The Ultimate Guide to Gate Valves for Water Systems

Table of Contents

ToggleIntroduction to Usage of Gate Valves for Water

Gate valves are essential components in water systems, regulating the flow of water with precision and reliability. In this blog post, we will delve into the functions and benefits of gate valves for water, exploring their design, applications, and advantages in various water management systems. Understanding the role of gate valves is crucial for ensuring efficient and safe water distribution and control.

Understanding Gate Valves and Their Importance in Water Control

Water gate valves are essential for regulating water flow in various commercial and residential water systems. Understanding the basics of gate valve operation, the key components of a gate valve, and why gate valves are crucial for water systems is fundamental to their effective use.

Basics of Gate Valve Operation

Gate valves are multi-turn valves that control the flow of water. The valve’s handwheel needs to turn more than 360° to fully open or close the valve. The handle turns clockwise to close the valve, and when opening, it should stop turning when resistance is felt. The stem can be rising or non-rising, indicating whether it rises out of the valve body when the valve opens or not. Gate valves can also be actuated using pneumatic, hydraulic, and electric methods.

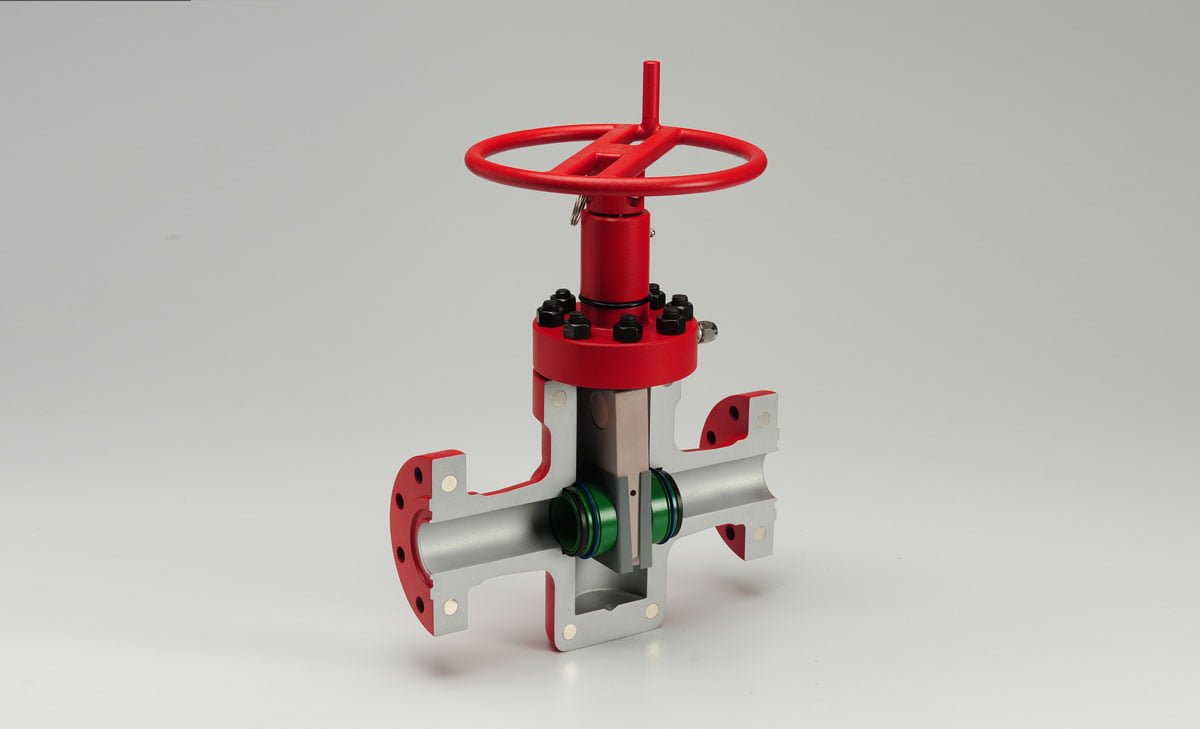

Key Components of a Gate Valve

The gate valve consists of essential components such as the gate, valve body, bonnet, and gasket. When the gate valve is open, water can flow through it unimpeded with minimal pressure drop. However, it is important to note that gate valves are not suitable for modulating or throttling flow.

Why Gate Valves Are Essential for Water Systems

Gate valves play a crucial role in water systems as they help in effectively controlling the flow of water. Their ability to completely block water flow when closed and allow unrestricted flow when open makes them indispensable in water control applications. Additionally, the valve body and bonnet protect the inner mechanisms from outside elements and help prevent leaking, ensuring efficient water system operations.

Understanding the operational principles and components of gate valves is vital for their proper use in water systems. With their ability to regulate water flow effectively, gate valves are indispensable for ensuring optimal functionality and control in water systems.

Types of Gate Valves for Water Supply

Gate valves are imperative components in water supply systems, facilitating the control and regulation of water flow. These valves come in various types, each tailored for specific applications and functionality.

Solid Wedge Gate Valves

Solid wedge gate valves feature a solid piece of wedge that ensures a tight seal. This design offers robust performance, making it ideal for demanding water supply systems where a secure shutoff is essential.

Flexible Wedge Gate Valves

In contrast, flexible wedge gate valves are designed to accommodate the structural stresses that can occur during operation. Their flexibility allows them to adapt to changes in temperature and pressure, ensuring reliable performance over time.

Split Wedge or Parallel Disk Gate Valves

Split wedge or parallel disk gate valves are characterized by a parallel, disk-like closing element that fits between two parallel seats. This configuration, including knife gate valves, is well-suited for applications requiring a tight shutoff and minimal pressure drop.

Rising Stem vs. Non-Rising Stem Gate Valves

Gate valves are further categorized by their stem movement, with options for rising and non-rising stems. This distinction influences the valve’s operational dynamics and the space required for installation, offering flexibility to suit diverse system requirements.

Material Choices: Gate Valves for Water Applications

Selecting the right material for gate valves is essential to ensure optimal performance and longevity in water applications. The choice of material depends on factors such as media composition, compatibility with the media, exposure duration, operating pressure, service temperatures, coating effectiveness, and cost considerations.

Cast Iron Gate Valves

Cast iron gate valves are commonly used in water applications due to their durability and corrosion resistance. They are suitable for handling clear or particle-filled water and can withstand varying temperatures. The effectiveness of the coating on cast iron gate valves further enhances their longevity in water environments.

Ductile Iron Gate Valves

Ductile iron gate valves offer similar benefits to cast iron gate valves while providing greater strength and flexibility. These valves are ideal for water systems with high operating pressures and temperatures. The ductile iron construction ensures resistance to corrosion and mechanical stress, making them reliable for long-term use in water applications.

Brass Gate Valves

Brass gate valves are preferred for their excellent corrosion resistance and suitability for potable water systems. The inherent antimicrobial properties of brass make it a hygienic choice for water applications. Additionally, brass gate valves are known for their ease of installation and low friction loss, contributing to efficient water flow control.

Stainless Steel Gate Valves

Stainless steel gate valves are highly resilient to corrosion and chemical damage, making them suitable for a wide range of water applications. They offer exceptional durability, even in aggressive water environments, and are capable of withstanding high temperatures and pressures. The longevity and minimal maintenance requirements of stainless steel gate valves make them a cost-effective choice for water systems.

When selecting a gate valve material for water applications, it’s important to consider the specific requirements of the system to ensure optimal performance, longevity, and cost-effectiveness. Each material offers unique advantages, and understanding their characteristics is crucial in making an informed decision for water system needs.

Advantages of Gate Valves for Water Management

Gate valves for water management systems offer several advantages. They are designed to control the flow of water while minimizing pressure loss, ensuring bidirectional shutting capabilities, and offering exceptional durability within water systems.

Minimal Pressure Loss

Gate valves are known for their ability to provide minimal pressure loss, making them highly efficient for water management. When fully open, gate valves allow unobstructed flow, reducing turbulence and pressure drop. This advantageous feature helps maintain optimal water pressure levels within the system, ensuring consistent and reliable water distribution.

Bidirectional Shutting Capabilities

One of the key advantages of gate valves for water management is their bidirectional shutting capabilities. These valves can effectively stop the flow of water in both directions, providing precise control over the water supply. This bidirectional functionality is essential for managing and regulating water flow in various applications, including pipelines, reservoirs, and distribution networks.

Durability in Water Systems

Gate valves are designed to withstand the demanding conditions of water systems, offering exceptional durability and longevity. Built to resist corrosion and erosion caused by water exposure, these valves provide reliable performance over extended periods. Their robust construction and materials make them suitable for continuous operation in water management infrastructure, ensuring minimal maintenance and uninterrupted functionality.

By leveraging the minimal pressure loss, bidirectional shutting capabilities, and durability of gate valves, water management systems can achieve efficient and reliable operation, contributing to overall system performance and longevity.

Installation Considerations for Water Gate Valves

Proper Sizing and Positioning

When installing gate valves for water systems, it is crucial to ensure the proper sizing and positioning. The valve must be sized according to the flow requirements to prevent inefficiencies or excessive pressure drop. Additionally, positioning the valve in the right location within the pipeline is essential for optimal performance. Proper sizing and positioning contribute to the overall effectiveness of the water distribution system while minimizing potential issues.

Flanged, Threaded, or Welded Connections

Selecting the appropriate connection type is a critical consideration during the installation of water gate valves. Flanged connections offer ease of maintenance and are suitable for larger valve sizes. Threaded connections are convenient for smaller valves and low-pressure applications, while welded connections provide a secure and leak-free option for high-pressure environments. The choice of connection type should align with the specific requirements of the water distribution system.

Orientation and Accessibility for Operation

The orientation of gate valves for water systems plays a significant role in their functionality. Proper orientation ensures that the valve operates efficiently and effectively within the pipeline system. Accessibility for operation is also crucial for maintenance and emergency situations. Placing the valve in an easily accessible location simplifies routine inspections and repairs, contributing to the overall functionality and reliability of the water distribution network.

Operating and Maintaining of Gate Valves for Water

When dealing with water gate valves, routine inspection and maintenance are essential to ensure optimal functionality and longevity. By conducting regular checks and following maintenance best practices, you can prevent operational issues and extend the lifespan of the valves. Here are some key aspects to consider about gate valves for water systems:

Routine Inspection and Maintenance Tips

Regularly inspect the water gate valves for signs of wear, corrosion, or leakage. Ensure that the valves open and close smoothly without any obstructions. Lubricate the moving parts as per the manufacturer’s recommendations to prevent stiffness or seizing. Additionally, perform thorough checks for any buildup of sediments or debris, especially in applications with varying flow rates.

Common Operational Issues and Solutions

One common issue with water gate valves is the failure to close properly. This can often be attributed to sediment buildup inside the valve body, impeding the gate’s movement. To address this, it is essential to flush the system regularly and remove any accumulated sediments. Additionally, inspect the sealing components for damage and replace them if necessary to restore the valve’s proper function.

Lifespan and Replacement Indicators

The lifespan of water gate valves can vary depending on factors such as usage, operating conditions, and maintenance practices. However, signs of wear, persistent leaks, or compromised structural integrity indicate the need for replacement. Regular monitoring of the valves’ performance and condition will help in identifying any indicators that warrant consideration for replacement.

By adhering to these operational and maintenance guidelines, you can ensure the reliable performance of water gate valves and mitigate potential issues that may compromise their functionality.

Gate Valve for Water Standards and Certifications

Gate valves for water systems are essential components that must adhere to specific standards and certifications to ensure their reliability and safety. Understanding these standards and certifications is crucial for anyone involved in the water industry, from engineers to facility managers.

Understanding AWWA Standards for Water Gate Valves

The American Water Works Association (AWWA) sets the standards for gate valves used in water systems. These standards encompass various aspects, including design, materials, and performance requirements. AWWA standards ensure that gate valves are durable, corrosion-resistant, and capable of withstanding the rigors of water system operations. Adhering to AWWA standards is vital for ensuring the longevity and effectiveness of gate valves in water applications.

The Role of NSF/ANSI Standards in Water Safety

NSF International and the American National Standards Institute (ANSI) play a pivotal role in verifying the safety and performance of products used in water treatment and distribution. Gate valves that comply with NSF/ANSI standards have undergone rigorous testing to validate their ability to meet stringent requirements for health and safety. Choosing gate valves certified to NSF/ANSI standards provides assurance that they are suitable for use in potable water systems, contributing to overall water safety and public health.

Importance of ISO Certification for Gate Valves

ISO certification signifies that a manufacturer’s quality management system meets international standards. Gate valve manufacturers with ISO certification demonstrate their commitment to producing reliable and consistent products. ISO-certified gate valves offer assurance of high quality and reliability, making them preferred choices for water system installations where performance and longevity are paramount. Investing in ISO-certified gate valves aligns with the goal of maintaining efficient and sustainable water infrastructure.

By understanding and prioritizing AWWA standards, NSF/ANSI certifications, and ISO compliance in the selection of gate valves, water industry professionals can contribute to the resilience and safety of water systems. These standards and certifications serve as essential benchmarks for ensuring the integrity and performance of gate valves in water applications.

Choosing the Right Gate Valve for Water System

Assessing the Water System’s Requirements

When selecting a gate valve for a water system, it’s crucial to first assess the specific requirements of the system. Consider factors such as water pressure, flow rate, and the type of water being transported. Understanding these requirements will help determine the appropriate size, material, and design of the gate valve needed to ensure optimal performance and longevity.

Factors to Consider Before Making a Purchase

Before making a purchase, there are several important factors to consider. These include the operating conditions of the water system, such as temperature and pressure ranges, as well as the frequency of operation. Additionally, the compatibility of the gate valve with the existing piping system and any applicable industry standards or regulations should be carefully evaluated. Taking these factors into account will help narrow down the options and guide the selection process towards the most suitable gate valve for the water system.

Sources for Quality Gate Valves

When seeking quality gate valves for water system, it’s essential to explore reputable sources. Authorized distributors and manufacturers with a proven track record of producing reliable and durable gate valves should be the primary focus. Additionally, considering customer reviews, product certifications, and warranty offerings can provide valuable insights into the overall quality and reliability of the gate valves available in the market. By sourcing gate valves from trusted suppliers, water system operators can ensure the long-term effectiveness and efficiency of their systems.

Conclusion on Gate Valves for Water Applications

When it comes to controlling the flow of water in a fluid system, gate valves play a crucial role. Their simple yet effective design makes them a reliable choice for regulating water flow. With their ability to fully open or close, gate valves provide a tight seal that minimizes leakage. Additionally, their durability and low maintenance requirements make them a cost-effective solution for water control in various applications. Understanding the benefits and functionality of gate valves for water is essential for ensuring efficient water management in residential, commercial, and industrial settings.