Stainless Steel Ball Valves: Top 10 Industries that Benefit

Table of Contents

ToggleTop 10 Industries Benefiting from Stainless Steel Ball Valves

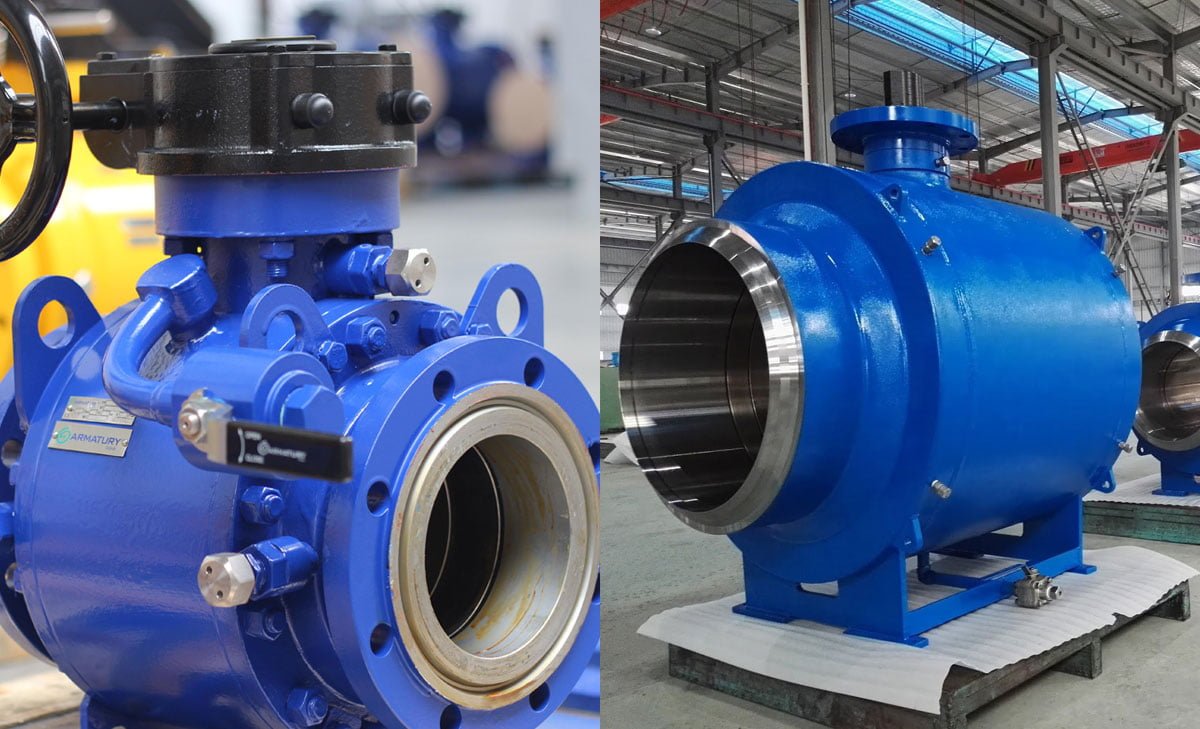

Stainless steel ball valves are essential components in various industries, ensuring efficiency, safety, and reliability in heavy-duty systems. From maintaining clean water to meeting the demands of energy production, these valves play a crucial role. In this blog post, we will explore the top 10 industries that benefit from the use of stainless steel ball valves, highlighting their significance and impact across different sectors. Whether it’s for controlling flow in chemical processing or regulating water supply in municipal applications, stainless steel ball valves are indispensable in numerous industrial settings.

The Essential Role of Stainless Steel Ball Valves in Various Industries

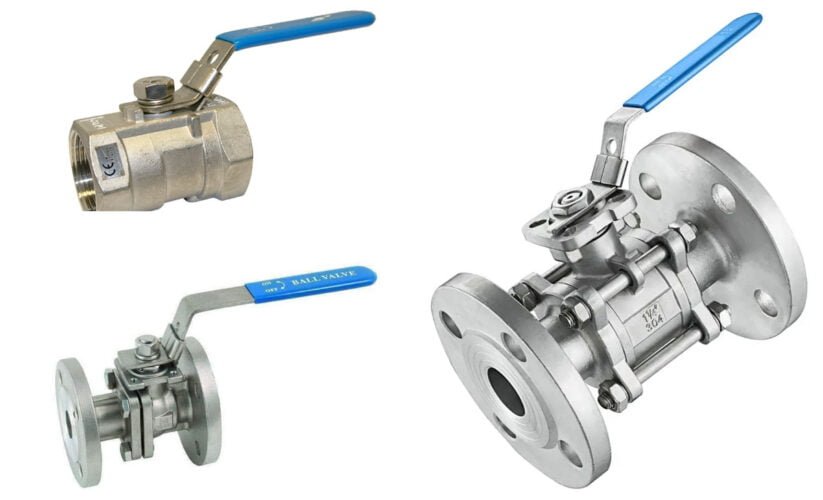

More Corrosion Resistant

Stainless Steel Ball Valves offer superior corrosion resistance compared to brass, making them ideal for various industries. Corrosion can compromise the functionality of valves, and stainless steel’s resilience ensures longevity even in harsh water conditions. The two main types of stainless steel, 304 and 316, provide different levels of corrosion resistance. The 316 grade, containing molybdenum, offers even greater protection against corrosion, making it suitable for demanding industrial environments.

Pressure Ratings

Stainless Steel Ball Valves boast higher pressure ratings than brass counterparts. This makes them well-suited for commercial, industrial, and water well applications that require the handling of higher pressure levels. For instance, a standard 1” brass ball valve may have a pressure rating of 600 PSI, while a comparable stainless steel ball valve could offer a higher rating of 1000 PSI, ensuring reliable performance under pressure.

Wider Range of Applications

The versatility of stainless steel enables its use across a wide range of applications, from conventional plumbing to industrial and commercial settings. The rise of No-Lead Brass pricing has further propelled the popularity of stainless steel in plumbing applications. Its competitive pricing and superior performance make stainless steel ball valves a preferred choice in various industries, catering to diverse needs with efficiency and reliability.

Oil and Gas Industry: The Backbone of Energy Production

Ensuring Safety and Efficiency in High-Pressure Environments

The oil and gas industry relies heavily on stainless steel ball valves to ensure safety and efficiency in high-pressure environments. These valves are crucial for controlling the flow of various substances in the production, refining, and transportation processes. The high-pressure nature of these operations requires durable and reliable valves to maintain operational integrity. Stainless steel ball valves are engineered to withstand extreme pressure, making them an indispensable component in oil and gas operations.

Withstanding Corrosive Substances and Extreme Temperatures

Stainless steel ball valves play a vital role in the oil and gas industry by withstanding highly corrosive substances and extreme temperatures. The harsh conditions within oil wells, pipelines, and refineries demand materials that can resist corrosion and maintain structural integrity. Stainless steel’s inherent resistance to corrosion, coupled with its ability to withstand extreme temperatures, makes it an ideal choice for ball valves in the oil and gas sector. This ensures that the valves can perform reliably and maintain operational safety even in the most challenging environments.

Water Treatment and Distribution: Maintaining Quality and Flow

Resistance to Contamination and Corrosion

Stainless steel ball valves play a crucial role in safeguarding water quality in the treatment and distribution process. The inherent resistance to corrosion and contamination makes them an ideal choice for ensuring that potable water remains pure and unpolluted. Unlike other materials, stainless steel ball valves are not prone to rust, pitting, or scaling, offering a reliable and long-lasting solution for maintaining the integrity of water as it goes through various treatment stages and into the distribution network.

Managing High-Volume Water Systems

In the realm of water treatment and distribution, the need to manage high-volume water systems is a common challenge. Stainless steel ball valves are designed to handle the demands of such systems, offering robustness and reliability in controlling the flow of water at varying pressures and volumes. Their durable construction and efficient flow control make them essential components in large-scale treatment facilities and extensive distribution networks, ensuring seamless and effective management of high water volumes without compromising on quality.

Chemical Processing: Precision and Purity in Production

Controlling Aggressive Chemical Flows

Stainless steel ball valves play a crucial role in chemical processing, ensuring the precision and purity of production. These valves are designed to withstand aggressive chemical flows, providing an essential control mechanism in chemical plants and manufacturing facilities. The exceptional durability and corrosion resistance of stainless steel make it an ideal material for handling harsh chemicals. This ensures that the valves maintain their integrity and functionality over extended periods, contributing to the safety and efficiency of chemical processing operations.

Avoiding Cross-Contamination with Reliable Seals

In the realm of chemical processing, cross-contamination can have detrimental effects on product quality and safety. Stainless steel ball valves are equipped with reliable seals that effectively prevent the mixing of different chemicals, maintaining the purity of the production process. This feature is essential for ensuring compliance with stringent industry standards and regulations governing the handling and processing of chemicals. By leveraging the precision engineering and robust sealing capabilities of stainless steel ball valves, chemical processing facilities can uphold the highest standards of product purity and integrity.

Pharmaceuticals: Guaranteeing Sterility and Precision

Cleanliness in Sensitive Manufacturing Processes

In pharmaceutical manufacturing, maintaining cleanliness and sterility is crucial to ensure the safety and efficacy of medicinal products. Stainless steel ball valves play a vital role in this aspect by providing a hygienic and corrosion-resistant solution for controlling the flow of liquids and gases. The smooth, non-reactive surface of stainless steel prevents contamination and ensures that the pharmaceutical products remain untainted by the materials used in the valves.

Stainless steel ball valves are designed to minimize bacterial and particulate buildup, making them ideal for applications that demand stringent cleanliness standards. Their smooth internal surfaces and minimal dead space design make them easy to clean and sterilize, reducing the risk of cross-contamination and ensuring the purity of pharmaceutical products.

Meeting Strict Regulatory Standards

The pharmaceutical industry is highly regulated, with strict guidelines in place to ensure the safety, quality, and efficacy of drugs and medical devices. Stainless steel ball valves comply with these stringent regulatory standards, making them an essential component in pharmaceutical manufacturing processes.

By using stainless steel ball valves, pharmaceutical companies can demonstrate their commitment to adhering to Good Manufacturing Practices (GMP) and other regulatory requirements. These valves are designed to meet the industry’s demanding specifications, providing reliability and precision in controlling critical processes while upholding the highest levels of sterility and quality assurance.

With the ability to ensure cleanliness in sensitive manufacturing processes and meet strict regulatory standards, stainless steel ball valves are indispensable in the pharmaceutical industry, contributing to the production of safe and effective medications.

Food and Beverage Industry: Ensuring Sanitary Processing

The food and beverage industry relies on stainless steel ball valves to uphold the highest standards of quality and safety in the production process. Stainless steel ball valves play a crucial role in maintaining sanitary conditions, ensuring the taste and safety of food production, and providing ease of cleaning and maintenance for hygiene control.

Maintaining Taste and Safety in Food Production

Stainless steel ball valves are essential in ensuring the taste and safety of food production. They are constructed to be corrosion-resistant, preventing any contamination that could compromise the quality and safety of food and beverage products. The non-reactive nature of stainless steel preserves the integrity of the products, making it the ideal material for handling food and beverages.

Easy Cleaning and Maintenance for Hygiene Control

The ease of cleaning and maintenance offered by stainless steel ball valves is paramount for maintaining hygiene control in the food and beverage industry. The smooth and non-porous surface of stainless steel makes it easy to clean and sanitize, reducing the risk of bacterial growth and contamination. This inherent cleanliness makes stainless steel ball valves the top choice for applications requiring strict hygiene standards, ensuring the purity of the end products.

Stainless steel ball valves are indispensable in upholding sanitary processing standards in the food and beverage industry, safeguarding the quality and safety of the products while facilitating efficient cleaning and maintenance practices to ensure unparalleled hygiene control.

Marine Applications: Durability in Harsh Sea Conditions

Saltwater corrosion poses significant challenges in marine applications. Stainless steel ball valves are specifically engineered to combat these harsh conditions, making them indispensable in various marine industries.

Combating Saltwater Corrosion

Stainless steel ball valves are crafted to withstand the corrosive effects of saltwater. The high corrosion resistance of stainless steel, particularly alloys such as 316 or 316L, ensures that the ball valves can endure prolonged exposure to saltwater without compromising their integrity. This resistance significantly reduces maintenance and replacement costs, making stainless steel ball valves a cost-effective solution for marine applications.

Ball Valves in Shipbuilding and Offshore Platforms

In shipbuilding, the reliability and durability of stainless steel ball valves are crucial during the construction of vessels. These valves are used in various systems onboard, including seawater cooling, ballast, and fuel systems. Moreover, in offshore platforms, where exposure to saltwater and harsh environmental conditions is constant, stainless steel ball valves play a vital role in regulating fluid flow with minimal risk of corrosion-related failures. Their robust construction and resistance to corrosion make them an ideal choice for ensuring operational safety and efficiency in offshore installations.

Pulp and Paper Manufacturing: Streamlining Production

The pulp and paper manufacturing industry plays a vital role in producing a wide array of paper products used in packaging, printing, and personal care. With the global paper production capacity projected to reach 510 million tons by 2025, the industry faces the challenge of meeting this rising demand while also streamlining its production processes.

Handling Fibrous and Corrosive Fluids

One of the critical aspects of the pulp and paper manufacturing process is the handling of fibrous and corrosive fluids. Stainless steel ball valves play a crucial role in managing these fluids effectively. The resistance of stainless steel to corrosion ensures the integrity and longevity of the valves, even when dealing with aggressive chemicals and abrasive fibrous materials. This capability enhances the reliability of the manufacturing process and minimizes the risk of downtime due to equipment failure.

Improving Process Reliability and Efficiency

By incorporating stainless steel ball valves, the paper manufacturing process can significantly improve its reliability and efficiency. These valves provide tight shut-off capabilities, ensuring precise control over the flow of fluids throughout the production process. The robust construction of stainless steel ball valves also enhances their ability to withstand the demanding conditions present in pulp and paper manufacturing facilities. As a result, these valves contribute to the overall productivity and cost-effectiveness of the manufacturing process, offering a durable solution for fluid control in this industry.

Role in Solar Thermal Systems

Stainless steel ball valves offer significant benefits within solar thermal systems. Their corrosion resistance and durability make them ideal for the demanding conditions present in these systems. Stainless steel ball valves effectively control the flow of heat transfer fluids, ensuring optimal performance and efficiency in capturing solar energy.

Geothermal Energy

In the realm of geothermal energy, stainless steel ball valves play a crucial role in regulating the flow of geothermal fluids. These valves are capable of withstanding the high temperatures and corrosive nature of geothermal fluids, contributing to the effective and safe operation of geothermal energy systems.

Use of Stainless Steel Ball Valves

Stainless steel ball valves are instrumental in promoting the efficiency and reliability of renewable energy production. Whether it’s facilitating the flow of heat transfer fluids in solar thermal systems or handling the unique demands of geothermal energy, these valves contribute to the seamless operation of renewable energy processes, ultimately advancing the sustainability of energy production.

Aerospace and Defense: High Standards for Critical Applications

Meeting the Demand for Precision and Reliability

In the aerospace and defense industries, precision and reliability are non-negotiable. Stainless steel ball valves play a crucial role in meeting the demand for precision and reliability. These industries rely on valves that can consistently deliver accurate and dependable performance to ensure the safety and efficiency of critical applications. With their ability to control flow and pressure with precision, stainless steel ball valves are essential components in aircraft and defense systems.

Withstanding Extreme Conditions and Temperatures

Aerospace and defense applications often operate in extreme conditions and temperatures. Stainless steel ball valves are designed to withstand such challenging environments, making them the ideal choice for critical applications in these industries. Whether it’s the high pressures and temperatures of aircraft hydraulic systems or the harsh conditions of military equipment, stainless steel ball valves are engineered to maintain their integrity and functionality, providing the necessary durability and resilience.

By incorporating stainless steel ball valves into their systems, the aerospace and defense industries can ensure the seamless operation of critical applications, even in the face of adverse conditions and temperatures.

Construction and Infrastructure: The Foundation of Modern Development

Civil engineering is a vital field that shapes the construction and infrastructure landscape, playing a pivotal role in the development of modern society. From controlling water supply and HVAC systems to ensuring the longevity and dependability of public works, civil engineers are instrumental in shaping our surroundings in ways that optimize efficiency, safety, and sustainability.

Controlling Water Supply and HVAC Systems

Civil engineers are indispensable in the design and construction of water supply systems that cater to the demands of growing populations. They ensure the efficient delivery of clean water to homes and businesses, contributing to public health and sanitation. Additionally, their expertise extends to the development of Heating, Ventilation, and Air Conditioning (HVAC) systems, which are integral to maintaining comfortable indoor environments in commercial and residential settings.

Longevity and Dependability in Public Works

The impact of civil engineering on public works is profound, as these professionals are dedicated to creating infrastructure that stands the test of time. Whether it’s building robust roadways, bridges, or waste management systems, civil engineers prioritize the durability and reliability of these structures. By meticulously planning and executing these projects, they contribute to the long-term functionality and safety of the communities they serve, fostering sustainable development and progress.

Conclusion

Stainless steel ball valves are essential in various industries, ensuring seamless operations and safety. From energy production to water treatment, these valves play a crucial role in maintaining efficiency and reliability. Choosing a reputable manufacturer like DomBor can provide top-notch valves that meet industry standards, ensuring longevity and performance. With their extensive product range and ISO certification, DomBor is dedicated to delivering high-quality valves tailored to diverse industrial needs. When it comes to securing the right ball valves, partnering with a trusted distributor like DomBor ensures that every job, no matter how demanding, is handled with precision and excellence.