The Advantages of Knife Gate Valves in Wastewater Treatment Plants

Table of Contents

ToggleUnderstanding the Functionality of Knife Gate Valves in Wastewater Treatment Plants

When it comes to wastewater treatment plants, the role of knife gate valves is crucial. These valves are specifically designed to withstand harsh environments and effectively manage heavy liquids. Their ability to resist corrosion, thanks to acid-proof stainless steel construction, makes them an ideal choice for such challenging applications. Unlike traditional gate valves, knife gate valves are adept at handling slurry media and are designed to operate in a completely open or closed position, making them well-suited for wastewater treatment plant operations.

- Efficient Slurry Handling: Knife gate valves are effective in handling slurries and solids in wastewater treatment plants, preventing clogging and blockages.

- Minimal Leakage: These valves provide a tight shut-off, minimizing the risk of leakage, which is crucial for preventing environmental contamination in wastewater treatment facilities.

- Space-Saving Design: Knife gate valves have a compact design, making them suitable for applications where space is limited, such as in wastewater treatment plants.

- Low Maintenance: The simple design of knife gate valves results in low maintenance requirements, reducing downtime and operational costs in wastewater treatment facilities.

- Bi-Directional Sealing: These valves offer bi-directional sealing, allowing for flow in both directions and providing flexibility in wastewater treatment plant operations.

- Corrosion Resistance: Many knife gate valves are constructed from corrosion-resistant materials, making them suitable for the harsh and corrosive environments often found in wastewater treatment plants.

- Cost-Effective Solution: With their low maintenance needs and efficient performance, knife gate valves offer a cost-effective solution for wastewater treatment plant operators.

- Abrasion Resistance: Knife gate valves are designed to withstand the abrasion caused by the movement of slurries and solids, ensuring durability in wastewater treatment applications.

Understanding Knife Gate Valves

What are knife gate valves used for?

Knife gate valves are employed in industries dealing with slurry, viscous fluids, and heavy oils, as well as in wastewater and clean water applications. These valves are particularly beneficial in wastewater treatment plants, chemical plants, mining, and cement plants due to their ability to handle corrosive and abrasive media.

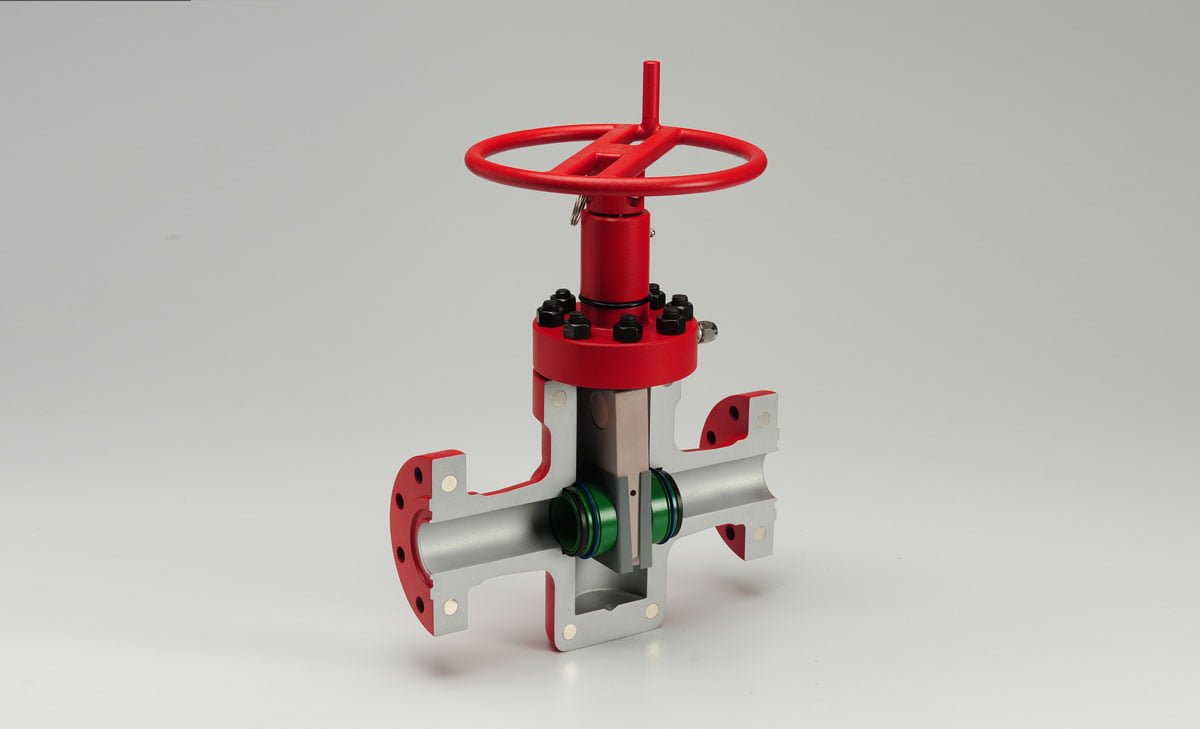

Basic Design and Operation

Knife gate valves are designed with a sharpened blade to effectively cut through heavy liquids, making them suitable for applications requiring a completely open or completely closed position. The valve’s slow opening and closing mechanism helps prevent the adverse effects of water hammer.

Are knife gate valves directional?

Knife gate valves are typically unidirectional, meaning they are meant to be installed in a specific orientation to ensure optimal performance and prevent flow reversal.

Knife Gate Valves vs. Traditional Gate Valves

Unlike traditional gate valves, knife gate valves are specifically designed for slurry and viscous media. They feature a shorter face-to-face length and a lighter weight, making them more suitable for challenging environments and applications.

What is the difference between a knife gate valve and a slide gate valve?

While both valve types serve similar purposes, knife gate valves are distinguished by their sharpened disc, allowing for better cutting through slurry and viscous media. Slide gate valves, on the other hand, are designed to create a tight seal in gravity-fed dry bulk material applications.

Key Materials Used in Knife Gate Valves

The construction of knife gate valves often involves the use of acid-proof stainless steel, which enhances their resistance to corrosion and minimizes maintenance requirements. Additionally, materials such as cast iron, carbon steel, and alloys are commonly employed to ensure durability and longevity in harsh operating conditions.

Role of Knife Gate Valves in Wastewater Treatment

Knife gate valves play a pivotal role in wastewater treatment plants due to their unique capabilities and properties. Here’s a detailed look at their significance in handling slurries and thick media, resistance to corrosion and wear, and their importance in wastewater applications.

Handling Slurries and Thick Media

Knife gate valves are engineered to effectively handle slurries and thick media commonly found in wastewater treatment plants. Unlike traditional valves, the design of a knife gate valve allows it to cut through thick, porous media with ease, ensuring smooth operations in the presence of high concentrations of suspended solids. This ability to navigate challenging substances makes them a valuable asset in maintaining efficient wastewater treatment processes.

Resistance to Corrosion and Wear

In the harsh environment of wastewater treatment, equipment is constantly exposed to corrosion and wear. Knife gate valves are specifically designed to withstand these challenges. Constructed from durable materials such as stainless steel and other alloys, they exhibit exceptional resistance to corrosion, ensuring longevity and reliability in wastewater applications. This resistance to wear and corrosion minimizes maintenance requirements, making them a cost-effective solution for wastewater treatment facilities.

Importance in Wastewater Applications

In wastewater treatment plants, the importance of knife gate valves cannot be overstated. Their unique ability to handle challenging media, coupled with their robust resistance to corrosion and wear, makes them indispensable components of the treatment process. From controlling the flow of sludge to managing thick media, knife gate valves play a critical role in ensuring the efficiency and reliability of wastewater treatment operations.

By effectively addressing the complexities of handling slurries and thick media, offering resistance to corrosion and wear, and serving as essential components in wastewater applications, knife gate valves emerge as indispensable assets in the realm of wastewater treatment.

Benefits of Knife Gate Valves for Wastewater Management

In the realm of wastewater management, the advantages of utilizing knife gate valves are substantial. These valves provide enhanced sealing capabilities, quick shut-off functionality, and minimal maintenance requirements, making them a valuable asset in wastewater treatment plants.

Enhanced Sealing Capabilities

Knife gate valves are designed to offer superior sealing performance, particularly in demanding wastewater applications. Their ability to effectively seal and prevent the passage of solid materials and abrasive media makes them ideal for controlling the flow of wastewater and sludge. This enhanced sealing capability minimizes the risk of leaks and ensures efficient operation within the wastewater treatment process.

Quick Shut-off Functionality

One key advantage of knife gate valves is their quick shut-off functionality. In wastewater treatment plants, the need for rapid response to shut off the flow of media is crucial. Knife gate valves excel in this aspect, providing swift closure to prevent the backflow of wastewater or slurry, thereby contributing to the overall safety and efficiency of the treatment process.

Minimal Maintenance Requirements

Another significant benefit of knife gate valves in wastewater management is their minimal maintenance requirements. These valves are constructed to withstand the harsh and abrasive nature of wastewater environments, reducing the need for frequent maintenance and replacement. The utilization of stainless steel knives in these valves further enhances their resistance to corrosion, resulting in extended service life and reduced downtime.

In wastewater treatment plants, the advantages of employing knife gate valves, such as enhanced sealing capabilities, quick shut-off functionality, and minimal maintenance requirements, play a pivotal role in ensuring the effective and reliable management of wastewater and sludge.

Installation and Maintenance Considerations

Ease of Installation

When considering knife gate valves for wastewater treatment plants, installation ease is a key factor. These valves are designed for simple installation, often requiring minimal space and time for setup. Their compact design and flexibility in mounting options make them suitable for various pipeline layouts. Additionally, the straightforward installation process reduces labor costs and downtime during plant maintenance or upgrades.

Guidelines for Maintenance and Care

To ensure optimal performance and longevity of knife gate valves in wastewater treatment plants, regular maintenance and care are essential. Establishing a proactive maintenance schedule that includes inspection, cleaning, and lubrication will help prevent potential issues. It is important to follow the manufacturer’s guidelines for maintenance to minimize wear and tear, extend the valve’s lifespan, and maximize operational efficiency.

Common Issues and Troubleshooting

Despite their durability, knife gate valves may encounter common issues over time. These can include leakage, blockages, or operational malfunctions. Implementing a comprehensive troubleshooting process is crucial to identify and address these issues promptly. This may involve checking for seal integrity, assessing the actuator functionality, or inspecting for any obstructions in the valve’s path. Regular monitoring and quick intervention can mitigate potential disruptions to the wastewater treatment process.

Safety and Environmental Impact

The use of knife gate valves in wastewater treatment plants offers significant benefits in terms of safety and environmental impact. These valves play a crucial role in preventing leaks and spills, contributing to safer work environments, and enhancing wastewater treatment efficiency.

Prevention of Leaks and Spills

Knife gate valves are designed to provide a tight seal, minimizing the risk of leaks and spills in wastewater treatment systems. Their ability to effectively control the flow of wastewater within the plant helps in preventing environmental contamination and maintaining a secure operational environment. By reducing the likelihood of leaks, knife gate valves contribute to the overall safety and integrity of the wastewater treatment process.

Contribution to Safer Work Environments

Incorporating knife gate valves into wastewater treatment systems promotes a safer work environment for plant operators and maintenance personnel. These valves enable precise flow control, reducing the potential for accidents and ensuring the safety of the individuals working in and around the treatment facilities. The capability of knife gate valves to handle abrasive and viscous media further enhances the overall safety of the work environment, mitigating the risks associated with handling wastewater in industrial settings.

Impact on Wastewater Treatment Efficiency

The utilization of knife gate valves results in improved efficiency in wastewater treatment processes. These valves facilitate seamless operation, allowing for precise regulation of fluid flow and consistent performance. By enhancing the control and management of wastewater within the treatment plant, knife gate valves contribute to the optimization of operational processes, ultimately leading to increased productivity and resource utilization.

Through their role in preventing leaks, promoting safer work environments, and optimizing wastewater treatment efficiency, knife gate valves serve as essential components in the pursuit of enhanced safety and environmental impact within wastewater treatment plants.

Selecting the Right Knife Gate Valve

Factors to Consider When Choosing a Valve

When selecting a knife gate valve for a wastewater treatment plant, several factors need to be taken into consideration. These include the type of material being processed, the size of the particles, the pressure and temperature conditions, as well as the frequency of operation. Understanding these operational parameters is crucial in choosing a valve that can withstand the specific demands of the application.

Customization for Specific Wastewater Needs

Wastewater treatment plants often have unique requirements based on the composition of the wastewater they are treating. Customization options for knife gate valves are essential to ensure optimal performance in these diverse environments. Whether it’s the material of construction, the actuation method, or the size and design of the valve, being able to customize the valve to the specific wastewater characteristics is paramount.

Vendor Selection and Support

Selecting a reliable and experienced vendor is as important as choosing the right valve. A reputable vendor not only provides high-quality valves but also offers valuable support in the selection process. They can assist in identifying the most suitable valve for the application, offer technical expertise, and provide ongoing support and maintenance services. When selecting a vendor, it’s important to consider their track record, industry reputation, and the level of support they can offer.

Conclusion

In conclusion, knife gate valves offer significant advantages in wastewater treatment plants and other industrial applications. Their design, optimized for slurry media, and acid-proof stainless steel construction make them highly resistant to corrosion, reducing the need for frequent maintenance or replacement. The ability to completely open or close, slow open and close to prevent water hammer, and the capability to handle heavy oils, non-flammable viscous fluids, and clean water further underscore the versatility and effectiveness of knife gate valves in wastewater treatment plants and various industrial settings.