A Comprehensive Guide to Actuated Ball Valves in Industrial and Residential Applications

Table of Contents

ToggleA Complete Guide to Actuated Ball Valves for Industrial and Residential Use

Welcome to the ultimate guide to actuated ball valves, a critical component in both industrial and residential settings. In this comprehensive post, we will delve into the intricacies of electric actuated ball valves, pneumatic actuated ball valves (aka: air actuated ball valves), providing you with the knowledge and confidence to make informed decisions for your specific motorized ball valve applications.

Introduction

Actuated ball valves are essential components used in industrial applications to control the flow of various fluids and gases. These valves are actuated, meaning they are automated or remotely controlled, eliminating the need for manual operation.

Actuated ball valves can be operated through different methods such as electric and pneumatic actuation. Electric actuation involves the use of electric power to open or close the valve, while pneumatic actuation uses compressed air to control the valve’s movement.

In industrial settings, actuated ball valves play a crucial role in regulating the flow of liquids and gases, ensuring precise control and efficient operation. They are widely used in industries such as oil and gas, water treatment, chemical processing, and more.

Understanding the significance and functionality of actuated ball valves is vital for professionals and engineers working in industrial automation and fluid control systems. In this post, we will delve deeper into the different aspects of actuated ball valves, including their types, applications, and the benefits they offer in industrial processes.

Understanding Actuated Ball Valves

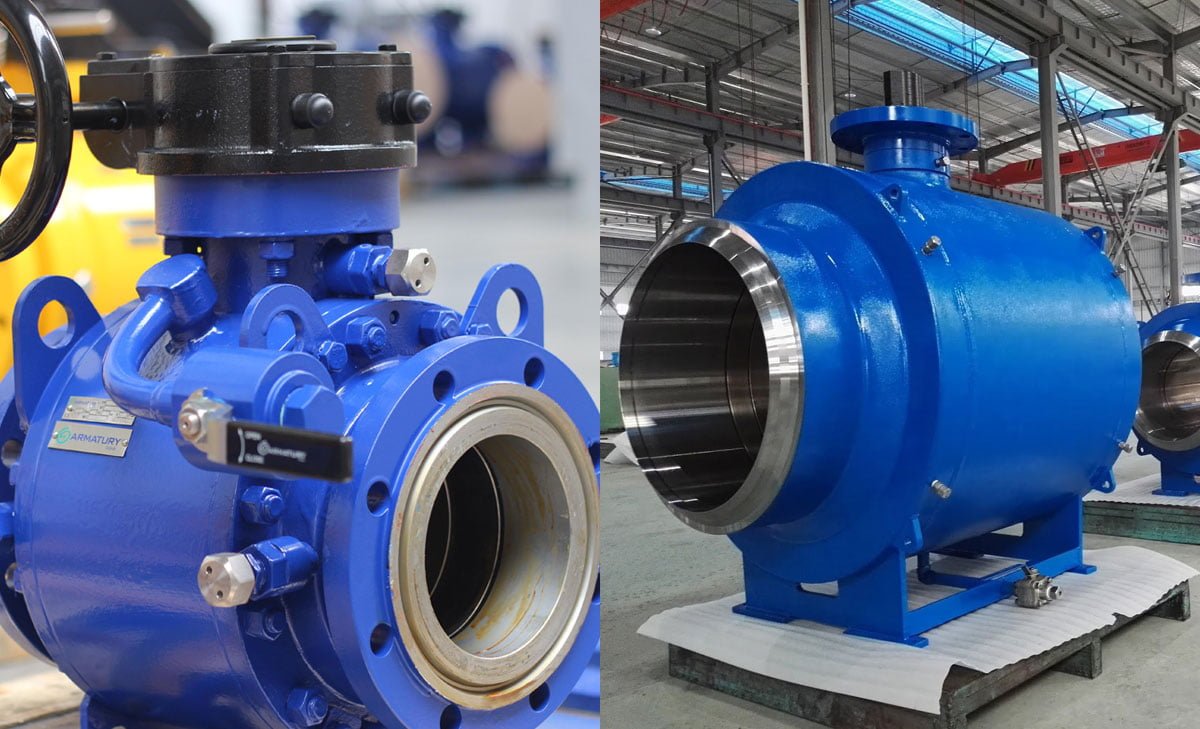

Ball valves are an essential component in the regulation and control of fluid and gas flow within pipelines and industrial systems. These valves encompass a straightforward yet highly efficient design, allowing for precise shut-off and regulation of flow. They consist of a pivoting ball with a bore, which, when aligned with the flow, allows the fluid or gas to pass through. Conversely, when the ball is rotated 90 degrees, the bore becomes perpendicular to the flow, effectively shutting off the passage.

What are Actuated Ball Valves?

Motorized (actuated) ball valves consist of a pivoting ball within the valve body, which can be rotated to control the flow of fluids or gases. The ball has a hole, or port, through the center, allowing the media to flow through when aligned with the pipe. These valves are used to start, stop, and throttle the flow of process media. Their primary function is to ensure optimal flow control and provide a reliable shut-off mechanism to prevent backflow.

Types of Actuated / Motorized Ball Valves

Actuated ball valves are available in various actuation methods, each tailored to specific applications and operational requirements:

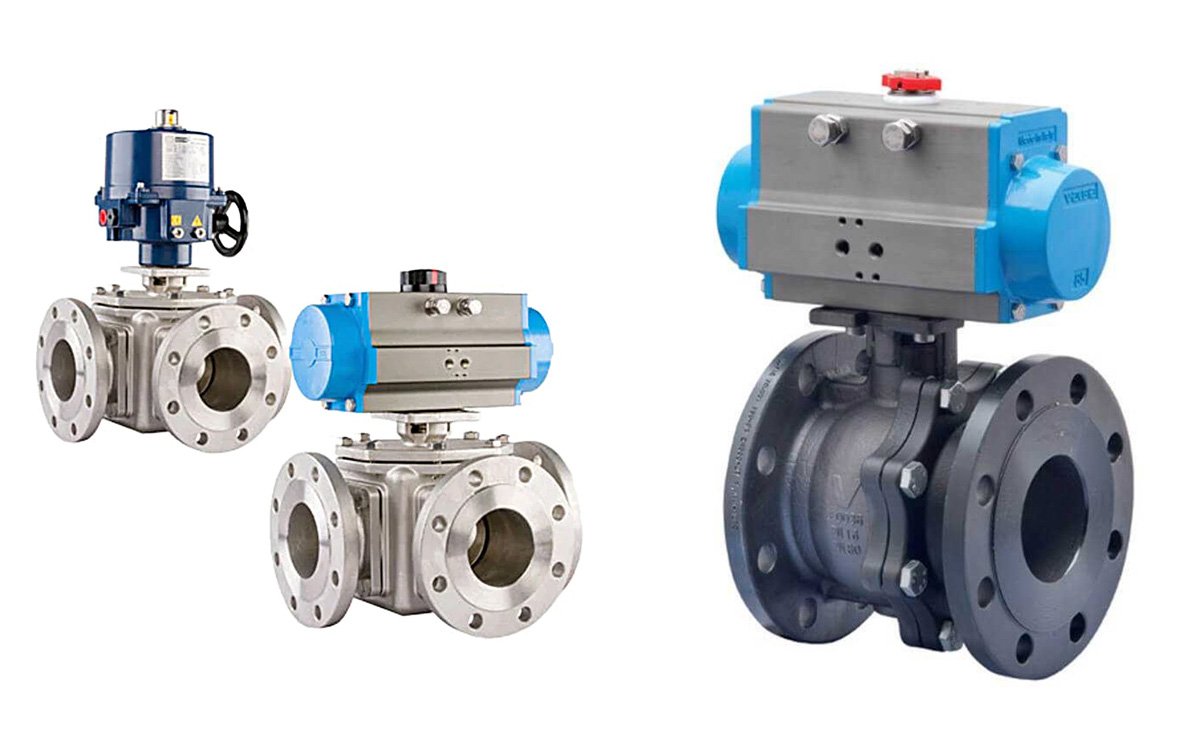

Electric Actuated Ball Valves

These valves are powered by an electric motor to control the ball rotation, allowing for precise and automated flow control. The electric actuation method is ideal for applications requiring remote operation, precise flow adjustment, and integration with automated systems.

Pneumatic (Air Actuated) Ball Valves

Pneumatic actuation utilizes compressed air to drive the valve’s actuator, resulting in quick and reliable valve operation. These valves are well-suited for applications where electricity may not be readily available or in hazardous environments where electric actuation is impractical.

Each actuation method presents unique features and benefits, catering to a diverse range of industrial applications. While electric actuated ball valves provide precision and automation, pneumatic and motorized ball valves offer dependable operation in different environmental conditions, ensuring optimal fluid control and system performance.

By understanding the fundamental mechanisms and types of actuation methods for ball valves, industries can make informed decisions when selecting the most suitable valve solutions for their specific operational requirements.

Detailed Analysis of Actuated Ball Valve Types

Actuated ball valves are crucial components in various industrial applications, providing reliable control of fluid flow. Understanding the different types of motor operated ball valves is essential for selecting the most suitable option for specific operational requirements. In this comprehensive analysis, we delve into the intricacies of electrical and pneumatic ball valves to provide a detailed understanding of their functionalities and advantages.

1. Electric Actuated Ball Valves

Electric actuated ball valves are equipped with electric actuators that offer precise control over the valve’s opening and closing mechanisms. These valves are ideal for applications requiring automated and remote operation, providing seamless integration with control systems. The electric actuators enable quick response times, making them suitable for processes that demand rapid adjustments in fluid flow.

These ball valves are highly versatile, accommodating various voltages and control signals, including analog and digital options. This flexibility allows for seamless integration into diverse industrial environments, enhancing operational efficiency and control precision. Additionally, electric actuated ball valves are known for their robust construction and reliable performance, ensuring long-term functionality in demanding applications.

2. Pneumatic Actuated Ball Valves

Pneumatic actuated ball valves utilize compressed air or gas to drive the actuator, facilitating efficient valve operation. These valves are valued for their rapid response and high-force output, making them suitable for applications requiring quick and powerful valve actuation. The pneumatic actuators offer reliable performance in challenging environments, exhibiting resilience against temperature fluctuations and harsh operating conditions.

Pneumatic actuated ball valves are favored for their simplicity and cost-effectiveness, providing an economical solution for fluid flow control systems. Their robust design and low maintenance requirements make them well-suited for applications where reliability and durability are paramount. Furthermore, pneumatic actuated ball valves can be easily integrated with control systems, offering seamless automation capabilities for enhanced operational control.

In conclusion, the analysis of electrical and pneumatic ball valves underscores their distinct characteristics and operational advantages. Selecting the appropriate valve type depends on specific application requirements, considering factors such as control precision, response time, environmental conditions, and integration with existing systems. By leveraging this comprehensive understanding, industrial operators can make informed decisions when implementing ball valves to optimize fluid flow control in diverse operational settings.

Advantages of Actuated Ball Valves

Actuated ball valves offer several distinct advantages that make them a preferred choice in various industries. In comparison to traditional manual valves, actuated ball valves stand out due to their reliability, durability, and efficiency in fluid control.

Reliability and Durability

Actuated ball valves are known for their enhanced reliability and durability. Unlike manual valves, actuated ball valves provide precise and consistent control over fluid flow, reducing the risk of leakage and ensuring reliable operation even in harsh conditions. Industries such as oil and gas, chemical processing, and water treatment rely on the robustness of actuated ball valves to maintain operational integrity and prevent costly downtime. The ability of these valves to withstand high pressures and temperatures further enhances their suitability for demanding applications, making them a dependable choice for critical fluid control systems.

Efficiency in Fluid Control

One of the key advantages of actuated ball valves is their contribution to efficient fluid control. By facilitating precise regulation of fluid flow, these ball valves enable improved operational performance and a reduction in energy consumption.

Industries seeking to optimize their processes, such as HVAC, power generation, and pharmaceuticals, benefit from the ability of actuated ball valves to streamline fluid handling and minimize waste. The efficient operation of these valves leads to cost savings and environmental sustainability, making them an essential component in modern fluid control systems.

In summary, the reliability, durability, and efficiency in fluid control offered by these ball valves make them indispensable in various industries, providing consistent and precise fluid regulation while promoting operational efficiency and resource conservation.

Applications of Actuated Ball Valves

Motorized ball valves find a wide range of applications in various sectors, owing to their efficiency, reliability, and versatility. Let’s delve into the diverse industrial and commercial/residential implementations of these valves.

Industrial Sector Implementations

In the industrial realm, actuated ball valves play a crucial role in a multitude of applications. They are extensively utilized in manufacturing processes, ensuring precise control and regulation of fluids such as chemicals, acids, and solvents.

Additionally, these valves are pivotal in water treatment plants, where they facilitate the management of water flow, aiding in purification and distribution processes.

Furthermore, motorized ball valves are integral components in the oil & gas industry, where they are employed for controlling the flow of various substances within pipelines and refining operations.

Commercial and Residential Use

In commercial and residential settings, ball valves serve diverse purposes, contributing to the efficient functioning of systems. Within HVAC (Heating, Ventilation, and Air Conditioning) systems, these valves enable accurate modulation of air and fluid flow, ensuring optimal environmental control.

In plumbing applications, motorized ball valves are instrumental in regulating the flow of water within pipelines, enhancing overall safety and efficiency. Moreover, these valves play a key role in utility management systems, effectively controlling the flow of gas, water, or other substances to meet specific requirements.

By seamlessly integrating into an array of industrial, commercial, and residential applications, actuated ball valves demonstrate their unparalleled adaptability and performance across various sectors.

Choosing the Right Actuation Method

When selecting actuated ball valves, there are several crucial factors to consider to ensure that you choose the right valve for your specific application. Here’s a comprehensive guide on how to make the best choice, including considerations for selection and a comparison between electric and pneumatic options.

Considerations for Selection

Actuated ball valves are essential components in various industrial applications, offering reliable flow control. When selecting motorized ball valves for your system, it’s crucial to consider several factors to ensure optimal performance and efficiency.

1. Valve Size and Pressure Rating

Choosing the right valve size and pressure rating is crucial for ensuring the proper flow and pressure control within your system. Consider the flow requirements and the maximum pressure the valve will be subjected to in order to select the appropriate size and pressure rating.

2. Valve Material and Compatibility

The material of the actuated ball valve plays a significant role in its performance and longevity. Consider the compatibility of the valve material with the fluid or gas it will be in contact with, ensuring resistance to corrosion, erosion, and other potential damage factors.

3. Actuator Type and Control Mechanism

Selecting the right actuator type and control mechanism is essential for efficient valve operation. Evaluate the specific requirements of your application to choose between electric, pneumatic, or hydraulic actuators, and consider the control mechanism that best suits your automation needs.

4. Environmental and Operational Conditions

Assess the environmental and operational conditions in which the motorized ball valve will be installed. Factors such as temperature, pressure variations, and exposure to corrosive substances should be taken into account to ensure the valve’s durability and reliability.

5. Compliance with Industry Standards

Ensure that the actuated ball valve complies with industry standards and regulations to guarantee its performance, safety, and reliability within your system. Look for certifications and approvals that validate the quality and adherence to industry standards.

6. Maintenance and Serviceability

Consider the ease of maintenance and serviceability of the ball valve. Select a valve design that allows for straightforward inspection, repairs, and part replacements to minimize downtime and ensure long-term functionality.

Conclusion for Considerations

When it comes to actuated ball valves, the selection process involves careful consideration of various technical and operational factors. By prioritizing aspects such as size, material, actuator type, environmental conditions, compliance, and maintenance, you can ensure the optimal performance and longevity of the ball valves in your industrial applications. By carefully considering these factors, you can ensure that the motorized ball valve you choose will provide reliable and efficient performance within your system.

Comparing Electric and Pneumatic Options

Electrical and pneumatic ball valves offer distinct advantages and are suitable for different applications. Here’s a comparison of the two options:

Electric Ball Valves: Electrically actuated ball valves are suitable for applications where precise control and automation are required. They allow for remote operation and can be integrated into sophisticated control systems. Electrical ball valves are ideal for applications where consistent and accurate valve positioning is crucial.

Pneumatic Ball Valves: Pneumatically actuated ball valves, also known as air actuated ball valves, are well-suited for applications requiring rapid and reliable actuation. They are often favored in industrial settings where compressed air systems are readily available. Pneumatic ball valves provide quick opening and closing, making them suitable for on/off applications in various industries.

By understanding the strengths and suitable applications of electric and pneumatic ball valves, you can make an informed decision based on the specific requirements of your system.

Remember that the choice between electrical and pneumatic ball valves depends on factors such as the nature of the application, available resources, and the level of control required. By carefully evaluating these considerations, you can select the most suitable actuated ball valve for your unique application needs.

Final Summary

Actuated ball valves are versatile and efficient components used in various industrial applications. Whether it’s electric or pneumatic, these valves offer precise control and reliable performance. Understanding the different types of actuation and their benefits can help in selecting the right valve for specific operational needs. In the following sections, we explored the functionality and advantages of electric ball valves, pneumatic ball valves, and the overall significance of motorized ball valves in industrial operations.

Summary of Electric Actuated Ball Valves

Electrical ball valves provide automated control, offering quick response times and precise positioning. They are suitable for applications requiring frequent operation and remote control. The simplified wiring and compatibility with various control systems make them a popular choice for modern industrial processes.

Insights into Pneumatic Actuated Ball Valves

Pneumatic actuated ball valves utilize air pressure for operation, making them suitable for hazardous or explosive environments. Their robust construction and rapid response make them ideal for critical shut-off applications. With features like fail-safe operation and easy maintenance, pneumatic ball valves are widely used in diverse industrial settings.

Significance of Motorized Ball Valves

Actuated ball valves play a crucial role in ensuring efficient fluid control and process automation. Their ability to handle high pressures, temperatures, and corrosive media makes them indispensable in industries such as petrochemical, pharmaceutical, and water treatment. Choosing the right actuated ball valve based on operational requirements is essential for achieving optimal system performance.

FAQ: Comprehensive Analysis of Actuated Ball Valves

What are actuated ball valves used for?

Actuated ball valves are used to control the flow of liquids or gases in industrial applications. The actuation allows for remote or automated operation, making them suitable for processes that require precise control and automation.

How do actuated ball valves work?

Actuated ball valves operate by using a rotating ball with a hole in it to control the flow of the media. When the valve is actuated, the ball rotates to either allow or block the flow of the substance through the valve, providing efficient control over the process.

What are the benefits of actuated ball valves?

Actuated ball valves offer benefits such as quick and reliable operation, minimal maintenance requirements, suitability for a wide range of applications, and the ability to integrate with automated control systems, enhancing overall process efficiency.

What factors should be considered when selecting actuated ball valves?

A comprehensive analysis of actuated ball valves should consider factors such as the type of actuation (manual, electric, pneumatic, etc.), material and design considerations, compatibility with specific media and operating conditions, control and automation requirements, and overall lifecycle cost analysis.

How can actuated ball valves optimize industrial processes?

Actuated ball valves can optimize industrial processes by providing precise control over fluid flow, reducing the risk of leaks or spills, enabling remote or automated operation, contributing to process efficiency, and supporting seamless integration with control systems for enhanced performance.

What are the key considerations for selecting actuated ball valves for a specific application?

Key considerations for selecting actuated ball valves include the type of actuation, material compatibility, pressure and temperature ratings, flow control requirements, environmental factors, maintenance needs, and the capability to integrate with existing or planned control systems.

What are the common challenges associated with actuated ball valves?

Common challenges with motorized ball valves include potential leakage, wear and tear due to frequent actuation, issues related to material compatibility, and the need for periodic maintenance to ensure optimal performance and longevity of your valves.

How actuated ball valves contribute to industrial efficiency?

Actuated ball valves contributes to industrial efficiency by enabling the selection of the most suitable valves for specific applications, optimizing control and automation processes, minimizing operational risks, and enhancing overall productivity and reliability.

What are the future trends in actuated ball valve technology and applications?

Future trends in motorized ball valve technology and applications include advancements in materials and design for improved performance and durability, increased integration with digital control and monitoring systems, and the development of smart actuated ball valves with enhanced sensing and communication capabilities.

Where can I find additional resources for in-depth analysis of actuated ball valves?

Additional resources for in-depth analysis of motorized ball valves can be found in industry publications, technical journals, manufacturer’s specifications, and research reports focusing on valve technology, industrial automation, and fluid control systems.

Conclusion

In conclusion, the diverse range of actuated ball valves, including electric and pneumatic variants, offer reliability, safety, and efficiency in fluid handling applications. By understanding their functionalities and benefits, industries can make informed decisions to enhance their operational processes and overall productivity.