flow silent check valves for municipal water distribution systems, it becomes evident that the latter offers a superior ROI. Despite the initial higher cost of axial flow silent valves, their long-term benefits, including reduced replacement frequency and smoother fluid flow, result in significantly lower overall costs over time. By understanding the importance of long-term value and low cost of ownership, plant managers can make informed decisions that contribute to the efficiency and reliability of water distribution systems.