Use of Flanged Ball Valves in Process Control

Table of Contents

ToggleEnhancing Efficiency and Safety:

Leveraging Flanged Ball Valves in Process Control Systems

Flanged ball valves play a crucial role in enhancing efficiency and safety in process control. These valves offer unique advantages, such as minimal friction during operation, reduced wear on the seal, and low opening and closing torque. They are widely used in various industries like petroleum, chemical, and urban water supply and drainage. The structural characteristics and design of flanged ball valves make them a preferred choice for applications requiring fluid resistance, reliable sealing, easy operation, and a wide range of applications. In this blog post, we will delve into the role of flanged ball valves in process control and explore their structural characteristics in detail.

Understanding Process Control in Industrial Applications

Process control in industrial applications plays a vital role in ensuring efficient and safe operations. This section delves into the basic principles of process control and highlights the importance of valve selection in process systems.

Basic Principles of Process Control

Process control involves the regulation and manipulation of various parameters within industrial processes to maintain desired levels of output. This can include monitoring and adjusting factors such as temperature, pressure, flow rates, and chemical composition. By continuously measuring these variables and making real-time adjustments, process control systems help optimize production efficiency and product quality. Additionally, process control is essential for ensuring the safety of equipment and personnel within industrial facilities.

Importance of Valve Selection in Process Systems

Valves are integral components of process control systems, serving as key tools for regulating the flow of fluids and gases within industrial pipelines. The selection of appropriate valves is critical in maintaining operational efficiency and safety. Factors such as material compatibility, pressure ratings, flow characteristics, and environmental conditions must be carefully considered when choosing valves for specific applications. Proper valve selection not only ensures smooth process control but also contributes to the overall reliability and safety of industrial systems.

What are Flanged Ball Valves?

Flanged ball valves are essential components in process control systems, playing a crucial role in regulating and controlling the flow of liquids and gases. These valves are designed to provide efficient performance, enhanced safety, and durability in various industrial applications.

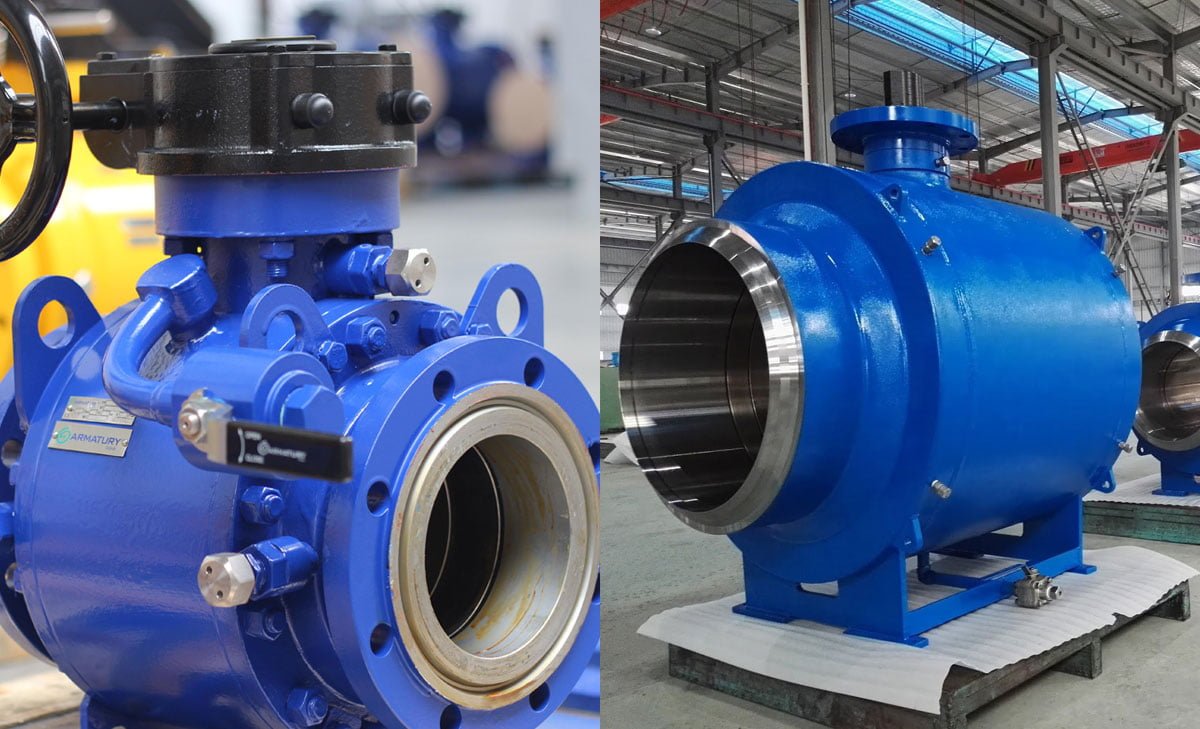

The Design and Features of Flanged Ball Valves

Flanged ball valves feature a spherical closure unit with a round disc (the ball) and are constructed with a flanged connection for easy installation and maintenance. The ball has a hole bored through the center to allow for the flow of fluid when aligned with the valve’s inlet and outlet ports. When the valve is closed, the ball is rotated 90 degrees, preventing the flow of the fluid.

These valves offer several key features, including the ability to withstand high pressures and temperatures, minimal leakage, quick operation, and reliable sealing, making them ideal for demanding process control environments.

Types of Flanged Ball Valves and Their Applications

Two-Piece Flanged Ball Valves

- These valves consist of two separate pieces, which allow for easier maintenance and repair. They are commonly used in applications where frequent maintenance is required.

Three-Piece Flanged Ball Valves

- Featuring a three-piece design, these valves offer easy disassembly for cleaning or maintenance. They are often utilized in applications requiring frequent inspection and maintenance.

Full Port Flanged Ball Valves

- With a larger ball and opening, these valves minimize friction loss and pressure drop, making them suitable for applications where unrestricted flow is essential.

Reduced Port Flanged Ball Valves

- These valves have a smaller ball and opening, which results in higher velocity and pressure drop. They are typically used in applications where flow control is critical.

Flanged ball valves find extensive applications in industries such as oil and gas, chemical processing, water and wastewater, pharmaceuticals, and more. Their versatility, reliability, and efficiency make them indispensable for ensuring safe and controlled fluid handling in various industrial processes.

Advancing Efficiency with Flanged Ball Valves

Flanged ball valves play a crucial role in enhancing efficiency and safety in process control. Let’s delve into how these valves improve flow regulation and their impact on system performance.

How Flanged Ball Valves Improve Flow Regulation

Flanged ball valves are designed to provide precise control over the flow of liquids, gases, and slurries in industrial processes. With their quarter-turn operation, these valves offer quick and efficient flow regulation, allowing for seamless adjustments to meet specific operational requirements. Their streamlined flow path minimizes pressure drop, ensuring smooth and uninterrupted flow throughout the system. This capability not only enhances operational efficiency but also contributes to cost savings by optimizing energy consumption.

The Impact of Flanged Ball Valves on System Performance

The utilization of flanged ball valves has a significant impact on overall system performance. By enabling reliable flow control, these valves help maintain optimal operating conditions, thereby maximizing productivity and minimizing downtime. Their robust construction and versatile sealing mechanisms ensure leak-free performance, enhancing system reliability and safety.

Additionally, the inherent durability of flanged ball valves ensures long-term performance, reducing the need for frequent maintenance and replacement. This reliability contributes to improved operational efficiency and ultimately supports a safer working environment.

In summary, the versatility and precision offered by flanged ball valves make them indispensable for achieving efficiency and safety in process control applications. Their ability to facilitate precise flow regulation and positively influence system performance underscores their vital role in various industrial processes.

Safety Enhancements Provided by Flanged Ball Valves

The Role of Flanged Ball Valves in Preventing Leaks

Flanged ball valves play a critical role in preventing leaks within process control systems. Their robust design and construction create a strong seal, effectively containing fluids and gases within the piping system. The ball within the valve, when in the closed position, forms a tight seal against the valve seat, preventing any potential leakage. This feature provides a reliable safeguard against the escape of hazardous substances, ensuring a secure and controlled industrial environment.

Ensuring Safety with Flanged Ball Valves in High-Pressure Environments

In high-pressure environments, safety is paramount, and flanged ball valves offer a reliable solution. The sturdy and durable construction of these valves enables them to withstand high pressure without compromising safety. The design of flanged ball valves ensures the integrity of the system even under extreme pressure conditions, allowing for the secure and efficient control of fluid flow. This capability provides peace of mind in environments where safety and reliability are of utmost importance.

Flanged Ball Valves in Different Industries

Flanged ball valves play a crucial role in various industries due to their efficient flow control and reliable shut-off capabilities. Let’s explore their applications in the oil and gas industry, chemical processing, and water treatment.

The Use of Flanged Ball Valves in the Oil and Gas Industry

In the oil and gas industry, flanged ball valves are instrumental in controlling the flow of crude oil, natural gas, and other fluids within processing and transportation systems. Their robust construction and ability to handle high pressure and temperatures make them ideal for critical applications such as pipeline isolation, metering, and tank farms. Ball valves provide quick and reliable shut-off, ensuring operational safety and efficiency in oil and gas operations.

Flanged Ball Valves in Chemical Processing

Chemical processing plants rely on flanged ball valves to regulate the flow of corrosive and abrasive fluids. With their corrosion-resistant materials and tight sealing performance, these valves are essential for handling various chemical processes, including mixing, blending, and distribution. Flanged ball valves contribute to maintaining process integrity and preventing leaks or contaminations, thereby enhancing safety and operational efficiency in chemical facilities.

Water Treatment and Flanged Ball Valves

In water treatment facilities, flanged ball valves are pivotal components for controlling the flow of water, chemicals, and wastewater. These valves are widely used in applications such as water distribution, filtration systems, and sewage treatment processes. Their ability to withstand harsh environmental conditions and provide reliable flow control makes them indispensable for ensuring the safety and effectiveness of water treatment operations.

Flanged ball valves serve as indispensable assets across diverse industrial sectors, offering precise flow regulation, dependable shut-off, and long-term durability. Their versatility and efficiency make them integral components in maintaining operational integrity and safety across oil and gas, chemical processing, and water treatment facilities.

Installation and Maintenance of Flanged Ball Valves

Best Practices for Installing Flanged Ball Valves

When it comes to installing flanged ball valves, it’s crucial to start with a comprehensive plan that considers the specific requirements of your system. Begin by thoroughly cleaning the pipeline to ensure there are no contaminants that could compromise the valve’s performance. Carefully align the valve with the pipeline and use the appropriate gaskets to prevent leakage.

Next, make sure to torque the fasteners to the manufacturer’s specifications to ensure a secure and reliable seal. It’s also important to verify that the valve is in the fully open position during installation to prevent any blockages caused by debris or foreign objects. Lastly, conduct a thorough inspection to guarantee the valve is installed correctly and is ready to function optimally.

Routine Maintenance for Prolonged Valve Life

Routine maintenance is essential for ensuring the prolonged life and efficiency of flanged ball valves. Regularly inspect the valves for any signs of wear, corrosion, or leakage. This can help identify potential issues before they escalate and affect the overall system performance.

Additionally, lubricate the valve components as specified by the manufacturer to maintain smooth operation and prevent premature wear. It’s also recommended to schedule periodic operational tests to assess the valve’s functionality and pinpoint any irregularities. Implementing a proactive maintenance schedule will not only extend the lifespan of the valves but also contribute to the overall safety and efficiency of the system.

Future Trends in Flanged Ball Valve Technology

Innovations in Flanged Ball Valve Designs

Flanged ball valve technology is experiencing significant advancements to meet the ever-evolving demands of process control systems. One notable innovation is the development of compact flanged ball valves, which offer a space-saving solution without compromising performance. These valves are designed to minimize the overall footprint while maintaining high flow capacity, making them ideal for applications where space is limited.

Additionally, manufacturers are integrating advanced materials such as corrosion-resistant alloys and high-strength composites to enhance the durability and longevity of flanged ball valves, ensuring reliable operation even in harsh industrial environments.

The Role of Smart Valves in Process Control

The integration of smart technologies is revolutionizing the functionality of ball valves flanged in process control. Smart valves are equipped with sensors and actuators that enable real-time monitoring and automated adjustments, offering unprecedented levels of precision and responsiveness.

By leveraging predictive analytics and connectivity features, smart flanged ball valves can optimize process efficiency, preemptively detect potential issues, and facilitate remote control and diagnostics. This enhanced intelligence not only improves operational performance but also contributes to overall safety by proactively identifying and addressing operational anomalies.

Conclusion

In conclusion, flanged ball valves play a crucial role in enhancing efficiency and safety in process control. With their unique advantages such as low fluid resistance, simple structure, tight reliability, easy operation and maintenance, and wide range of applications, flanged ball valves are a valuable choice for various industries including petroleum, chemical, and urban water supply and drainage.

The structural characteristics of ball valves flanged, such as the absence of friction when opening and closing, top installation structure, single valve seat design, low torque design, and wedge-shaped sealing structure, further contribute to their efficiency and safety in process control. By understanding the advantages and structural characteristics of flanged ball valves, industries can make informed decisions to optimize their process control systems.