Mastering the 3-Way Ball Valve: A Complete Guide to Construction, Functionality, and Applications

Table of Contents

ToggleIntroduction

Dive into the world of 3-way ball valves as we unravel the construction, functionality, and diverse applications of these indispensable components. From the fundamental principles to the advanced variations such as the 3-way stainless steel ball valve, 3-way electric ball valve, and 3-way flanged ball valve, this guide is your gateway to mastering the intricacies of fluid control systems.

Enhancing Efficiency: How 3-Way Ball Valves Improve Flow Control

Three-way ball valves, also known as 3-way ball valves, are essential components in various industrial applications. These valves feature three ports and can be operated manually or automated with electric or pneumatic actuators. Available in both L-Port and T-Port configurations, 3-way ball valves offer versatile flow patterns to suit specific operational requirements.

With their unique design, 3-way ball valves play a pivotal role in controlling the flow of liquids and gases in complex piping systems. Their ability to divert, mix, or shut off the flow in different directions makes them invaluable in applications where precise flow control is necessary.

In this blog post, we will delve into the significance of 3-way ball valves, exploring their distinct features and highlighting their benefits across various industrial settings. Whether you’re familiar with these valves or are seeking to expand your knowledge of fluid control solutions, this post will provide valuable insights into the functionality and advantages of 3-way ball valves.

What Are 3-Way Ball Valves?

Three-way ball valves are versatile flow control devices commonly used in various industries. These valves feature three ports and a T or L-shaped internal bore, allowing for diversion or mixing of flow patterns. Let’s delve into the construction, functionality, and applications of 3-way ball valves.

Construction and Functionality

Design and Operational Principle

3-way ball valves are designed to provide flexibility in controlling the flow of fluids. The L-Port and T-Port configurations determine how the flow is directed within the valve. In the L-Port design, the ball has a hole through it, allowing for fluid to flow from one inlet to two different outlets, or vice versa. On the other hand, the T-Port configuration enables fluid to flow between the common port and one of the two other ports, or between the two non-common ports. This design allows for more diverse flow patterns and options for system control.

Role of L-Port and T-Port Configurations

The L-Port configuration is suitable for applications where flow diversion is required, such as directing flow to different outlets or switching between different sources. In contrast, the T-Port configuration is ideal for mixing applications, allowing fluid to be directed from one inlet into a single outlet or vice versa.

Applications in Fluid Control

Specific Scenarios

3-way ball valves find extensive use across diverse industries. In industrial processes, these valves are employed in systems that require flow diversion, mixing, or selection between different sources. In plumbing, they facilitate control over the distribution of water or other fluids, serving as essential components in complex plumbing systems. Additionally, in HVAC systems, 3-way ball valves play a crucial role in regulating the flow of heating and cooling fluids, enabling efficient temperature control within buildings.

Versatility and Functionality

With their ability to divert, mix, or select flow patterns, 3-way ball valves offer versatility in fluid control applications. They are often integrated into complex fluid handling systems to provide precise regulation and efficient management of fluid flow, making them indispensable in various operational environments.

By understanding the construction, functionality, and applications of 3-way ball valves, one can appreciate their significance in facilitating efficient fluid control across industries. Whether it’s managing fluid flow in industrial processes, plumbing systems, or HVAC settings, the adaptability and operational capabilities of these valves make them essential components for optimal system performance.

Different Types of 3-Way Ball Valves

When it comes to controlling flow in a piping system, 3-way ball valves are indispensable. They offer versatility and efficiency in redirecting flow in various directions. In this comprehensive guide, we will explore the different types of 3-way ball valves, including PVC, brass, stainless steel, electric, and flanged ball valves. Whether you’re a seasoned professional or a novice in the industry, this guide will provide you with valuable insights into the unique features and applications of each type of 3-way ball valve.

3-Way PVC Ball Valve

PVC 3-way ball valves are ideal for applications that require corrosion resistance and affordability. These valves are commonly used in water treatment, chemical processing, and irrigation systems. Their lightweight and durable construction make them suitable for both residential and industrial applications. Additionally, PVC 3-way ball valves are available in various sizes and configurations to accommodate different system requirements.

3-Way Brass Ball Valve

Brass 3-way ball valves are known for their exceptional durability and reliability. They are often preferred for applications involving compressed air, fuel, and oil. The inherent strength of brass makes these valves suitable for high-pressure environments, and they are also resistant to corrosion. Their versatility and ability to withstand varying temperatures make them a popular choice in industrial and commercial settings.

3-Way Stainless Steel Ball Valve

Stainless steel 3-way ball valves offer superior corrosion resistance and are well-suited for applications involving aggressive chemicals, high temperatures, and harsh environmental conditions. They are commonly used in the pharmaceutical, food and beverage, and petrochemical industries. The hygienic properties of stainless steel make these valves an excellent choice for sanitary applications where cleanliness is paramount.

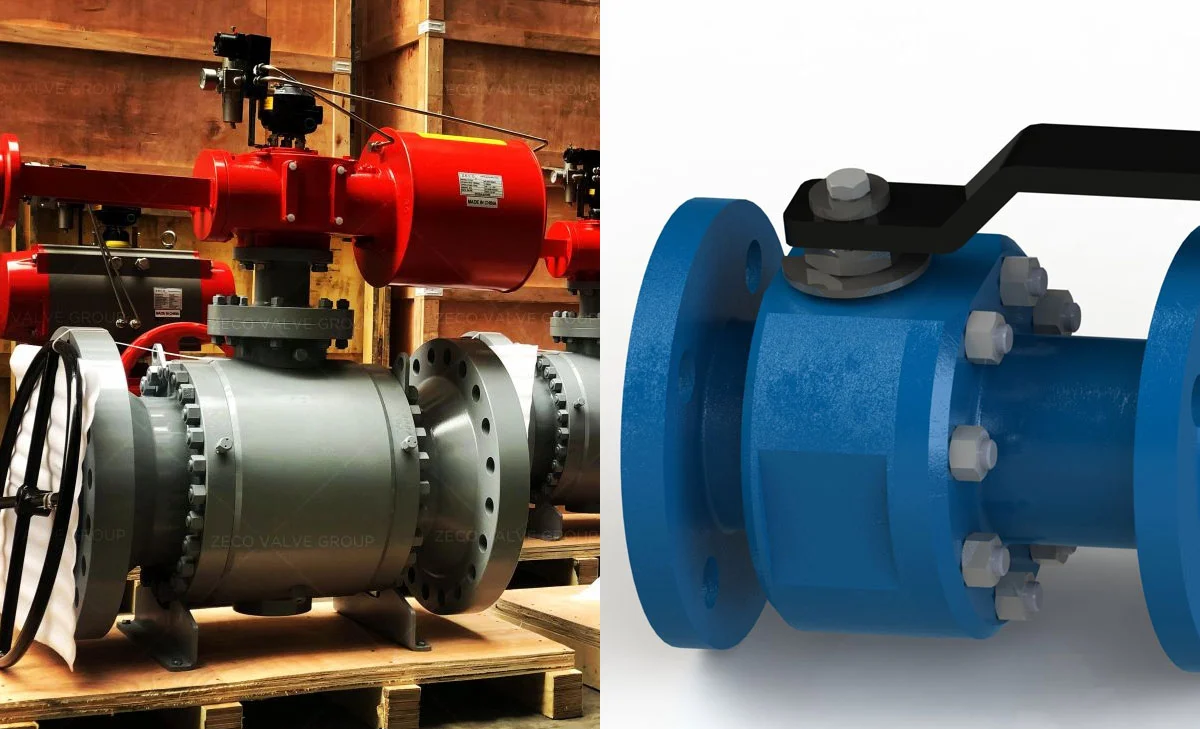

3-Way Electric Ball Valve

Electrically actuated 3-way ball valves provide precise flow control and automation capabilities. These valves are equipped with electric actuators, allowing for remote operation and integration with control systems. They are commonly used in HVAC systems, water treatment plants, and industrial processes where automated flow control is essential. The ability to modulate flow with precision makes electric ball valves an efficient choice for demanding applications.

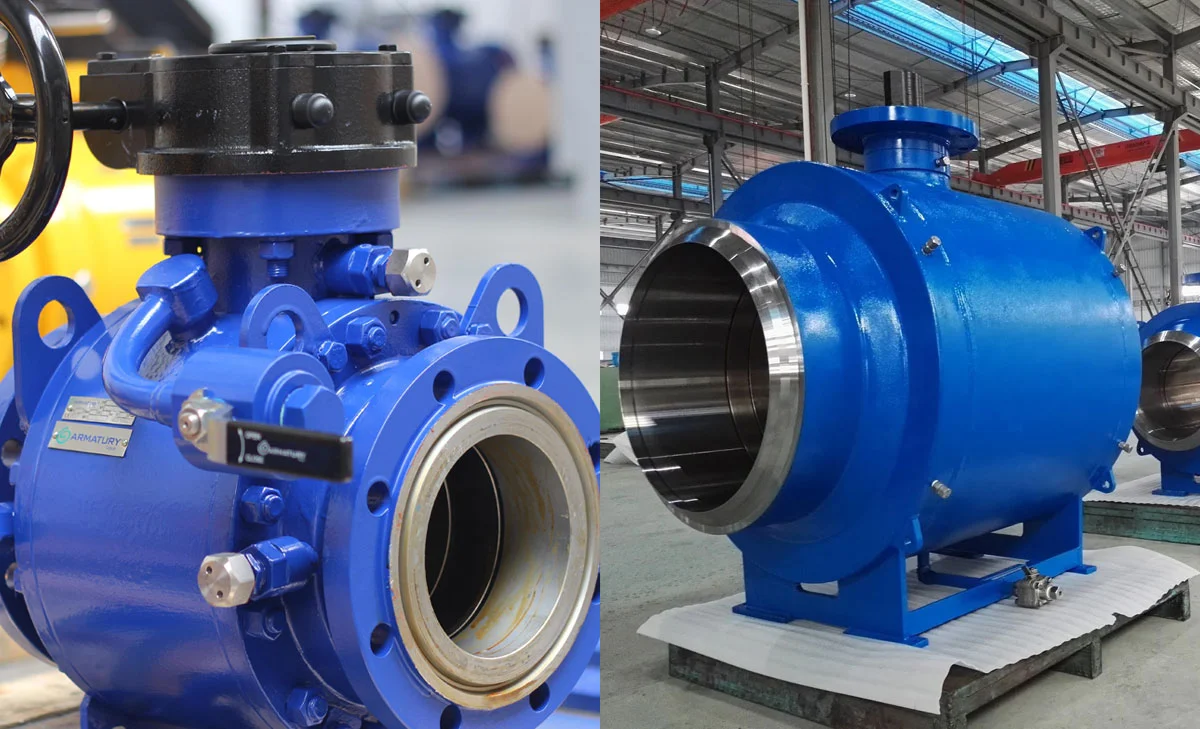

3-Way Flanged Ball Valve

Flanged 3-way ball valves are designed for easy installation and maintenance. The flanged connections facilitate secure attachment to piping systems without the need for additional hardware. These valves are commonly used in petrochemical plants, refineries, and oil and gas pipelines. The robust construction and leak-tight sealing of flanged ball valves make them suitable for high-pressure and high-temperature applications.

In conclusion, the selection of a 3-way ball valve should be based on the specific requirements of the application, including the nature of the fluid, operating conditions, and system design. Understanding the unique characteristics and capabilities of each type of 3-way ball valve is essential for making informed decisions. Whether you’re seeking cost-effective solutions, high-performance capabilities, or automation features, there is a 3-way ball valve to meet your needs. By considering the information provided in this guide, you can confidently choose the most suitable 3-way ball valve for your application.

Key Features and Advantages

3-way ball valves boast a range of key features and advantages that make them indispensable in various industries. Let’s delve into the exceptional traits that set these valves apart.

Versatility in Flow Control

The versatility of 3-way ball valves lies in their ability to divert, mix, or shut off flow, catering to the dynamic requirements of diverse industries. By seamlessly adjusting the direction of flow, these valves play a crucial role in optimizing fluid management in applications such as gas pipelines, oil pipelines, chemical engineering, and industrial processes. Their adaptability empowers engineers and operators to efficiently regulate fluid movement, enhancing system performance while minimizing operational complexities.

Material Variations and Compatibility

3-way ball valves are constructed using a spectrum of materials, including stainless steel, brass, and PVC, to name a few. This broad array of options allows for compatibility with various fluids and operating environments, ensuring optimal performance and longevity. Their corrosion resistance and durability make them suitable for handling aggressive media and demanding conditions, adding a layer of reliability to fluid control systems across different sectors.

Actuation and Automation Options

The integration of electric or pneumatic actuators enhances the operational capabilities of 3-way ball valves, offering advanced control and automation possibilities. From manual operation to seamless integration with modern control systems, the adaptability of these valves paves the way for precision and efficiency. This flexibility not only simplifies system maintenance but also aligns with the evolving automation trends, providing a seamless transition towards smart fluid management solutions.

By encompassing these remarkable features and advantages, 3-way ball valves emerge as indispensable components that contribute to the seamless and effective regulation of fluid flow, catering to the ever-evolving needs of diverse industries.

Choosing the Right 3-Way Ball Valve

When choosing the right 3-way ball valve, it’s crucial to consider the specific application requirements and the maintenance aspects for ensuring optimal performance and longevity.

Considerations for Specific Applications

Selecting the appropriate 3-way ball valve involves considering several factors tailored to the specific application. These factors may include the pressure rating, flow requirements, and environmental conditions.

It’s essential to assess the pressure rating of the 3-way ball valve to ensure it can effectively handle the operating pressure of the system. Understanding the flow requirements will guide the selection process, as different valve designs cater to distinct flow patterns. Additionally, taking into account environmental conditions such as temperature variations and corrosive elements is vital for choosing materials that can withstand these conditions.

Maintenance and Longevity

Maintenance plays a crucial role in the longevity and performance of 3-way ball valves. Regular maintenance routines, including inspection, lubrication, and cleaning, can ensure the smooth operation of the valves over time. Proper installation is also paramount for maximizing the longevity of 3-way ball valves, as it can prevent issues such as leakage and premature wear.

By prioritizing regular maintenance and adhering to proper installation practices, the lifespan of 3-way ball valves can be significantly extended, ultimately contributing to the efficiency and reliability of the overall system.

In summary, the selection of the right 3-way ball valve involves a comprehensive evaluation of application-specific factors, coupled with a focus on regular maintenance and proper installation to ensure sustained performance and longevity.

Installation and Operational Best Practices

Before you delve into the installation and operational aspects of 3-way ball valves, it’s essential to understand the best practices to ensure optimal functionality and safety. By following proper mounting and positioning guidelines and adhering to operating principles, you can guarantee efficient performance and mitigate potential risks.

Proper Mounting and Positioning

When mounting 3-way ball valves, prioritize proper positioning to facilitate optimal fluid flow control. Begin by identifying the directional arrow indicated on the valve body, which signifies the intended flow path. Ensure that the valve is mounted in alignment with the piping system, maintaining the directional orientation as specified by the manufacturer.

Equally important is the orientation of the valve stem. Mount the valve with the stem facing upwards to prevent potential leakage and ensure fluid containment. This positioning also aids in easy access for maintenance and operational adjustments.

Operating Guidelines and Safety Measures

Operating a 3-way ball valve necessitates adherence to standardized procedures and safety measures to guarantee smooth functionality and prevent operational hazards. Prior to usage, verify the compatibility of the valve with the service fluids, taking into account the pressure and temperature ratings.

Emphasize the importance of selecting the appropriate valve sizes based on the application requirements and evaluating the physical and chemical properties of the service fluids. Abiding by these considerations ensures compatibility and minimizes the risk of system inefficiencies or material degradation.

To maintain safety during operations, educate personnel on the proper handling and manipulation of 3-way ball valves, emphasizing the significance of leak-free connections and the avoidance of abrupt pressure transitions. Prioritize regular inspections and testing to promptly identify any potential issues and address them before they escalate, enhancing overall safety and operational reliability.

By adhering to these mounting and operational best practices, you can ensure the effective functionality and safety of 3-way ball valves within diverse applications, promoting efficient fluid control and system integrity.

Top 5 Famous Brands of 3-Way Ball Valves

When it comes to 3-way ball valves, choosing the right brand is crucial for ensuring optimal performance and long-term reliability. In this listicle, we’ll delve into the top 5 famous brands of 3-way ball valves, providing detailed information about each brand’s offerings and why they stand out in the industry.

- Valworx 3-Way Valve Valworx is a renowned brand in the world of industrial valves, and their 3-way ball valves are no exception. Known for their precision engineering and durable construction, Valworx 3-way ball valves are designed to handle a wide range of applications, from general purpose to more specialized uses. With a focus on ease of installation and maintenance, these valves are a popular choice among engineers and maintenance professionals.

- Banjo 3-Way Valve Banjo’s line of 3-way ball valves is widely recognized for its reliability and versatility. These valves are engineered to deliver exceptional performance in agricultural, chemical, and industrial applications. With a focus on corrosion resistance and seamless operation, Banjo 3-way valves are trusted for their ability to handle challenging fluid control tasks with ease.

- Swagelok 3-Way Valve Swagelok is synonymous with quality and innovation in the fluid system industry, and their 3-way ball valves uphold this reputation. Designed for high-pressure and high-temperature environments, Swagelok’s 3-way valves offer robust performance and exceptional leak-tightness. Whether in research facilities, petrochemical plants, or semiconductor manufacturing, Swagelok valves are relied upon for their precision and durability.

- Apollo 3-Way Ball Valve Apollo is a leading provider of fluid control solutions, and their range of 3-way ball valves is widely favored for its durability and performance. Built to withstand demanding conditions, Apollo’s 3-way ball valves excel in applications where reliability and safety are paramount. With a focus on compliance with industry standards and regulations, these valves offer peace of mind in critical fluid handling operations.

- NIBCO 3-Way Ball Valve NIBCO has earned a reputation for excellence in valve manufacturing, and their 3-way ball valves exemplify this commitment to quality. Engineered for precise flow control and minimal pressure drop, NIBCO’s 3-way valves cater to a diverse array of industries, including HVAC, chemical processing, and water treatment. With a focus on longevity and efficiency, NIBCO 3-way ball valves are a go-to choice for demanding fluid handling applications.

Selecting the right brand of 3-way ball valve is paramount for ensuring operational efficiency and reliability. By exploring the offerings of renowned brands such as Valworx, Banjo, Swagelok, Apollo, and NIBCO, engineers and industry professionals can make informed decisions that align with their specific application requirements. Each brand’s commitment to quality, performance, and durability sets them apart in the realm of 3-way ball valves, catering to a wide spectrum of industrial and commercial needs.

Conclusion

Three-way ball valves play a crucial role in fluid control systems due to their versatility and numerous advantages. These valves have proven to be essential in various industries, including manufacturing, oil and gas, chemical processing, and more. The ability to direct the flow of a liquid or gas in different directions offers a multifaceted solution for complex piping systems.

With their L-Port and T-Port configurations, three-way ball valves provide flexibility in regulating flow patterns, allowing for diverter or mixing functions based on specific application requirements. This adaptability makes them a preferred choice for applications where fluid control and direction are paramount. Three-way ball valves have demonstrated efficiency in systems that require the redirection of fluid, isolating different components, or ensuring smooth flow transitions.

Furthermore, the durable construction and reliable operation of three-way ball valves contribute to their widespread usage. Their capacity to handle high pressure and temperature conditions make them suitable for demanding environments. Additionally, their compatibility with various fluids, including corrosive and abrasive media, increases their applicability in diverse settings.

In summary, three-way ball valves hold significant importance in fluid control systems, offering a blend of reliability, adaptability, and durability. Their multifaceted nature makes them an indispensable component in managing fluid flow in numerous industrial processes, making them a valuable asset across different sectors.