The Advantages of Using Hydraulic Gate Valves

Table of Contents

ToggleThe Advantages of Using Hydraulic Gate Valves in Hydropower Generation Systems

Hydraulic gate valves play a crucial role in the efficient operation of hydropower generation systems. These valves are designed to regulate the flow of hydraulic fluid within the system, enabling precise control and management of the power generation process. In this article, we will explore the numerous advantages of utilizing hydraulic gate valves in hydropower generation systems, shedding light on their role in optimizing performance and ensuring reliable operation. Whether it’s enhancing flow control or maintaining consistent pressure levels, hydraulic gate valves offer a range of benefits that contribute to the overall efficiency and effectiveness of hydropower generation systems.

Understanding Hydraulic Gate Valves

Hydraulic gate valves are essential components in hydropower generation systems. They play a crucial role in regulating fluid flow and ensuring the efficient operation of hydropower plants. Understanding the function and components of hydraulic gate valves is vital for comprehending their significance in hydropower generation.

Definition and Function of Hydraulic Gate Valves

Hydraulic gate valves are designed to control the flow of fluid within a system. In hydropower generation, these valves are used to manage the water flow within the turbines, thus controlling the power generation process. The primary function of hydraulic gate valves is to regulate the fluid flow by either fully opening or fully closing the valve. This capability allows for precise control over the hydropower generation process, ensuring optimal efficiency.

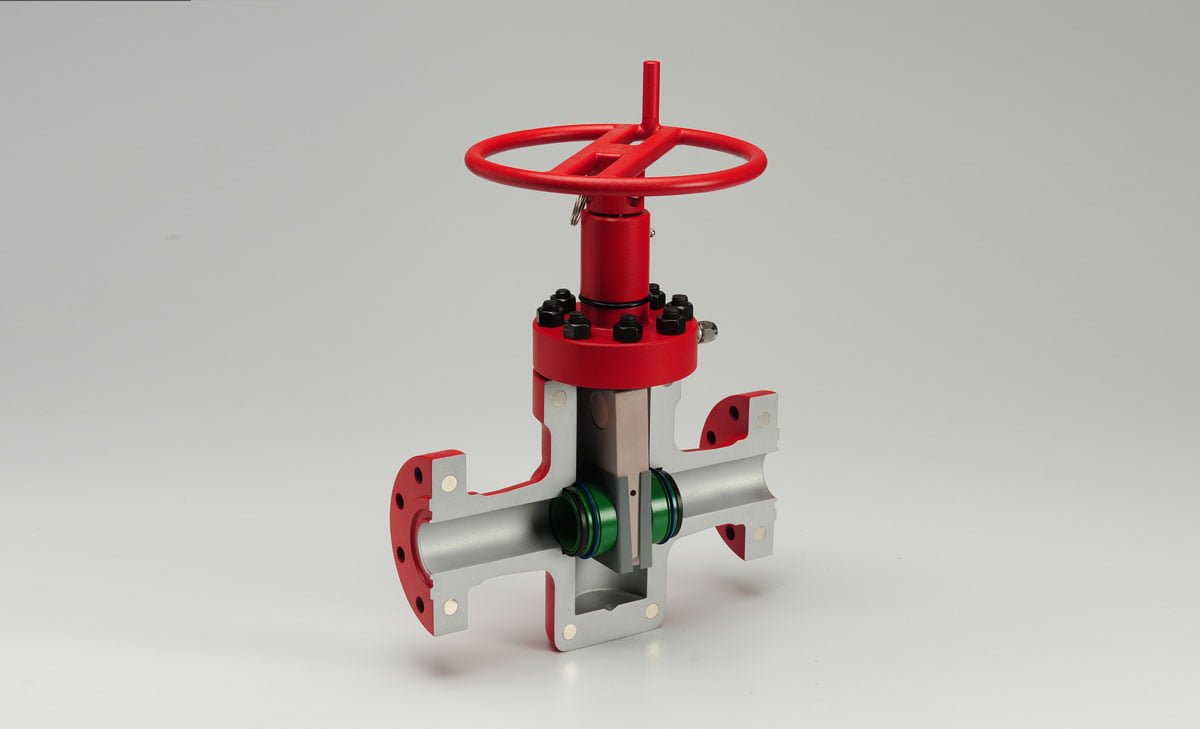

Key Components of a Hydraulic Gate Valve

The key components of a hydraulic gate valve include the body, seat, wedge, stem, gasket, hand wheel, and bonnet. These components work together to facilitate the smooth operation of the valve. The body serves as the main structure of the valve, housing the internal components and providing support. The seat and wedge are essential for creating a tight seal when the valve is in the closed position, preventing any fluid leakage. The stem, hand wheel, and bonnet enable the manual operation and maintenance of the valve, allowing for adjustments as needed.

Features of Hydraulic Gate Valves

- Pressure Resistance: Hydraulic gate valves are designed to withstand high pressure, making them suitable for applications involving intense fluid pressure.

- Effective Flow Control: These valves offer precise control over the flow of fluid, allowing for efficient regulation and distribution within a hydraulic system.

- Minimal Leakage: The design of hydraulic valves minimizes the risk of leakage, ensuring the integrity of the hydraulic system and preventing potential safety hazards.

- Durable Construction: Constructed from robust materials such as stainless steel or ductile iron, hydraulic gate valves are built to withstand demanding operational conditions and provide long-term reliability.

- Quick Operation: With their gate mechanism, these valves offer swift opening and closing actions, facilitating rapid response to changes in flow requirements.

- Adaptability: Hydraulic gate valves can be integrated into various hydraulic systems, offering compatibility with different configurations and setups.

- Maintenance-Friendly: Many hydraulic gate valves are designed for easy maintenance, with accessible internal components that allow for straightforward inspection and servicing.

- Corrosion Resistance: These valves are often engineered with protective coatings or materials to resist corrosion, ensuring longevity and performance in corrosive environments.

The Role of Hydraulic Gate Valves in Hydropower Systems

How Hydraulic Gate Valves are Integrated into Hydropower Plants

Hydraulic gate valves play a crucial role in the operation of hydropower generation systems. These valves are integrated into hydropower plants to control the flow of water, enabling efficient power generation. Typically, they are strategically positioned at various points within the plant to manage the movement of water and optimize energy production. The design and placement of this type of gate valves are meticulously planned to ensure seamless operation and effective regulation of water flow.

The Importance of Water Flow Regulation in Hydropower

Water flow regulation is of utmost importance in hydropower generation. Hydraulic gate valves facilitate precise control over the flow of water, allowing operators to adjust the volume and pressure as needed. This regulation is essential for maintaining the stability and reliability of the power generation process. By effectively managing water flow, hydropower plants can maximize energy output while ensuring the safety and sustainability of the entire system. The integration of hydraulic gate valves empowers hydropower plants to harness the natural force of water and convert it into a consistent and renewable energy source.

Advantages of Hydraulic Gate Valves Over Other Valve Types

Hydraulic gate valves offer distinct advantages over other valve types, making them a preferred choice for hydropower generation systems. These advantages include superior sealing capabilities, enhanced durability, and low flow resistance.

Superior Sealing Capabilities for Effective Water Control

Hydraulic gate valves are designed to provide exceptional sealing capabilities, ensuring effective control of water flow within hydropower generation systems. The robust sealing mechanism prevents leakage, enabling precise regulation of water passage without any loss of pressure. This feature is crucial for maintaining operational efficiency and maximizing the power output of hydropower plants.

Enhanced Durability for High-Pressure Environments

In high-pressure environments commonly found in hydropower generation systems, durability is paramount. Hydraulic gate valves are constructed with materials and engineering that allow them to withstand extreme pressure conditions without compromising performance. Their robust design and construction make them well-suited for the demanding operational requirements of hydropower facilities, ensuring long-term reliability and minimal maintenance.

Low Flow Resistance for Optimal Energy Efficiency

One of the key advantages of hydraulic gate valves is their low flow resistance, which contributes to optimal energy efficiency in hydropower generation systems. By minimizing flow restrictions, these valves enable seamless water passage, reducing energy losses and enhancing overall system efficiency. This feature is particularly advantageous for maximizing power generation and optimizing the performance of hydropower plants.

Hydraulic valves stand out as a superior choice due to their exceptional sealing capabilities, durability in high-pressure environments, and low flow resistance, making them an indispensable component in hydropower generation systems.

Operational Benefits of Hydraulic Gate Valves in Hydropower

Hydraulic gate valves play a crucial role in hydropower generation systems, offering several operational advantages that contribute to efficient power generation and system reliability.

Precision in Flow Control for Consistent Power Generation

Hydraulic gate valves provide precise flow control, ensuring consistent power generation by regulating the flow of water through turbines. This precision allows for optimal utilization of water resources, maximizing energy output while minimizing wastage. The ability to adjust flow rates according to demand enables hydropower plants to adapt to varying energy needs, enhancing overall operational efficiency.

Reliability and Reduced Maintenance Needs

The robust design of hydraulic gate valves contributes to their reliability in hydropower systems. With fewer mechanical components susceptible to wear and tear, these valves require minimal maintenance, reducing downtime and operational disruptions. The inherent durability of this type of gate valves ensures consistent performance over extended periods, offering long-term operational reliability for hydropower generation facilities.

Safety Features Unique to Hydraulic Gate Valves

Hydraulic gate valves are equipped with safety features that are specifically tailored to the demands of hydropower applications. Emergency shut-off capabilities and fail-safe mechanisms ensure safe and efficient operation, mitigating potential risks associated with water flow control. Additionally, the ability to integrate advanced control systems enhances the overall safety and responsiveness of hydropower generation systems, providing reliable protection against unforeseen operational contingencies.

Hydraulic gate valves represent a critical component in hydropower generation, delivering precise flow control, operational reliability, and specialized safety features essential for sustainable and efficient power generation.

Case Studies: Successful Implementations of Hydraulic Gate Valves

Increased Efficiency in Large-Scale Hydropower Plants

Hydraulic gate valves have shown remarkable success in increasing the efficiency of large-scale hydropower plants. When integrated into the power generation system, hydraulic gate valves allow precise control over the flow of water, optimizing energy output. By regulating the water flow, these valves enable hydropower plants to operate closer to peak efficiency levels, thereby maximizing power generation.

The flexibility of hydraulic gate valves in adjusting water flow rates ensures that hydropower plants can adapt to varying operational demands, ultimately enhancing overall efficiency. This adaptability is critical for hydropower plants situated in areas with fluctuating water levels or seasonal changes, as it enables them to maintain consistent energy output despite external factors.

Long-Term Cost Savings from Using Hydraulic Gate Valves

In addition to improving operational efficiency, the utilization of hydraulic gate valves in hydropower generation systems contributes to long-term cost savings. These valves are designed to withstand the demanding conditions present in hydropower plants, offering durability and reliability over extended periods.

The precise flow control capabilities of a hydraulic gate valve minimize energy losses, leading to reduced operational costs for hydropower plants. Furthermore, the longevity of these valves translates to lower maintenance expenses and decreased downtime, resulting in substantial cost savings over the lifespan of the power generation system.

The implementation of a hydraulic gate valve not only enhances efficiency but also delivers significant financial benefits, making it a valuable investment for large-scale hydropower plants.

Future Innovations in Hydraulic Gate Valve Technology

Advances in Materials and Design

Hydraulic gate valve technology is advancing rapidly, particularly in the areas of materials and design. Engineers and manufacturers are constantly researching and developing new materials that offer improved strength, durability, and resistance to corrosion. With the use of advanced alloys and composite materials, hydraulic gate valves are becoming lighter, yet stronger, allowing for more efficient operation and longer service life. Furthermore, innovative design concepts are being incorporated to optimize fluid dynamics and reduce energy losses within the system, resulting in enhanced overall performance and reliability.

Integration with Smart Technology for Improved Performance

The integration of smart technology into hydraulic gate valve systems is revolutionizing the way these components operate. By leveraging sensors, actuators, and real-time monitoring systems, hydraulic gate valves can now be equipped with intelligent control features that enable autonomous adjustments based on varying operational conditions. This not only ensures precise flow regulation but also allows for predictive maintenance, minimizing downtime and optimizing efficiency. Additionally, the integration of smart technology enables seamless communication with centralized control systems, facilitating comprehensive data analysis and enabling proactive decision-making for enhanced system performance.

Conclusion

In conclusion, the use of hydraulic gate valves in hydropower generation systems offers several advantages. These valves provide precise and efficient flow control, allowing for optimal power generation and energy distribution. Their robust construction and ability to withstand high pressures make them reliable components in hydropower plants. Additionally, hydraulic gate valves require minimal maintenance, reducing downtime and operational costs. Overall, the implementation of hydraulic gate valves contributes to the effectiveness and sustainability of hydropower generation systems.