Globe Valve Maintenance Tips: Longevity and Efficiency

Table of Contents

ToggleGlobe Valve Maintenance

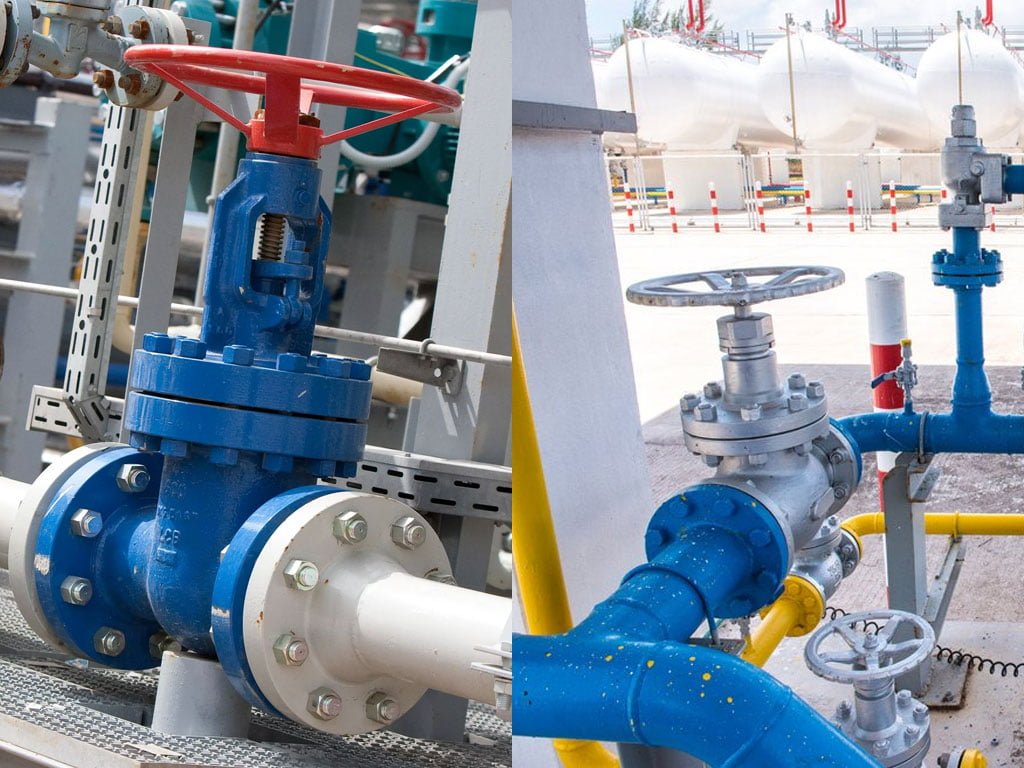

Globe valves play a crucial role in controlling the flow of liquid, making proper maintenance vital. In this article, we’ll cover essential globe valve maintenance tips to ensure the longevity and efficiency of your globe valves. Proper installation and operation, regular inspections, and external and internal maintenance are key to keeping your valves in optimal working condition. By following these globe valve maintenance practices, you can extend the lifespan of your valves and prevent potential issues.

Understanding Globe Valves and Their Importance

Globe valves are essential components in industrial systems, responsible for regulating the flow of fluids. Understanding their functionality and significance is crucial for ensuring the efficiency and longevity of the overall system.

What is a Globe Valve?

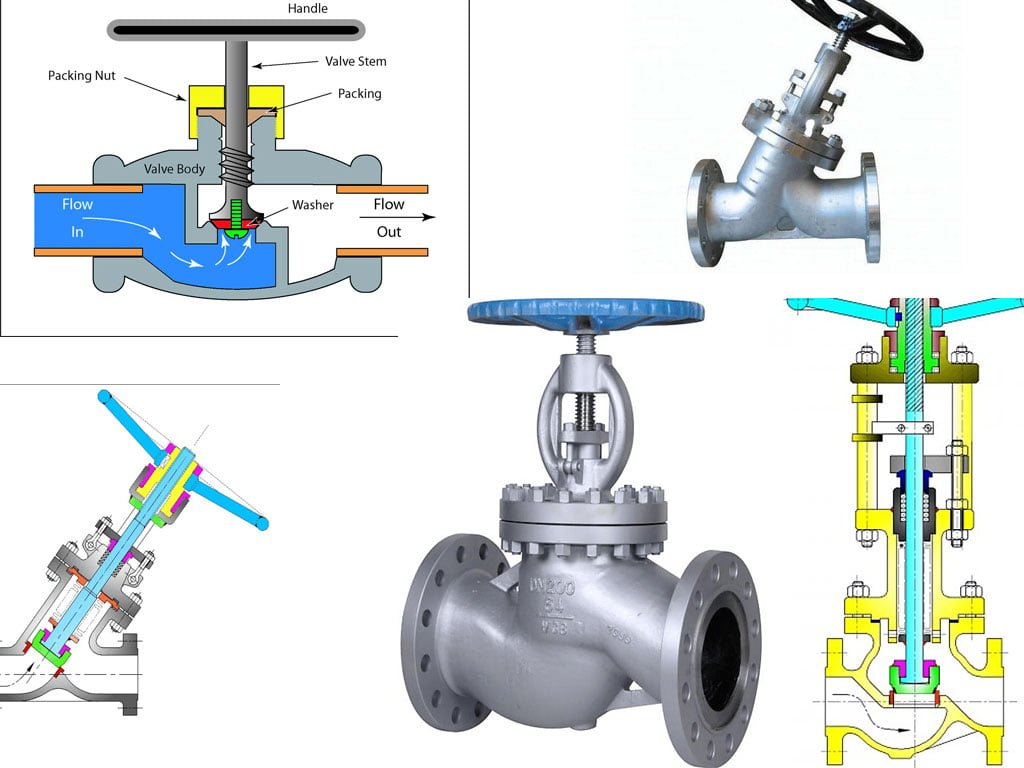

A globe valve is a type of linear motion valve that regulates the flow of a fluid by moving the stem up or down, controlling the flow rate. It is designed with a mechanism that directs the flow of fluid through multiple openings, allowing precise adjustment of the flow.

Key Functions of Globe Valves in Industrial Systems

Flow Regulation: Globe valves provide accurate control over the flow of various types of fluids, including liquids, gases, and steam. Their efficient flow regulation capabilities make them indispensable in industrial settings where precise fluid management is crucial.

Shut-off Mechanism: These valves are proficient in completely stopping the flow of fluids when necessary, contributing to the overall safety and reliability of the system. The ability to shut off the flow helps in preventing leakage and ensuring operational integrity.

Pressure Regulation: Globe valves play a pivotal role in maintaining optimal pressure levels within the system. Their capability to manage pressure variations is vital for the smooth operation of industrial processes, safeguarding equipment and ensuring consistent performance.

Diverse Applications: Due to their versatility, globe valves are extensively used in various industries such as oil and gas, power generation, chemical processing, and water treatment. Their adaptability to different environments and fluid types underscores their importance in industrial applications.

Understanding the fundamental functions and significance of globe valves is essential for implementing effective globe valve maintenance strategies and optimizing their performance within industrial systems.

Regular Inspection Routines for Globe Valve Maintenance

Globe valves are crucial components in various industrial applications. Therefore, proper globe valve maintenance is essential for ensuring longevity and efficiency. Establishing a regular inspection routine is key to identifying and addressing potential issues before they escalate. Here’s a breakdown of the key aspects of a comprehensive inspection routine for globe valves.

Visual Inspections for Globe Valve Maintenance

Visual inspections serve as the initial line of defense in identifying potential issues with globe valves. During visual inspections, look for signs of corrosion, leaks, or any physical damage on the valve body, bonnet, and other components. Pay close attention to the valve stem, seating surfaces, and packing gland for any visible wear or irregularities. Additionally, ensure that the valve is properly aligned and installed to prevent operational issues.

Leak Detection Techniques

Leakage is a common concern with globe valves, and early detection is critical for preventing potential damage and maintaining operational efficiency. Employing leak detection techniques such as ultrasonic testing or applying leak detection solutions can help identify and address leakage issues promptly. Additionally, monitoring the valve during operation for any signs of leakage can provide valuable insights into the valve’s condition and performance.

Assessing Valve Stem Integrity

The integrity of the valve stem is integral to the proper functioning of globe valves. During routine inspections, assess the condition of the valve stem for signs of bending, corrosion, or excessive wear. Check for smooth operation and ensure that the stem packing is effectively sealing to prevent any stem leakage. Proper lubrication of the valve stem is also crucial for maintaining smooth operation and extending the valve’s service life.

By incorporating these comprehensive inspection routines into your maintenance practices, you can proactively identify and address potential issues, thereby ensuring the longevity and optimal performance of globe valves in industrial settings.

Cleaning Procedures in Globe Valve Maintenance

Globe valves are essential for regulating and controlling fluid flow in various industrial applications. To ensure their longevity and efficiency, it is essential to implement regular cleaning procedures. Clean valve components are vital for optimal performance and to prevent the accumulation of debris that can potentially affect the functionality of the valve. Let’s delve into the importance of clean valve components, a step-by-step guide to cleaning a globe valve, and the significance of choosing the right cleaning agents. Cleaning is an important part of globe valve maintenance.

The Importance of Clean Valve Components

Maintaining clean valve components is imperative for the smooth operation of globe valves. Accumulated debris and contaminants can lead to blockages and hinder the proper functioning of the valve. Additionally, clean components contribute to the prevention of corrosion and wear, thereby extending the lifespan of the globe valve. By ensuring that the valve components remain free from impurities, you can effectively minimize the risk of operational disruptions and costly repairs.

Step-by-Step Guide to Cleaning – Globe Valve Maintenance

Preparation: Begin by shutting off the valve and relieving any pressure in the system. This is essential to ensure safety during the cleaning process.

Disassembly: Carefully disassemble the globe valve, paying close attention to the arrangement of components to facilitate reassembly. Inspect each part for signs of wear or damage.

Cleaning: Utilize a suitable cleaning agent and a soft brush to gently remove any built-up debris and contaminants from the valve components. Ensure thorough cleaning of each part to eliminate any potential sources of obstruction.

Inspection: After cleaning, inspect all components for any remaining impurities or signs of deterioration. This meticulous examination is crucial for identifying any issues that may compromise the valve’s performance.

Reassembly: Once all components are thoroughly cleaned and inspected, carefully reassemble the globe valve, ensuring that each part is securely fitted in its respective position.

Testing: Conduct a comprehensive testing procedure to verify the valve’s functionality and assess the effectiveness of the cleaning process.

Choosing the Right Cleaning Agents

Selecting the appropriate cleaning agents is paramount to safeguarding the integrity of the globe valve components. Consider the material composition of the valve and the nature of contaminants present when choosing cleaning agents. Mild solvents or specific cleaning solutions recommended by manufacturers can aid in maintaining the cleanliness of valve components without causing damage or corrosion.

Regular cleaning and maintenance of globe valves are essential to uphold their operational efficiency and longevity. By understanding the significance of clean valve components, following a structured cleaning process, and utilizing suitable cleaning agents, you can effectively preserve the performance and durability of globe valves in diverse industrial settings.

Lubrication: Key to Smooth Operation

Maintaining proper lubrication for globe valves is crucial to ensuring their smooth and efficient operation. Lubrication helps to minimize friction, reduce wear and tear, and prevent corrosion, ultimately prolonging the lifespan of the valves and minimizing the need for repairs. In this section, we will discuss the essential aspects of lubricating globe valves to maintain their longevity and efficiency.

Identifying Lubrication Points on a Globe Valve

Before initiating the lubrication process, it is essential to identify the specific points on the globe valve that require lubrication. These typically include the valve stem, packing gland, and any other areas where metal components come into contact during the valve’s operation. Proper identification of these lubrication points is crucial to ensure thorough and effective application of lubricants.

Selecting the Correct Lubricant

Choosing the appropriate lubricant is paramount to the effective functioning of globe valves. The selected lubricant should be compatible with the materials used in the valve assembly and should offer high performance in terms of temperature resilience, viscosity, and chemical resistance. It is recommended to refer to the valve manufacturer’s guidelines or consult with a lubrication expert to determine the most suitable lubricant for the specific globe valve application.

Scheduling Lubrication for Globe Valve Maintenance

Establishing a regular lubrication maintenance schedule is imperative for the optimal performance and longevity of globe valves. The frequency of lubrication will depend on various factors such as the operating environment, valve usage frequency, and the type of lubricant employed. It is advisable to create a comprehensive globe valve maintenance plan that outlines the specific intervals for lubrication, inspection, and reapplication of lubricants as needed. Adhering to a consistent lubrication schedule can significantly contribute to the efficiency and durability of globe valves.

By adequately identifying lubrication points, selecting the correct lubricant, and scheduling routine maintenance, globe valve operators can effectively uphold the smooth operation and longevity of these essential components within their industrial systems.

The Role of Gaskets and Packing in Globe Valves

Inspecting Gasket and Packing Material

To ensure the longevity and efficiency of globe valves, inspecting gasket and packing material is crucial. Gaskets and packing play a pivotal role in preventing leaks and maintaining the integrity of the valve. During inspection, check for signs of wear, tear, or deterioration in the gasket and packing material. Look for any discoloration, cracks, or deformation that could compromise the sealing quality.

When to Replace Gaskets and Packing During Globe Valve Maintenance

Knowing when to replace gaskets and packing is essential for optimal valve performance. If the gaskets show signs of compression set or loss of elasticity, or if the packing material exhibits excessive extrusion or leakage, it’s time for replacement. Additionally, any damage or degradation observed during inspection is a clear indication that the gaskets and packing need to be replaced to avoid potential leaks and operational issues.

Proper Installation Techniques for Gaskets and Packing

When installing new gaskets and packing, it’s important to follow proper techniques to ensure effective sealing and functionality. Clean the sealing surfaces thoroughly to remove any residue or foreign particles. Employ the correct tightening torque to achieve the desired compression and sealing without overloading the gasket. Utilize appropriate tools and equipment to prevent damage to the gaskets and packing during installation, ensuring a secure and reliable seal.

By meticulously inspecting, timely replacing, and properly installing gaskets and packing, the longevity and efficiency of globe valves can be upheld, minimizing the risk of leaks and maximizing operational reliability.

Preventative Globe Valve Maintenance Strategies

Preventative maintenance plays a crucial role in the longevity and efficiency of globe valves. By implementing effective strategies, you can minimize unplanned downtime and ensure the smooth operation of your equipment. Here are key preventative maintenance strategies to consider:

Creating a Glove Valve Maintenance Schedule

Developing a comprehensive globe valve maintenance schedule is essential for ensuring that all valves receive timely attention. This involves organizing and prioritizing maintenance tasks to maximize the lifespan and performance of the valves. Utilizing preventive maintenance software can help streamline and manage these schedules effectively.

Understanding Wear Patterns in Globe Valves

Analyzing wear patterns in globe valves is vital for identifying potential issues and determining the most effective maintenance approaches. By understanding how wear occurs within the valves, maintenance teams can proactively address areas prone to deterioration and implement targeted maintenance interventions.

Benefits of Predictive Globe Valve Maintenance

Incorporating predictive globe valve maintenance approaches, such as real-time data insights and condition monitoring, offers significant advantages for valve and pipeline systems. By leveraging predictive techniques, maintenance teams can anticipate potential failures, schedule maintenance activities based on actual performance data, and ultimately optimize the efficiency and reliability of globe valves.

Implementing these preventative globe valve maintenance strategies can significantly contribute to the sustained performance and extended lifespan of the valves, ultimately reducing operational disruptions and minimizing repair costs.

Troubleshooting Common Globe Valve Issues

Globe valves are crucial components of fluid control systems, and any malfunction can lead to disruptions and inefficiencies. Identifying and addressing common globe valve problems is essential to maintaining smooth operations and preventing system damage.

Identifying Causes of Valve Failure

Valve failures can stem from various issues such as leakage, reduced flow, and difficulty in operation. These problems may result from wear and tear, corrosion, or improper installation. By conducting thorough inspections, you can pinpoint the root causes of valve failure, which may include damaged valve seats, worn-out packing, or stem misalignment.

Steps to Resolve Minor Valve Problems

Minor valve issues, such as leaks and sticking, can often be resolved through simple maintenance tasks. This may involve tightening packing glands, lubricating the stem, or replacing damaged seals. Regular cleaning and lubrication can prevent minor issues from escalating into major failures.

When to Seek Professional Repairs for Globe Valve Maintenance

In some cases, globe valve problems may require professional attention. If you encounter persistent leaks, excessive corrosion, or significant operational issues, it is advisable to engage the expertise of qualified valve technicians. Professional repairs may involve thorough valve disassembly, parts replacement, and precision adjustments to restore optimal performance.

By promptly addressing valve issues and engaging in proactive globe valve maintenance, you can ensure the longevity and efficiency of your valves, contributing to the smooth operation of your fluid control systems.

Documentation of Globe Valve Maintenance

Maintaining detailed maintenance logs for globe valves is a critical aspect of ensuring their longevity and efficiency. Tracking valve performance over time and utilizing maintenance records for regulatory compliance can significantly contribute to the smooth operation of globe valves in industrial settings.

Importance of Detailed Globe Valve Maintenance Logs

Keeping comprehensive maintenance logs for each globe valve is essential for identifying patterns and trends in valve performance. These records should include details such as date of maintenance, type of maintenance performed, any issues identified, and parts replaced. By documenting these details, vallve maintenance teams can gain valuable insights into the overall condition of the valves and make informed decisions about future maintenance needs.

Tracking Valve Performance Over Time

Regularly updating globe valve maintenance logs allows for the tracking of valve performance over time. By analyzing historical maintenance data, maintenance teams can identify any recurring issues or declining performance trends. This proactive approach enables them to address potential problems before they escalate, thereby extending the lifespan of the globe valves and minimizing unplanned downtime.

Utilizing Maintenance Records for Regulatory Compliance

In many industrial sectors, compliance with regulatory standards is a non-negotiable requirement. Detailed globe valve maintenance logs serve as valuable documentation to demonstrate that the valves are being properly maintained in accordance with industry regulations. By maintaining accurate records of maintenance activities, businesses can easily provide the necessary proof of compliance during inspections or audits, avoiding potential penalties and ensuring operational continuity.

Conclusion

In conclusion, proper globe valve maintenance is crucial for ensuring the longevity and efficiency of the overall system. Starting with correct installation and operation, regular inspections, and external and internal maintenance can significantly extend the lifespan of these essential components. By following these maintenance tips, you can minimize wear and tear, prevent potential failures, and optimize the performance of your globe valves for years to come.