The Crucial Role of Gate Valves in Water Treatment Plant Safety

Table of Contents

ToggleUnderstanding the Importance of Gate Valves in Water Treatment Plants

Water treatment plants play a critical role in ensuring the safety and quality of our water supply. The use of the correct valves within these facilities is essential to maintain consistent and effective operation while minimizing the need for maintenance. Gate valves are among the key components in these systems, known for their ability to provide full-stop control of water flow. In this article, we will explore the significant contribution of gate valves to the safety and efficiency of water treatment plants.

The Role of Gate Valves in Water Treatment Safety

Gate valves play a crucial role in ensuring the safety and efficiency of water treatment plants. Understanding the definition and basic function of gate valves, their full-stop capability for system control, and how they compare to other valve types is essential for comprehending their significance.

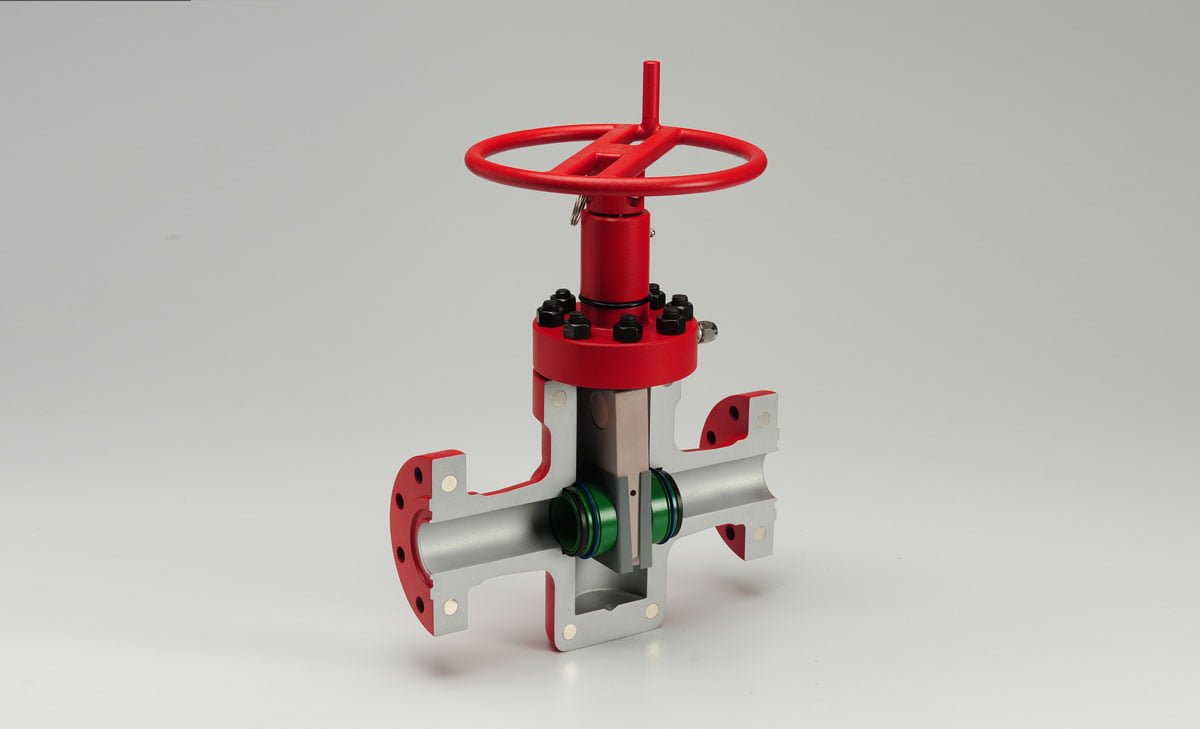

Definition and Basic Function of Gate Valves

Gate valves are classified as full-stop valves, meaning when in the “on” position, the valve is entirely open on the inside, allowing material to flow through freely. Conversely, in the “off” position, the flow of water through the valve is completely cut off by a gate closure within the valve. This design allows gate valves to be positioned either fully open or fully closed, making them unsuitable for adjusting the pressure of water flow. Therefore, they are best suited for applications requiring isolation rather than throttling.

Full-Stop Capability of Gate Valves for System Control

The capability of gate valves to provide a complete seal when closed makes them ideal for usage in systems with high pressures and temperatures. They are commonly utilized in manufacturing, pharmaceutical, gas and oil, as well as automotive and marine systems. While smaller gate valves may offer cost-effective solutions, larger ones can be relatively expensive. Their effectiveness in high-pressure systems and their full-stop functionality contribute significantly to the safety and control of water treatment plants.

Gate Valves Versus Other Valve Types

Compared to other valve types commonly used in water treatment, gate valves are distinct in their full-stop functionality. Unlike butterfly valves, which are used to isolate or regulate flow, gate valves are designed for on/off operation, offering a high level of shut-off capability. Check valves, on the other hand, are designed to prevent backflow and are not suitable for applications requiring the complete cessation of flow. The unique circular closure component of ball valves allows for quick open or close with a quarter turn but differs from the full-stop functionality of gate valves.

Understanding the role of gate valves in water treatment safety entails recognizing their full-stop capability, their suitability for system control in high-pressure environments, and their differentiation from other valve types commonly used in the industry. This understanding is vital for ensuring the efficient and secure operation of water treatment facilities.

Ensuring Reliable Water Flow Management

How Gate Valves Handle High Pressure and Temperature

In water treatment plants, gate valves play a crucial role in managing and controlling water flow. These valves are designed to handle high pressure and temperature, ensuring reliable performance in demanding environments. The sturdy construction of gate valves, with their robust metal components, allows them to withstand the immense pressure and temperature variations typically encountered in water treatment operations.

Gate Valves in Emergency Situations

During emergency situations, such as sudden surges or system shutdowns, gate valves provide a reliable means of controlling and isolating the water flow. Their swift and precise operation enables plant operators to respond effectively to unexpected events, thereby contributing to the overall safety and stability of the water treatment process. Gate valves serve as a critical component in managing water flow, particularly in emergency scenarios, providing assurance of swift and effective response capabilities.

Maintenance and Durability Concerns

The Wear and Tear of Improper Usage

Gate valves in water treatment plants are crucial components that require regular maintenance to ensure optimal performance. Improper usage can lead to significant wear and tear, affecting the functionality of the valves. Factors such as excessive force during operation, exposure to harsh chemicals, and lack of routine inspections can contribute to accelerated deterioration. This emphasizes the importance of following proper operating procedures and conducting regular maintenance checks to mitigate potential damage.

Longevity and Cost-Effectiveness of Gate Valves

When properly maintained, gate valves exhibit impressive longevity and cost-effectiveness. Their robust construction and durable materials enable them to withstand prolonged usage in demanding environments. This durability translates to fewer replacements and repairs, resulting in cost savings for water treatment facilities over the long term. Additionally, the extended lifespan of gate valves contributes to overall operational efficiency and reliability, reinforcing their significance in ensuring the safety and effectiveness of water treatment processes.

Installation and Operational Standards

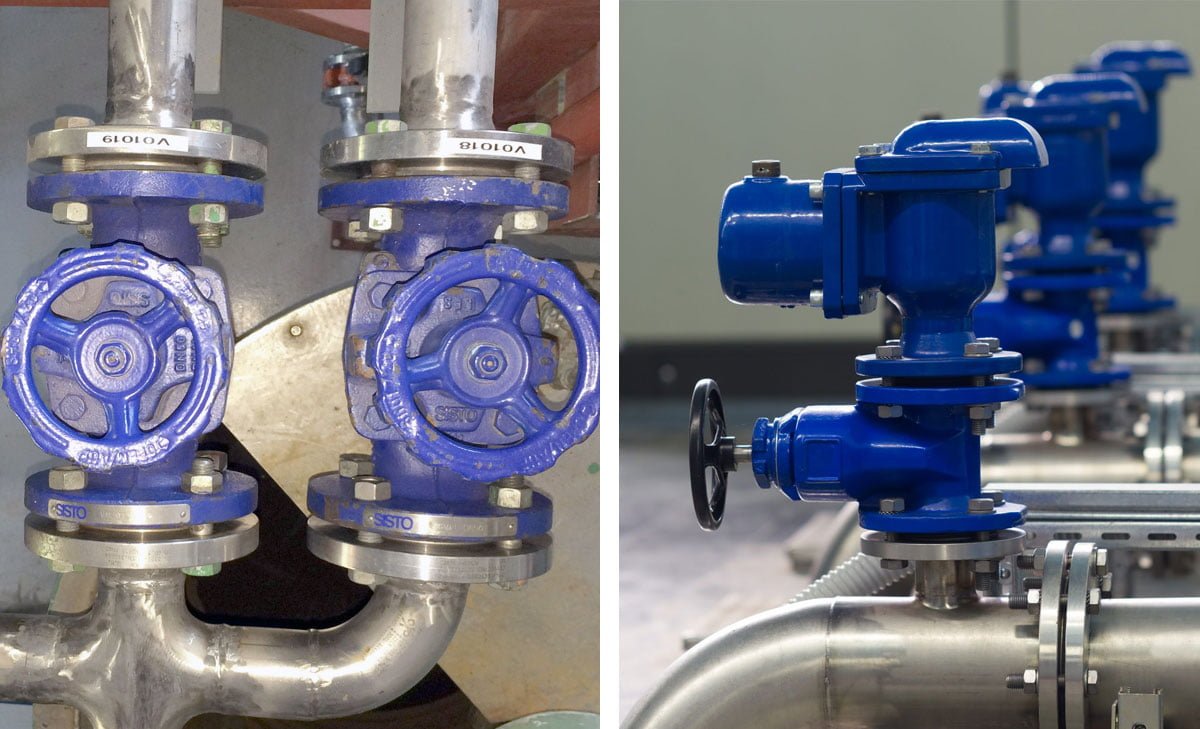

When it comes to the safety and efficiency of water treatment plants, the installation and operational standards for gate valves play a crucial role. Proper sizing and placement of gate valves within treatment plants are essential to ensure optimal functionality. Gate valves should be strategically sized and placed to control the flow of water effectively within the treatment process. Additionally, staff training for gate valve operation is vital to ensure that personnel are equipped with the knowledge and skills to operate the valves efficiently.

Proper Sizing and Placement in Treatment Plants

Gate valves must be sized appropriately according to the specific requirements of the water treatment plant. The correct sizing ensures that the valves can handle the expected flow rates and pressure conditions within the system. Moreover, the placement of gate valves at key points in the treatment process is critical for regulating the flow of water and controlling the overall operation of the plant. By strategically situating gate valves, water treatment facilities can optimize their processes and maintain the safety and reliability of their operations.

Staff Training for Gate Valve Operation

Staff members involved in the operation and maintenance of water treatment plants should undergo comprehensive training in gate valve operation. Training programs should cover various aspects, including valve functionality, troubleshooting common issues, and implementing routine maintenance procedures. Equipping personnel with the necessary knowledge and practical skills ensures that gate valves are operated correctly, contributing to the overall safety and effectiveness of the treatment plant.

By adhering to proper installation and operational standards for gate valves, water treatment plants can enhance their safety protocols and operational efficiency, ultimately contributing to the delivery of clean and safe drinking water to communities.

Advantages of Gate Valves in Water Treatment Plants

The implementation of gate valves in water treatment plants offers various advantages, contributing significantly to the overall efficiency and longevity of the system. Below are the key benefits:

Energy Efficiency and Reduced Water Loss

Gate valves support the energy efficiency of water treatment plants by providing a full, unobstructed flow path when fully open. This unrestricted flow reduces the energy required to push water through the system, promoting efficiency and minimizing operational costs. Additionally, gate valves are adept at controlling the flow, effectively minimizing water loss and leakage. The ability to completely seal off the flow of water when closed ensures that the plant operates with minimal wastage, ultimately contributing to conservation efforts and cost savings.

Contribution to System Longevity

Gate valves play a pivotal role in enhancing the longevity of water treatment systems. By effectively controlling the flow of water, these valves help regulate pressure, reducing the likelihood of sudden pressure surges that can lead to system wear and damage. The ability to isolate sections of the system for maintenance or repairs without disrupting the entire operation further extends the lifespan of the treatment plant. In essence, gate valves offer a safeguard against premature system deterioration, reinforcing the reliability and durability of the infrastructure.

The implementation of gate valves in water treatment plants presents a compelling value proposition, combining energy efficiency, reduced water loss, and enhanced system longevity.

Challenges and Solutions for Gate Valve Use

Gate valves play a crucial role in ensuring the safety and efficiency of water treatment plants. However, their application comes with several challenges that need to be addressed to maintain optimal functionality and reliability.

Common Obstacles in Gate Valve Application

- Corrosion: One of the primary challenges in gate valve application is the potential for corrosion due to the exposure to water and chemicals in the treatment process. This can lead to deterioration of valve components, ultimately impacting performance and safety. Regular inspections and the use of corrosion-resistant materials can help mitigate this issue.

- Scaling and Sediment Buildup: In water treatment plants, gate valves are susceptible to scaling and sediment buildup, particularly in areas with hard water. This accumulation can impede the smooth operation of the valve, leading to restricted flow and potential malfunction. Implementing proper filtration systems and periodic maintenance can address this challenge effectively.

- Pressure Fluctuations: Gate valves may encounter pressure variations within the water treatment system, which can exert significant stress on the valve components. This can result in leakage or valve damage if not managed appropriately. Proper sizing, installation of pressure relief valves, and regular monitoring are essential to mitigate the impact of pressure fluctuations.

Addressing Gate Valve Limitations in Water Treatment

- Enhanced Material Selection: To address the issue of corrosion, selecting gate valves constructed from corrosion-resistant materials such as stainless steel or bronze can significantly extend their service life and minimize the effects of chemical exposure.

- Improved Maintenance Practices: Implementing proactive maintenance schedules, including regular cleaning to remove scaling and sediment buildup, can help preserve the operational efficiency of gate valves in water treatment plants.

- Pressure Management Systems: Integrating pressure management systems into the water treatment infrastructure can effectively regulate pressure fluctuations, safeguarding gate valves from potential damage and ensuring consistent performance.

By proactively addressing these challenges and implementing suitable solutions, water treatment plants can optimize the functionality of gate valves, thereby contributing to the overall safety and reliability of the treatment processes.

Conclusion

In conclusion, gate valves play a crucial role in ensuring the safety and efficiency of water treatment plants. These valves are designed to provide full-stop control, allowing for unrestricted flow in the open position and complete shutoff when closed. Their ability to withstand high temperatures and pressures makes them ideal for various water treatment applications, including within manufacturing, pharmaceutical, gas and oil, automotive, and marine systems. By utilizing gate valves in water treatment facilities, operators can maintain consistent and reliable operation while minimizing the risk of damage and the need for excessive maintenance.