Choosing the Right Globe Valve Manufacturer

Table of Contents

ToggleIntroduction

Are you in need of reliable globe valves for your industrial applications? Finding a reputable globe valve manufacturer is essential for ensuring the efficiency and safety of your operations. With a focus on precision engineering and quality materials, a trusted globe valve manufacturer can provide solutions that meet the demanding requirements of various industries. Whether you require customized designs or standard specifications, partnering with the right manufacturer is crucial for seamless integration and long-term performance.

Globe Valve Manufacturing Process

The manufacturing process of globe valves is a critical aspect that determines the quality and reliability of the final product. The materials selected for durability and performance, the steps involved in the production, and the rigorous quality control measures are all pivotal in ensuring the functionality and longevity of the globe valves.

Material Selection for Durability and Performance

The manufacturing process commences with the careful selection of materials. Globe valve manufacturers prioritize materials such as stainless steel, carbon steel, and alloy steel due to their exceptional durability and ability to withstand corrosion and high pressure. These materials are chosen for different components of the valve, ensuring overall robustness and longevity. The selection process is crucial in guaranteeing the valves’ ability to operate reliably under varying conditions, making them suitable for a wide range of industrial applications.

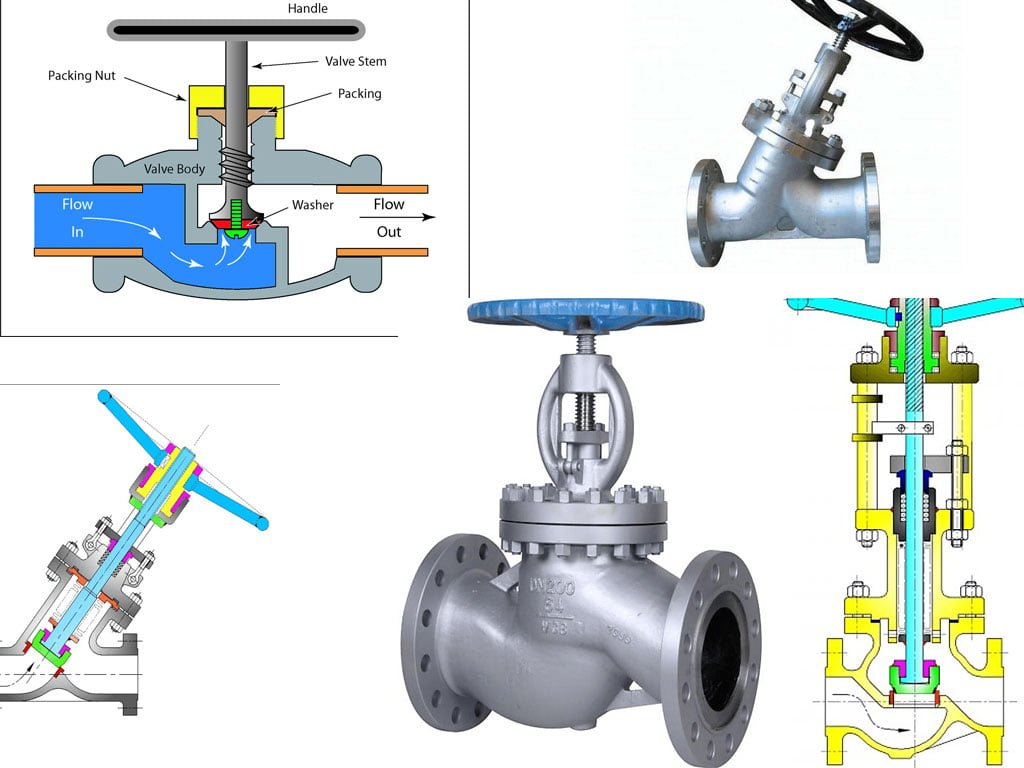

Steps in Globe Valve Production

The production of globe valves involves several precise steps to craft the components and assemble them into a functional unit. First, the chosen materials undergo shaping and machining processes to create the valve body, bonnet, plug, and other essential parts. Subsequently, these components are meticulously assembled, often using welding and brazing techniques, to construct the complete valve. The precision and attention to detail at every stage of the production process are imperative to ensure the valves’ optimal performance and reliability in diverse operational environments.

Quality Control in Valve Manufacturing

Quality control holds immense significance in globe valve manufacturing. Rigorous inspections and testing procedures are integrated throughout the production process to maintain the highest standards. Non-destructive testing methods such as ultrasonic testing and radiographic examination are employed to detect any material or structural imperfections. Additionally, pressure testing is conducted to validate the valves’ integrity and leak-tightness, ensuring they meet the specified performance criteria. The stringent quality control measures are instrumental in delivering globe valves that conform to industry standards and excel in operational efficiency and safety.

Leading Globe Valve Manufacturers

When it comes to sourcing globe valves, it’s imperative to identify reputable manufacturers that deliver top-notch products and innovate to meet industry needs. Reputable manufacturers adhere to specific criteria, including quality, reliability, and industry expertise. In the globe valve industry, there are several leading players that consistently set high standards for quality and innovation. These manufacturers have introduced notable advancements to enhance the performance and efficiency of globe valves, catering to diverse industrial requirements.

Criteria for a Reputable Globe Valve Manufacturer

A reputable globe valve manufacturer adheres to stringent quality standards and possesses a deep understanding of the complexities of fluid control within industrial processes. They prioritize the use of high-grade materials, precision engineering, and thorough testing to ensure the reliability and longevity of their valves. Moreover, reputable manufacturers exhibit a commitment to customer satisfaction, offering exceptional support and expertise to guide clients in selecting the most suitable globe valves for their applications.

Top Players in the Globe Valve Industry

In the realm of globe valve manufacturing, several industry giants stand out for their unwavering commitment to excellence. Companies such as Powell Valves, Velan Inc., and Cameron Valves have earned acclaim for their extensive product lines, technical expertise, and proven track records in delivering reliable and durable globe valves. These manufacturers have established themselves as leaders in the industry, consistently meeting the evolving demands of various sectors, including oil and gas, petrochemical, and power generation.

Innovations by Leading Manufacturers

Leading globe valve manufacturers have been at the forefront of innovation, introducing cutting-edge technologies and design enhancements to optimize valve performance. This includes advancements in materials, such as corrosion-resistant alloys and high-strength composites, to prolong valve lifespan and enhance operational efficiency. Furthermore, innovative features like smart valve monitoring systems and digital control interfaces have been integrated to provide real-time insights into valve operations, improving overall safety and productivity in industrial settings.

By prioritizing quality, embracing innovation, and maintaining a steadfast commitment to excellence, these leading manufacturers continue to shape the landscape of the globe valve industry, ensuring that businesses have access to reliable and high-performing valves to meet their operational needs.

Customization and Specialty for a Globe Valve Manufacturer

Tailoring Valves for Specific Applications

Customization plays a crucial role in meeting the diverse needs of industries when it comes to globe valves. Manufacturers with the capability to tailor valves based on specific requirements are highly sought after. For instance, in industries such as oil and gas, power generation, and petrochemicals, there is often a need for specialized globe valves that can withstand extreme temperatures, pressures, and corrosive environments. This necessitates the customization of materials, trim, size, and other valve components to ensure optimal performance in these demanding applications.

The Role of Customization in Industry Solutions

Customization of globe valves is pivotal in providing industry-specific solutions. By collaborating closely with manufacturers to customize globe valves, industries can address unique challenges effectively. Whether it’s the need for high-pressure sealing, cryogenic service, or control applications, tailored globe valves play a vital role in ensuring operational efficiency and reliability. Moreover, customization also allows for the integration of advanced features, such as special coatings, extended bonnets, and unique actuation methods, to align with industry requirements and standards. This indispensable role of customization in providing industry solutions highlights the significance of partnering with globe valve manufacturers capable of delivering tailored solutions to meet specific industrial needs.

Certifications and Standards for a Globe Valve Manufacturer

Certifications and compliance with industry standards are crucial factors to consider when selecting a globe valve manufacturer. These ensure that the valves meet the necessary quality and safety benchmarks.

Importance of Industry Certifications

Industry certifications such as ISO 9001, API, and CE are essential for globe valve manufacturers. These certifications signify adherence to stringent quality control processes, ensuring that the valves meet the required standards. Customers can rely on certified manufacturers for consistent product quality and performance.

Common Standards and Compliance

Globe valve manufacturers must comply with various standards such as API 600, API 602, and ANSI B16.34. These standards outline specific requirements for valve design, materials, and performance, ensuring that the valves are suitable for their intended applications. Compliance with these standards provides assurance of the valves’ reliability and longevity.

Choosing the Right Globe Valve Manufacturer

When selecting a globe valve manufacturer, there are several factors to consider to ensure that you are making the best choice for your business.

Factors to Consider When Selecting a Globe Valve Manufacturer

First and foremost, inspect the product quality of the valve supplier. A manufacturer’s product quality directly impacts the performance and longevity of the valves you purchase. Look for a manufacturer with strong qualifications, a reputable track record, and a robust quality inspection process. These elements are indicative of a manufacturer that can be trusted to deliver high-quality products that meet your standards.

Next, look at the price/performance ratio of the valve supplier’s products. While budget considerations are important, it’s essential to strike a balance between cost and quality. Avoid being swayed solely by low prices, as high-quality valves are often associated with reliable materials and may come at a higher cost. Aim to identify a manufacturer that offers cost-effective solutions without compromising on quality.

Lastly, inspect the after-sales service of the valve supplier. A manufacturer’s commitment to after-sales service is critical for ensuring ongoing support and assistance. A history of responsive and effective after-sales service is a strong indicator of a manufacturer’s dedication to customer satisfaction. Prioritize manufacturers that demonstrate a proactive approach to addressing customer inquiries and concerns in a timely manner.

The Impact of Manufacturer Location on Supply Chain

The location of a globe valve manufacturer can significantly impact your supply chain efficiency. Proximity to your business can lead to reduced lead times, lower shipping costs, and improved communication. Additionally, local manufacturers may offer greater flexibility and responsiveness to your specific needs, contributing to a streamlined procurement process.

On the other hand, global manufacturers may provide access to a wider range of options and specialized expertise. While distance can pose logistical challenges, leveraging the capabilities of a global manufacturer can result in access to innovative technologies and a broader market perspective.

By assessing the location of a manufacturer in relation to your supply chain requirements, you can make an informed decision that optimizes logistical efficiency and aligns with your business objectives.

Future Trends for a Globe Valve Manufacturer

The future of globe valve manufacturing is set to be shaped by technological advancements and global market developments. Let’s delve into the key areas that will drive the evolution of this industry.

Technological Advancements in Valve Manufacturing

Technological advancements in globe valve manufacturing are poised to revolutionize the industry. With the advent of 3D printing, manufacturers can now produce intricate valve components with unprecedented precision and efficiency. The use of advanced materials, such as corrosion-resistant alloys and polymers, is enabling the development of valves that offer superior performance and durability in demanding industrial environments. Additionally, the integration of smart technologies, including IoT sensors and predictive analytics, is enhancing the functionality of globe valves, enabling real-time monitoring and predictive maintenance.

The adoption of automation and robotics in valve manufacturing processes is streamlining production, reducing lead times, and minimizing errors. This not only improves operational efficiency but also ensures consistent quality across the production line. Furthermore, advancements in machining technologies are enabling the creation of complex valve geometries, optimizing flow characteristics and minimizing pressure drops.

Predictions for Global Market Developments

Looking ahead, the global market for globe valves is poised for significant developments. With increasing emphasis on sustainable practices, the demand for eco-friendly valve solutions is projected to rise. This shift is driving manufacturers to innovate and develop environmentally conscious valve technologies, such as low-emission and energy-efficient designs.

Moreover, the expansion of industrial infrastructure in emerging economies is expected to fuel the demand for globe valves in sectors such as oil and gas, water and wastewater treatment, and power generation. As a result, manufacturers are likely to focus on developing valves that can withstand harsh operating conditions while meeting stringent regulatory standards.

The growing trend of digitalization and Industry 4.0 initiatives is driving the integration of smart valves into industrial systems, fostering greater connectivity and control. This evolution presents opportunities for manufacturers to offer advanced valve solutions equipped with remote monitoring capabilities and data-driven insights, catering to the evolving needs of end-users.

In conclusion, the future of globe valve manufacturing holds immense potential, driven by technological innovations and global market dynamics. As manufacturers embrace these trends, the industry is set to witness a new era of innovation, sustainability, and enhanced performance in globe valve solutions.

Conclusion for Choosing a Globe Valve Manufacturer

In conclusion, choosing the right globe valve manufacturer is crucial for ensuring the efficiency and safety of your industrial operations. With a focus on high-quality materials, precision engineering, and reliable performance, a trusted globe valve manufacturer can provide the essential components for your fluid control systems. By considering factors such as industry experience, product range, and adherence to international standards, you can make an informed decision when selecting a globe valve manufacturer for your specific needs. With careful evaluation and attention to detail, you can secure a reliable supply of globe valves that meet the demands of your applications, contributing to the smooth and uninterrupted functioning of your systems.