Full Port Ball Valves: An Essential Component

Table of Contents

ToggleIntroduction to Full Port Ball Valves

There are two main types of ball valve ports: standard and full port. The primary difference lies in the diameter of the valve port in comparison to the pipe’s diameter. Full port ball valves have the same diameter as the pipe, while a standard port valve has a smaller port size than the pipe’s diameter.

Full port (or full bore) ball valves offer minimal resistance to the flow of liquid or gas due to their straight flow path, resulting in very low pressure drop when fully open. In contrast, standard port ball valves, with their smaller opening, cause a larger pressure drop even when fully open, potentially leading to a cavitation risk in certain applications.

It is important to note that gate and globe valves are almost always full port by design, as their respective functions require a full port design.

What Sets Full Port Ball Valves Apart

Defining Full Port Ball Valves

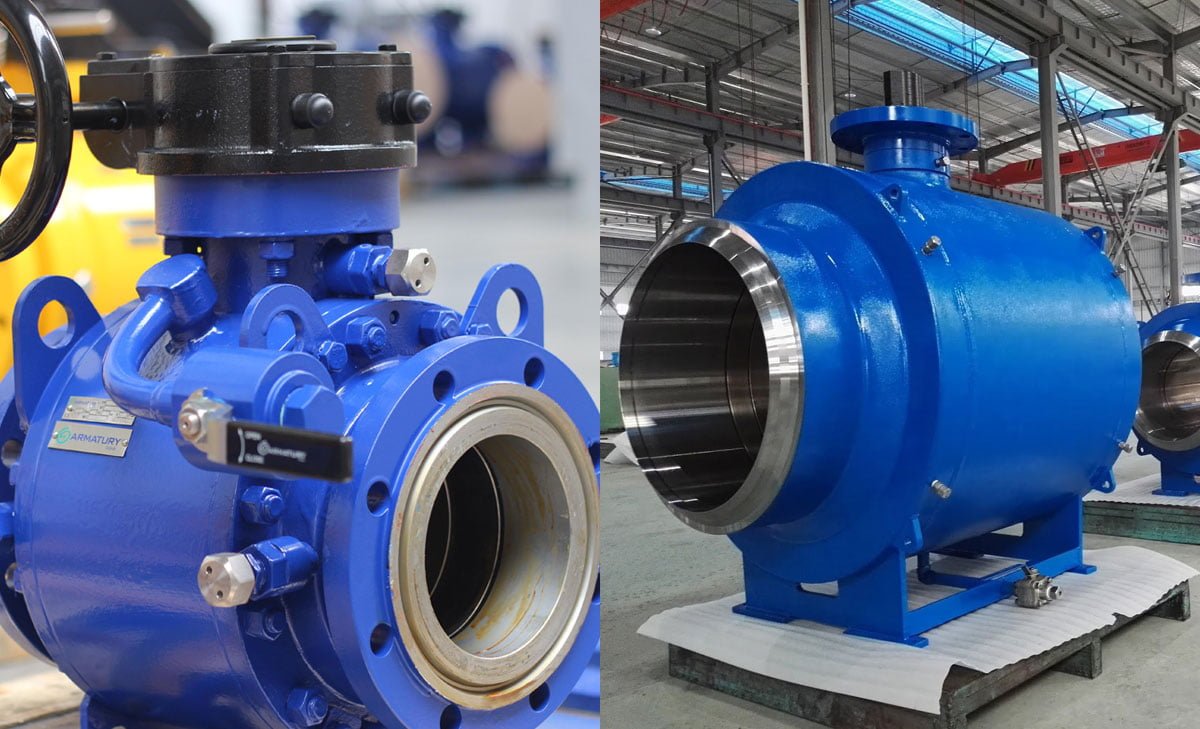

A full port ball valve is designed to provide unrestricted flow when fully opened, with larger bodies and a larger ball opening compared to standard valves, allowing for minimal flow loss. The valve’s size matches that of the pipes it serves, facilitating smooth material passage when in the open position.

Standard vs. Full Port Ball Valves

The key difference lies in the flow capacity. Full port ball valves are suitable for applications requiring minimal flow restriction and constant flow rate maintenance, while standard port valves are cost-effective solutions for controlling flow in various applications, especially in space-limited scenarios. The decision between the two depends on the specific application requirements and space limitations.

Advantages of Full Port Ball Valves

Minimized Flow Resistance

Full port ball valves are designed to reduce flow resistance, enabling smoother flow of liquids or gases through the pipeline. Unlike standard valves, which can cause pressure drops and turbulence, full port ball valves provide an unobstructed flow path, allowing for efficient and unrestricted movement of the medium. This reduction in flow resistance not only enhances the overall performance of the system but also minimizes the wear and tear on the valve, leading to longer service life and decreased maintenance requirements.

Energy Efficiency Considerations

In industries where energy efficiency is a critical consideration, full port ball valves offer significant advantages. By minimizing flow resistance, these valves contribute to reduced energy consumption, making them an ideal choice for applications where energy conservation is a priority. The unrestricted flow path provided by full port ball valves allows for efficient fluid movement, ensuring that the system operates at optimal energy levels. This can result in cost savings and environmental benefits, making full port ball valves a preferred choice for energy-conscious industries.

Common Applications of Full Port Ball Valves

Full port ball valves find diverse applications across industrial, residential, and commercial plumbing sectors, offering efficient flow control and reliable performance.

Industrial Usage of Full Port Ball Valves

In industrial settings, full port ball valves are utilized in various applications demanding unrestricted flow. These valves are commonly employed in chemical processing, oil and gas, water treatment plants, and manufacturing facilities. With their full-bore design, they ensure minimal flow resistance, making them ideal for processes involving large volumes of fluid and low-pressure drop requirements. Their robust construction and ability to handle high temperatures and pressures make them suitable for critical industrial operations.

Residential and Commercial Plumbing

In residential and commercial plumbing systems, full port ball valves are utilized for their effective flow control capabilities. These valves are commonly integrated into water distribution systems, HVAC systems, and fire protection systems. Their full-bore design allows for efficient water flow, contributing to optimal system performance and reliability. Additionally, full port ball valves are preferred in applications where maintenance and repair activities must be minimized, providing long-term durability and dependable operation for both residential and commercial plumbing installations.

Installation and Maintenance Tips for Full Port Ball Valves

Proper Installation Practices

When installing a full port ball valve, it’s essential to ensure that the valve is placed in a way that allows for easy access for operation and maintenance. Proper alignment and support are crucial to prevent strain on the valve and the surrounding piping system. It is also important to follow the manufacturer’s guidelines for installation, including torque specifications for flange bolts or body connectors.

Routine Maintenance for Longevity

Routine maintenance is key to ensuring the longevity and optimal performance of a full port ball valve. Regular inspection for leaks, corrosion, or wear and tear is essential. Additionally, lubricating the valve components as recommended by the manufacturer can prevent operational issues and extend the valve’s lifespan. It is also important to monitor the valve’s performance and address any issues promptly to prevent further damage. Regular maintenance checks should be scheduled to ensure the valve operates smoothly and efficiently.

Choosing the Right Full Port Ball Valve

In selecting the right full port ball valve for your application, it’s essential to consider the material selection for different fluids, as well as the size and pressure ratings.

Material Selection for Different Fluids

When choosing a full port ball valve, it’s crucial to consider the compatibility of the valve’s material with the fluids it will handle. For corrosive or abrasive fluids, such as chemicals or slurries, valves made from materials like stainless steel, brass, or PVC are suitable choices. These materials offer excellent resistance to corrosion and erosion, ensuring longevity and optimal performance in challenging environments.

For applications involving high temperatures and pressures, materials like carbon steel or alloy steel are preferred due to their robustness and heat resistance. Consider the specific characteristics of the fluid being transported and select a full port ball valve constructed from a material that can withstand its unique properties.

Size and Pressure Ratings

The size of the full port ball valve should align with the flow requirements of the system. Larger valves allow for greater flow capacity, reducing the risk of pressure drops and ensuring efficient fluid conveyance. Consider the pipe size and flow characteristics to determine the appropriate valve size for seamless integration within the system.

In addition to size, it’s crucial to assess the pressure ratings of the full port ball valve. Different applications demand varying levels of pressure resistance, and selecting a valve with the appropriate pressure rating is paramount to avoiding system failures or leaks. Refer to the manufacturer’s specifications to identify the pressure limits of the valve and ensure compatibility with the operational pressures of the system.

By carefully evaluating material compatibility, size, and pressure ratings, you can confidently choose the right full port ball valve that aligns with the unique requirements of your fluid handling system.

Conclusion

In conclusion, a full port ball valve features a larger valve port that matches the diameter of the pipe, allowing for minimal resistance and pressure drop when fully open. This design reduces the risk of cavitation and erosion in the piping system. On the other hand, standard port ball valves have a smaller port size, causing a larger pressure drop and potential cavitation risk. Understanding the differences between these ball valve types and their respective applications is crucial for efficient and effective fluid control in various industries.