Guide to Stainless Steel Flanged Ball Valves

Table of Contents

ToggleThe Essential Guide to Stainless Steel Flanged Ball Valves

Stainless steel flanged ball valves are crucial components in various industries, offering reliable and efficient flow control. Whether you are a professional in the industrial sector or a homeowner looking to understand more about these valves, this comprehensive guide will provide you with all the essential information you need to know.

What Are Stainless Steel Flanged Ball Valves?

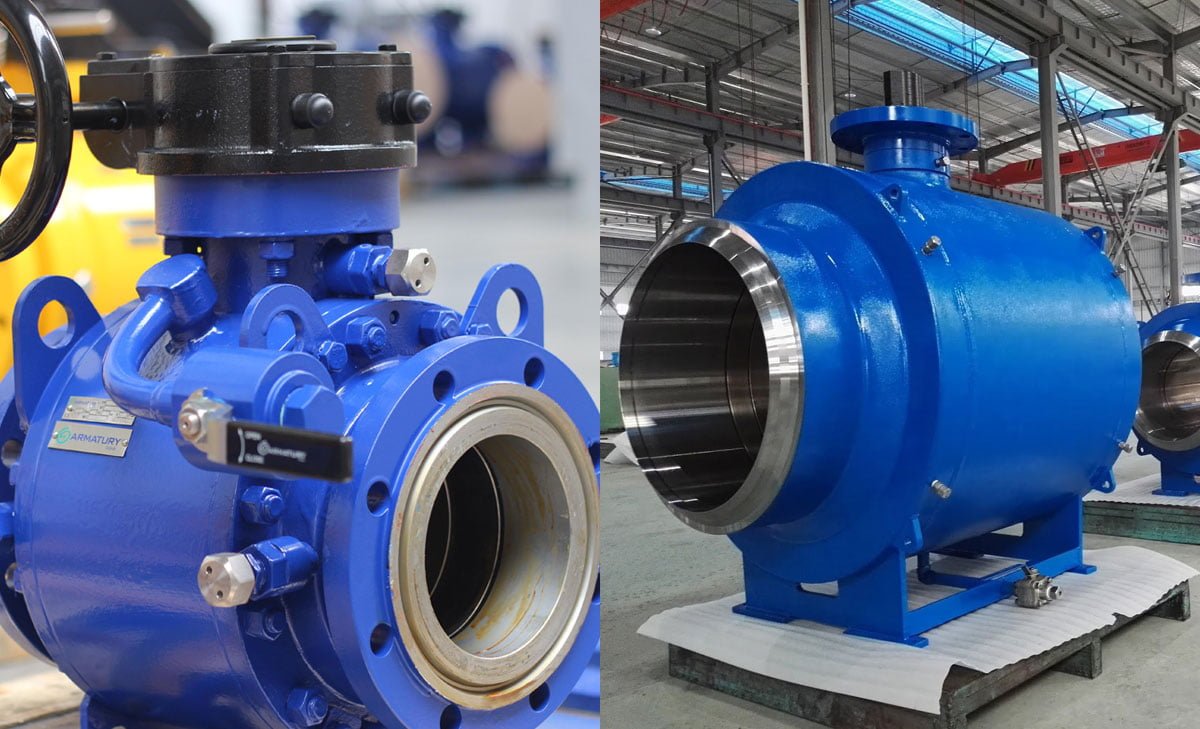

Stainless steel ball valves are essential devices used to control the flow of liquids or gases in a pipeline. The “ball” in the valve refers to the perforated, pivoting ball inside the valve that regulates the flow. The flanged design of these valves allows for easy installation and maintenance, making them a popular choice in industrial applications.

Construction and Components

Stainless steel flanged ball valves are constructed using high-grade stainless steel, which provides exceptional durability and corrosion resistance. The main components of these valves include the valve body, ball, stem, seat, and actuator. The robust construction of these components ensures reliable performance even in demanding environments.

Functionality and Applications

The functionality of stainless steel flanged ball valves lies in their ability to provide precise control over the flow of various media, including water, oil, gas, and chemicals. These valves are widely used in industries such as oil and gas, petrochemical, water and wastewater, pharmaceuticals, and food processing. Their versatility and effectiveness make them an ideal choice for numerous applications.

Advantages of Stainless Steel Flanged Ball Valves

Stainless steel flanged ball valves offer several advantages, including high corrosion resistance, long service life, and low maintenance requirements. Their design allows for quick shutoff, minimal pressure drop, and ease of automation. Additionally, they are suitable for both high and low-pressure applications, making them a versatile solution for diverse industrial needs.

Selection and Maintenance

When selecting a stainless steel flanged ball valve, it is essential to consider factors such as pressure ratings, temperature limitations, and media compatibility. Regular maintenance, including lubrication and inspection, is crucial to ensure optimal performance and extend the lifespan of the flanged valves.

Conclusion

Stainless steel flanged ball valves are indispensable components in industrial processes, offering reliable and efficient flow control. Understanding their construction, functionality, and advantages is essential for anyone involved in fluid handling systems. By considering the information provided in this guide, you can make informed decisions regarding the selection, installation, and maintenance of stainless steel flanged ball valves, ensuring smooth and safe operations in your application.