Usage of Ball Valves in Industrial Systems

Table of Contents

ToggleIntroduction to Ball Valves

Ball valves are widely used in industrial applications for controlling the flow of liquids and gases. These valves are designed with a spherical disc to regulate the flow, making them suitable for a range of high-pressure and high-temperature environments. Understanding the specific uses and advantages of a ball valve is crucial for various industries, ranging from oil and gas to manufacturing and beyond.

Understanding Ball Valves

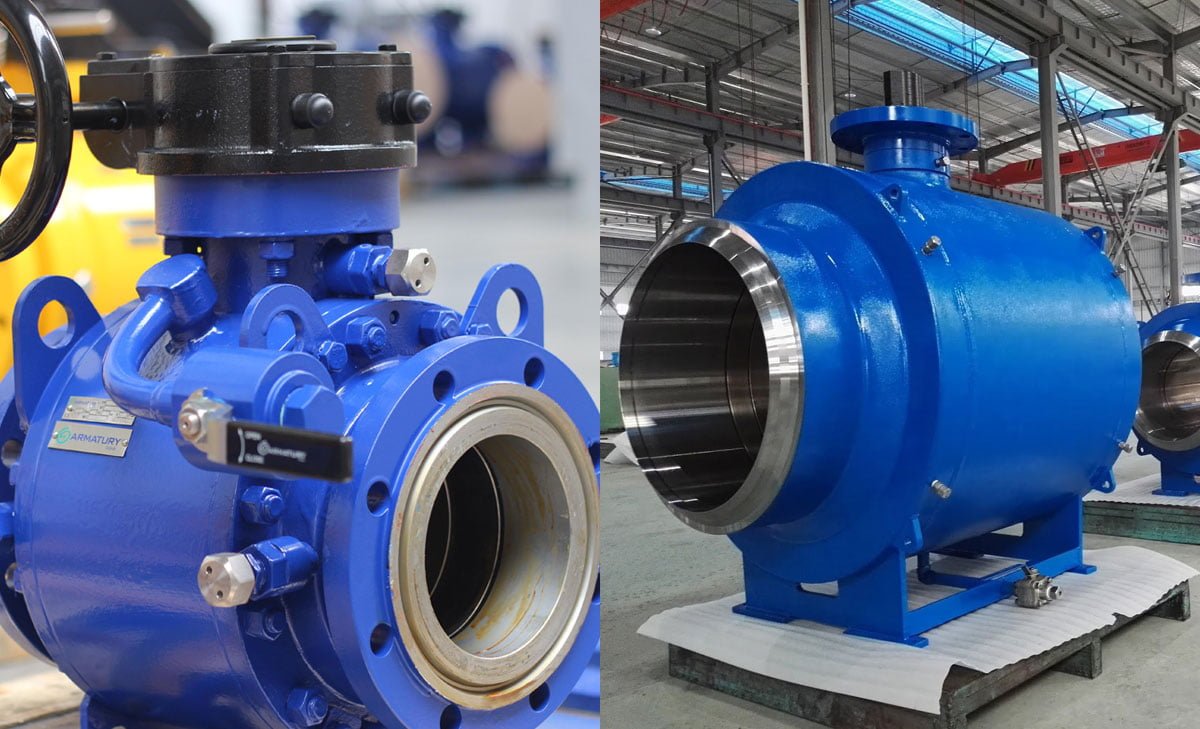

A ball valve is a shut-off valve used to control the flow of liquids or gases through a rotary ball with a bore. Its quarter-turn (90-degree) rotation around its axis either allows the medium to flow through or blocks it. They are known for their extended service life and reliable sealing, making them more popular as shut-off valves than gate valves. They are also more resistant to contaminated media than most other valve types.

Basic Design and Operation

The typical design of a ball valve includes the housing, seats, ball, and a lever for ball rotation. These valves can have two, three, or four ports, and they can be threaded or a combination of female and male threaded. A threaded ball valve comes in various types, including mini ball valves, angled ball valves, ISO-top ball valves, those with integrated strainers, and more. It offers a wide range of options and operate across a large pressure and temperature range.

Types of Ball Valves

Ball valves come in different types to suit various applications. These could include standard threaded ball valves, automatic ball valves, electric ball valves, and pneumatic ball valves. Each type is designed to serve specific purposes, such as controlling different media or meeting particular operating conditions.

Is Ball Valve a Gate Valve?

A ball valve is not the same as a gate valve. A ball valve uses a pivoting ball to control the flow of fluid, while a gate valve uses a sliding gate. A ball valve is typically better for on/off control, while a gate valve is more suitable for controlling the flow of fluid. Both valves have distinct features and applications, so it’s important to choose the right valve for specific needs and requirements in a given system.

Is Ball Valve a Control Valve?

A ball valve is not typically considered a control valve. While it can be used to control the flow of liquids or gases, it does not offer the precision and modulation capabilities that are generally associated with control valves. Control valves, such as the globe valve, are specifically designed to regulate the flow of fluid with a high level of accuracy and control, often used in industrial processes where precise control of flow, pressure, and temperature is critical. A Ball valve on the other hand, is often used in applications where the flow needs to be fully on or off, rather than finely controlled.

Industrial Applications of Ball Valves

They are crucial components in various industrial processes due to their reliable performance and durability. These valves are widely used in the oil and gas industry, water treatment plants, chemical processing, and HVAC systems.

Oil and Gas Industry

In the oil and gas industry, they play a critical role in controlling the flow of fluids and gases in pipelines and storage tanks. Their ability to handle high pressures and temperatures makes them ideal for upstream, midstream, and downstream applications. Whether it’s isolation, flow control, or emergency shut-off, ball valves are essential for maintaining operational efficiency and safety in the oil and gas sector.

Water Treatment Plants

Ball valves are extensively employed in water treatment plants for regulating the flow of water and various chemicals used in the treatment process. Their corrosion-resistant properties and tight sealing capabilities make them suitable for handling different types of liquids and gases, ensuring smooth and efficient operation of water treatment facilities.

Chemical Processing

In the chemical processing industry, where the handling of corrosive and hazardous chemicals is common, they are preferred for their resistance to chemical corrosion and their ability to maintain a tight seal even after prolonged exposure to aggressive substances. These valves provide precise flow control, helping to optimize production processes while ensuring safety and reliability.

HVAC Systems

Ball valves are integral to HVAC (heating, ventilation, and air conditioning) systems, where they are used to regulate the flow of water, air, and refrigerants. With their quick and precise operation, these valves enable efficient temperature control and fluid distribution in commercial and residential HVAC applications, contributing to energy savings and indoor comfort.

Residential and Commercial Uses of Ball Valves

Ball valves are commonly used in both residential and commercial settings due to their versatility and reliability. They serve various purposes in plumbing systems, gas supply lines, and irrigation systems.

Plumbing Systems

In residential and commercial plumbing systems, these valves play a crucial role in regulating the flow of water. Whether it’s controlling the water supply to a specific area or shutting off the water in case of repairs or emergencies, a ball valve provides a convenient and efficient solution. It’s quick 90-degree turn operation allows for swift on/off control, making it ideal for plumbing applications where immediate shut-off is necessary.

Gas Supply Lines

Ball valves are also essential components in gas supply lines, ensuring the safe and reliable control of gas flow. Whether it’s for residential heating systems or commercial industrial applications, ball valves offer a secure shut-off mechanism to prevent gas leaks and ensure optimal safety. Their durable construction and tight seal make them suitable for handling various types of gases with precision and confidence.

Irrigation Systems

In irrigation systems for both residential gardens and commercial landscapes, these valves are used to regulate the flow of water to different zones. Their ability to handle high pressures and corrosive environments makes them an ideal choice for controlling water distribution in diverse irrigation setups. With the capability to withstand varying temperatures and operating conditions, ball valves provide efficient water management for maintaining lush greenery and agricultural productivity.

By serving critical functions in plumbing, gas supply, and irrigation systems, these valves prove to be indispensable in both residential and commercial settings, ensuring seamless control and reliable operation across diverse applications.

Ball Valve Materials and Selection

When it comes to ball valve materials, the selection plays a crucial role in determining the valve’s performance, durability, and suitability for specific applications. Three common materials for ball valves are stainless steel, brass, and PVC.

Stainless Steel Ball Valves

Stainless steel ball valves are known for their exceptional corrosion resistance and strength, making them suitable for demanding industrial applications. Their durability and ability to withstand high temperatures and pressures make them a popular choice for applications in chemical processing, oil and gas, and food and beverage industries. The smooth surface finish of stainless steel also promotes reliable operation and minimal friction, ensuring a longer service life.

Brass Ball Valves

Brass ball valves are valued for their economic benefits and versatility in various applications. They offer good corrosion resistance, making them suitable for water, air, and gas applications. They are often chosen for residential and commercial plumbing systems, irrigation, and general utility services. However, they may not be suitable for applications involving high temperatures or aggressive chemicals due to their lower resistance compared to stainless steel.

PVC Ball Valves

PVC ball valves are lightweight, cost-effective, and resistant to corrosion and chemical attack, particularly from acids and alkalis. They are commonly used in water treatment, chemical processing, and irrigation systems. Their non-conductive nature and ability to withstand high-pressure applications make them an ideal choice for various industrial and agricultural uses. However, PVC ball valves may not be suitable for applications involving high temperatures as they have a lower temperature tolerance compared to stainless steel or brass.

Understanding the characteristics and advantages of each material is essential in determining the most suitable ball valve for specific applications, ensuring optimal performance and longevity.

The Advantages of Ball Valves

Ball valves are essential components in many industries due to their reliability and efficiency. Understanding the advantages of this valve can help businesses make informed decisions about it’s use. Here are several key advantages of ball valves:

- Excellent Shut-Off Functionality: A Ball valve offers excellent sealing capabilities, providing a reliable shut-off for applications requiring tight sealing to prevent leakage.

- Durability: A ball valves is highly durable and can withstand high pressures and temperatures, making it suitable for a wide range of industrial applications.

- Low Maintenance: Compared to other types of valves, a ball valve requires minimal maintenance, reducing downtime and operational costs for businesses.

- Quick Operation: These valves can be quickly and easily operated, allowing for efficient control of flow and minimal time for opening and closing.

- Versatility: Ball valves can handle a variety of fluids, including corrosive and abrasive media, making them versatile for different industrial processes.

- Compact Design: The compact design of ball valves makes them ideal for applications with limited space, contributing to efficient system layout and installation.

- Bi-Directional Flow: Ball valves can facilitate bi-directional flow, allowing for flexibility in system design and operation.

- Corrosion Resistance: Many ball valves are constructed from materials that offer excellent corrosion resistance, ensuring longevity and reliability in harsh environments.

- Cost-Effective: With their long lifespan, low maintenance requirements, and efficient operation, ball valves offer a cost-effective solution for fluid control needs.

In conclusion, the advantages of ball valves make them a preferred choice in various industries, providing reliable performance, durability, and cost-effectiveness for fluid control applications. Understanding these benefits can help businesses make informed decisions about integrating these valves into their systems.

Maintenance and Safety Considerations

Regular maintenance of ball valves is crucial to ensure their proper functioning and longevity. By following some key tips, you can keep your ball valves in optimal condition and minimize the risk of malfunctions.

Regular Maintenance Tips

- Visual Inspection: Regularly inspect the ball valve for any signs of leakage, corrosion, or damage. Look for wear and tear on the seals, seats, and valve body to catch any issues early on.

- Lubrication: Proper lubrication is essential to ensure smooth operation of the ball valve. Apply lubricant to the stem and ball to prevent friction and maintain easy movement.

- Operational Testing: Periodically open and close the valve to check for smooth operation and to prevent sticking or jamming due to debris or corrosion buildup.

- Cleaning: Keep the valve and surrounding area clean to prevent debris from entering the valve and causing damage.

Safety Precautions

- Pressurized Systems: Always depressurize the system before performing any maintenance procedures on the ball valve to prevent accidents and injuries.

- Proper Tools: Use appropriate tools and equipment when working on the valve to ensure safety and prevent damage to the valve components.

- Safety Gear: Wear protective gear such as gloves and goggles to safeguard against potential hazards during maintenance tasks.

- Training: Ensure that personnel performing maintenance on ball valves are properly trained in safety protocols and procedures to prevent accidents and injuries.

Following these maintenance tips and safety precautions will not only extend the lifespan of ball valves but also contribute to a safer working environment.

Innovations in Ball Valve Technology

Smart Ball Valves

In recent years, the integration of smart technology into ball valves has significantly enhanced their functionality and efficiency. Smart ball valves are equipped with sensors and actuators that enable automated operation and remote monitoring, optimizing control and performance. These valves can be seamlessly integrated into advanced control systems, allowing for precise regulation of flow and pressure. Furthermore, the implementation of smart technology facilitates real-time data collection and analysis, enabling predictive maintenance and proactive decision-making.

Improvements in Material Science

Advancements in material science have revolutionized the design and construction of ball valves, leading to enhanced durability and performance. The utilization of high-quality alloys and composites has resulted in ball valves with superior corrosion resistance and mechanical strength, extending their operational lifespan and reliability. Additionally, innovative surface treatments and coatings have been developed to mitigate wear and tear, ensuring sustained functionality even in demanding industrial environments. These material advancements have elevated the capabilities of ball valves, making them well-suited for a diverse range of applications.

Conclusion

In conclusion, ball valves are crucial components in various industries for controlling the flow of liquids and gases. Their ability to provide reliable shutoff makes them ideal for applications where tight sealing is necessary. The versatility and durability of ball valves make them suitable for a wide range of processes, including in the oil and gas, pharmaceutical, and chemical industries. Understanding the specific requirements of a system is essential in selecting the right type of ball valve to ensure optimal performance and safety.