The Role of Ball Valves in Water Systems

Table of Contents

ToggleIntroduction

When it comes to controlling the flow of water in a plumbing system, ball valves play a crucial role. These valves are designed to provide a reliable shut-off and are commonly used in residential, commercial, and industrial applications. In this blog post, we will explore the functionality and benefits of ball valves for water, as well as their key features and considerations for installation. Understanding the importance of selecting the right ball valve for water applications is essential for ensuring efficient and effective plumbing systems.

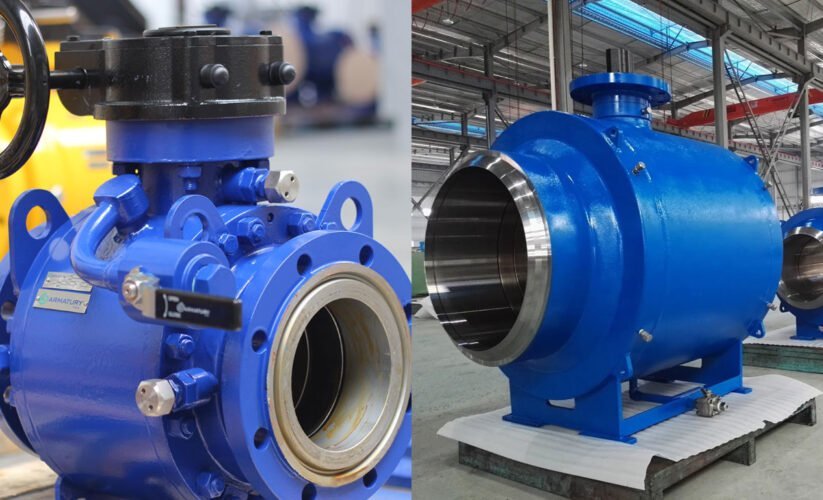

Understanding Ball Valves and Their Role in Water Systems

Ball valves are essential components in water systems, providing reliable control of the flow. Understanding their design and operation is crucial for efficient water management.

The Basic Design of a Ball Valve

A ball valve consists of a hollow, perforated, and pivoting ball that controls the flow of water. The ball has a port, known as the bore, through the center. When the bore is aligned with the inlet and outlet, it allows water to flow. Rotating the ball 90 degrees using the lever or handle perpendicular to the flow results in the bore being closed off, halting the water supply.

How Ball Valves Operate

Ball valves operate using a quarter turn mechanism, providing quick and easy control of water flow. When the handle is parallel to the pipe, the valve is open, allowing water to pass through. Conversely, when the handle is perpendicular to the pipe, the valve is closed, preventing the flow of water. This simplicity in operation makes ball valves highly convenient for various applications in water systems.

Understanding the basic design and operation of ball valves is essential to grasp their role in water systems and the significance of utilizing them for efficient water flow management.

Types of Ball Valves for Water Applications

Full Port Ball Valves for Maximum Flow

Full port ball valves are designed to allow maximum flow of water through the valve. They feature a larger ball and a bore, ensuring minimal friction loss. This design enables unrestricted flow, making full port ball valves an ideal choice for applications where maximum flow is required, such as in industrial settings or large-scale water distribution systems.

Reduced Port Ball Valves for Control

Reduced port ball valves, as the name suggests, have a smaller ball and bore compared to full port valves. These valves are utilized when precise control over the flow of water is needed. By allowing for moderate flow, reduced port ball valves are commonly used in residential and commercial settings, as well as in irrigation systems, where flow control is essential for efficient water management.

Multi-Turn Ball Valves for Fine Adjustments

Multi-turn ball valves are designed to provide fine adjustments in the flow of water. The operation of these valves involves multiple rotations of the stem to open or close the valve. This mechanism allows for precise regulation of water flow, making multi-turn ball valves suitable for applications that demand meticulous adjustments, such as laboratory equipment, water treatment facilities, and other systems where refined flow control is critical.

By understanding the distinct characteristics and functionalities of these types of ball valves, it becomes easier to select the most suitable option for specific water application needs.

Material Choices for Ball Valves in Water Systems

A crucial aspect of selecting the right ball valve for your water system is understanding the different material options available. Each material offers unique properties that make it suitable for specific applications. Here are three common material choices for ball valves in water systems:

Stainless Steel Ball Valves for Durability

Stainless steel ball valves are highly durable and resistant to corrosion, making them ideal for demanding water system environments. They are capable of withstanding high temperatures and pressures, ensuring long-term reliability. Additionally, stainless steel ball valves require minimal maintenance, offering a cost-effective solution over the valve’s lifespan.

Brass Ball Valves for Cost-Effectiveness

Brass ball valves are known for their cost-effectiveness and versatility in water systems. They provide excellent durability and are less susceptible to corrosion compared to other materials. Brass ball valves are relatively lightweight and easy to install, making them a popular choice for residential and commercial water applications where cost efficiency is a priority.

PVC Ball Valves for Corrosion Resistance

PVC ball valves are prized for their exceptional corrosion resistance, making them well-suited for water systems where exposure to corrosive elements is a concern. These valves are lightweight, easy to install, and offer excellent chemical resistance. PVC ball valves are an excellent choice for applications where avoiding metal contamination is essential and where cost-effective corrosion resistance is required.

Advantages of Using Ball Valves in Water Systems

Ball valves are highly advantageous for water systems due to their reliability, ease of maintenance, and quick shutoff features.

Reliability and Longevity

Ball valves are renowned for their exceptional shut-off capability, ensuring a tight seal that prevents leakage. Their spherical closure design enables reliable and secure shutoff, making them ideal for high-pressure systems. This reliability contributes to their longevity, minimizing the need for frequent maintenance and replacement.

Ease of Maintenance and Repair

One of the key advantages of a ball valve in water systems is it’s ease of maintenance and repair. It’s simple design allows for quick and straightforward operation, reducing downtime for maintenance tasks. With minimal components and accessible internals, maintenance and repairs can be efficiently conducted, minimizing disruption to the water system.

Quick Shutoff Features for Emergencies

In water systems, the ability to quickly shut off the flow of water is crucial, especially in emergency situations. Ball valves excel in this aspect, offering quick and easy operation with a quarter turn of the handle or lever. This rapid shutoff capability helps mitigate potential water-related emergencies, allowing for swift intervention and control of the water flow.

As an example, think of a ball valve as a reliable sentry guarding the water system, standing ready to swiftly shut off the flow at a moment’s notice. Its design allows for easy maintenance, akin to a well-oiled machine that can be swiftly fine-tuned to ensure seamless operation. In the event of an emergency, the ball valve acts as a steadfast protector, promptly responding to halt the flow of water, averting potential crises.

Installation Tips for Ball Valves in Water Systems

Proper Sizing and Fit for Your Piping

When installing ball valves in water systems, it is crucial to ensure proper sizing and fit for the piping. The valve should match the diameter of the pipe to avoid any obstructions or disruptions in the water flow. Proper sizing and fit prevent leaks and ensure efficient operation of the system. Carefully measure the pipe diameter and select a ball valve that corresponds to the size of the piping to achieve a seamless fit.

The Importance of Using the Right Tools and Sealants

Using the right tools and sealants is essential for the successful installation of ball valves in water systems. It is crucial to use tools specifically designed for working with ball valves to avoid damaging the components. Additionally, selecting the appropriate sealants designed for water systems is vital to prevent leaks and ensure a secure seal. Utilizing the right tools and sealants guarantees the longevity and reliability of the ball valve installation.

Testing for Leaks After Installation

After the ball valve is installed in the water system, it is imperative to conduct thorough testing for leaks. This involves pressurizing the system and inspecting the valve and its connections for any signs of leakage. Performing this test ensures that the installation was executed accurately and that the valve is functioning as intended. By conducting a comprehensive leak test, any potential issues can be identified and addressed, ensuring the integrity of the water system.

Common Issues and Troubleshooting Ball Valves

Ball valves are crucial components in water systems, but they can encounter various issues that require troubleshooting. Understanding and addressing common problems can help maintain the efficient operation of ball valves, ensuring smooth water flow and preventing water wastage.

Dealing with Water Pressure Problems

Water pressure issues can affect the performance of ball valves. If you notice a drop in water pressure, it could indicate a blockage within the valve. To troubleshoot this, start by checking the inlet and outlet of the valve for any debris or mineral buildup. Clearing these obstructions can help restore normal water pressure.

Another potential cause of water pressure problems is a faulty pressure regulator or a clogged inlet pipe. Inspect these components and replace or clean them as necessary to ensure optimal water pressure for the ball valve.

Addressing Leaks and Seal Failures

Leakage around the ball valve can be a sign of seal failures or damage to the valve components. To address this issue, start by inspecting the seals for wear and tear. If the seals are damaged, replacing them with new ones can resolve the leakage problem.

In some cases, tightening the connections around the ball valve may also effectively stop minor leaks. However, if the leaks persist, it may be necessary to replace the valve or seek professional assistance to identify and rectify the underlying cause of the seal failures.

Steps to Take When a Ball Valve is Stuck

A stuck ball valve can hinder the flow of water and disrupt the functioning of the water system. When encountering a stuck ball valve, it is essential to take precise steps to resolve the issue without causing further damage to the valve or the surrounding components.

Start by gently applying lubricant to the affected areas of the valve to reduce friction and facilitate movement. Allow the lubricant to penetrate the internal components before attempting to operate the valve again.

If the valve remains stuck, it may require disassembly to identify and address the root cause of the obstruction. Carefully disassemble the valve, inspect each component for any obstructions or damage, and clean or replace the affected parts as needed to restore the smooth operation of the ball valve.

Regulatory Standards and Certifications for Water Ball Valves

Ensuring compliance with regulatory standards and certifications is crucial when selecting ball valves for water systems. Understanding the significance of NSF/ANSI standards and lead-free certifications is essential to guarantee the safety and reliability of water ball valves.

Understanding NSF/ANSI Standards

The NSF/ANSI standards outline the requirements for materials, design, construction, and performance of products that come into contact with drinking water. When choosing water ball valves, it is imperative to look for NSF/ANSI 61 and NSF/ANSI 372 certifications. NSF/ANSI 61 certification ensures that the valve materials do not leach harmful contaminants into the water, while NSF/ANSI 372 certification verifies that the valves are lead-free, meeting the strict lead content requirements.

The Significance of Lead-Free Certifications

Lead contamination in water can have severe health implications, making lead-free certifications vital for water ball valves. The “lead-free” designation guarantees that the valves comply with the reduction of lead in drinking water act, ensuring minimal lead content to safeguard against potential lead exposure. Look for reputable certifications such as NSF/ANSI 372 to confirm that the valves are indeed lead-free, providing peace of mind regarding water quality and safety.

Future and Innovations in Ball Valve Technology

The future of ball valve technology is rapidly evolving, with a focus on smart ball valves and automation to enhance operational efficiency and control. These advanced valves are equipped with sensors and actuators, allowing for remote monitoring and automated adjustments. Smart ball valves can be integrated into sophisticated control systems, providing real-time data and enabling predictive maintenance to minimize downtime and optimize performance.

Smart Ball Valves and Automation

Smart ball valves are designed to streamline operations by enabling remote control and automation. They can be programmed to respond to specific conditions, such as changes in flow or pressure, contributing to improved reliability and process optimization. Moreover, the integration of smart ball valves into Industrial Internet of Things (IIoT) platforms facilitates data-driven decision-making, predictive maintenance, and enhanced safety protocols. These advancements herald a new era of enhanced productivity and cost savings in various industrial applications.

Eco-Friendly Materials and Manufacturing Processes

Innovations in ball valve technology also encompass the use of eco-friendly materials and manufacturing processes. With a growing emphasis on sustainability, manufacturers are exploring alternatives to traditional materials, such as lead-free brass and corrosion-resistant polymers. These eco-friendly materials not only comply with stringent regulations but also contribute to environmental conservation efforts.

Furthermore, advancements in manufacturing processes, such as additive manufacturing and precision engineering, are enhancing the efficiency and sustainability of ball valve production. These technologies reduce material waste, energy consumption, and emissions while enabling the creation of complex designs and customized solutions. By embracing eco-friendly materials and manufacturing processes, the ball valve industry is aligning with global sustainability goals and paving the way for a greener, more responsible future.

The future and innovations in ball valve technology demonstrate a commitment to harnessing cutting-edge advancements for enhanced performance, sustainability, and operational excellence. From smart automation to eco-friendly materials, these advancements are shaping the next generation of ball valves, offering unprecedented capabilities and environmental responsibility.

Conclusion

In conclusion, ball valves are essential components for water systems, offering precise control and reliable shut-off. These valves are durable, versatile, and suitable for a wide range of applications, making them a practical choice for residential, commercial, and industrial settings. When selecting ball valves for water, it’s crucial to consider factors such as material, size, and pressure rating to ensure optimal performance and longevity. With their simple design and efficient operation, ball valves are indispensable for regulating water flow and maintaining system integrity.